The Role of the BMS in Modern Lithium Batteries – Why It

Jul 23, 2025 · Modern lithium batteries are no longer simple storage units; they are intelligent energy systems designed to deliver safe, efficient, and lasting performance. At the heart of

Understanding Battery Management Systems (BMS):

Jan 18, 2025 · A Battery Management System (BMS) plays a crucial role in modern energy storage and electrification applications. It oversees a battery pack''s operational health,

Battery Management System (BMS) Maintenance for Rack Batteries

Jul 14, 2025 · What does BMS maintenance for rack batteries involve? BMS maintenance focuses on cell balancing, thermal regulation, and firmware integrity. Technicians calibrate voltage

Batteries in Parallel vs Series, All You Need to

Jan 20, 2024 · What Happens When Batteries Are Wired in Series? Wiring in series connects the positive terminal of one battery to the negative of the next,

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Eliminate the power difference between battery cells and avoid the "barrel effect". 2、 How does BMS work? Step by step analysis. 1. Data collection: Battery stethoscope.

Battery BMS Meaning and How It Reduces Maintenance

Aug 11, 2025 · Battery BMS Meaning and How It Reduces Maintenance Costs for Energy Storage Systems Energy storage systems (ESS) have emerged as a crucial component for power

Power Up: The Essential Role of Battery Management

Jul 19, 2025 · Integrating AI and IoT technologies into BMS is a significant trend, improving predictive maintenance, energy management, and performance monitoring of battery systems.

Battery BMS Meaning and How It Reduces Maintenance

Aug 11, 2025 · Through sophisticated protection and monitoring methods, a BMS lowers the total cost of ownership while guaranteeing the battery pack''s longevity, safety, and efficiency. 1.

The Role of BMS for Lithium Ion Batteries in Optimizing

May 27, 2025 · The Battery Management System (BMS) is essential to making sure these batteries run effectively, consistently, and safely. In particular, a well-thought-out maintenance

Battery Management System (BMS): Enhancing Battery

Mar 9, 2025 · Discover how Battery Management Systems (BMS) optimize battery efficiency, ensure safety, and extend battery life in EVs, electronics, and energy storage.

6 FAQs about [Monrovia Power Battery BMS Maintenance]

What is a battery management system (BMS)?

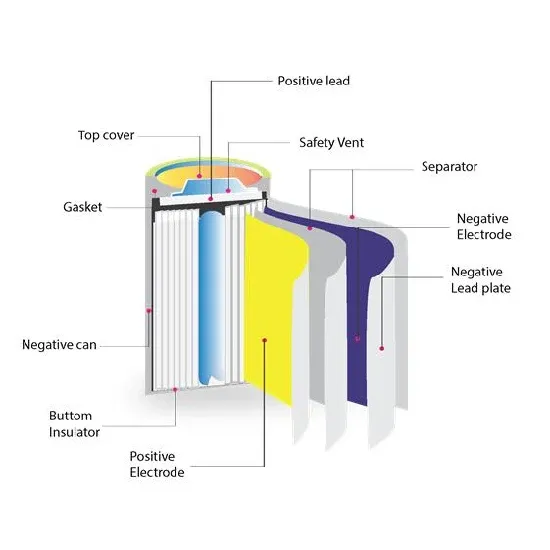

Battery technology has advanced significantly in recent years, with lithium batteries becoming the preferred choice for many applications, from renewable energy storage to marine and RV power solutions. However, to maximize performance and safety, a Battery Management System (BMS) is a critical battery system component.

How will BMS technology change the future of battery management?

As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving. The integration of AI, IoT, and smart-grid connectivity will shape the next generation of battery management systems, making them more efficient, reliable, and intelligent.

What makes a good battery management system?

A BMS must be designed for specific battery chemistries such as: 02. Power Consumption: An efficient BMS should consume minimal power to prevent draining the battery unnecessarily. 03. Scalability: For large-scale applications (EVs, grid storage), a scalable BMS is essential.

How does a battery management system work?

Based on these calculations, the BMS can take appropriate actions, such as regulating charging and discharging rates, activating cooling systems, or initiating cell balancing routines. It also communicates with the host system (e.g., a vehicle’s control unit or a power management system) to provide battery status updates and receive commands.

What are the different types of battery management systems?

2. Modular BMS: This architecture divides the battery pack into smaller modules, each with its own BMS controller. These modules communicate with a central master controller, offering improved scalability and redundancy. 3. Distributed BMS: In a distributed BMS, each battery cell or small group of cells has its own dedicated management circuit.

What is BMS & why is it important?

BMS is the “nerve center” of the battery system, and its technological level directly determines the safety, lifespan, and performance of the battery. With the outbreak of the new energy industry, BMS is rapidly evolving towards a more intelligent, precise, and reliable direction.

Learn More

- BMS in power battery refers to

- Naypyidaw BMS battery management power system enterprise

- Austria BMS battery management power system company

- Power lithium battery bms system

- Three-level topology of power storage battery BMs

- BMS Battery Management Power Systems Abu Dhabi

- Bandar Seri Begawan outdoor power lithium battery bms wholesale

- Battery energy storage system power generation in the communication base station room

- Austrian energy storage lithium battery bms

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.