Install Outdoor PoE Switch with Fiber Optical Cable

Jul 30, 2020 · To solve this problem, PoE Switch with fiber optic feature is one of the practical solutions. Its connection between the main control room and PoE

Fiber Optic Repeater Station Solutions

Currently, most solutions involve building or relocating new base stations, which greatly increase operators'' investment costs. A 5G high-power repeater station can effectively solve these

Fiber-To-The-Antenna (FTTA) — EITC

Aug 15, 2009 · Fiber-to-the-Antenna (FTTA) is a broadband network architecture in which optical fiber is used to connect the remote radio head (RRH) to the base station in new antennas, or

Setting up the FRITZ!Repeater for use with a fibre optic

1 Connecting the FRITZ!Repeater with the fibre optic modem Insert one end of a network cable into the LAN socket on the FRITZ!Repeater power adapter and the other end into the LAN

Modicon Fiber Optic Repeaters User''s Guide

Oct 12, 2020 · The Repeater contains one Fiber Optic Transceiver and one electrical interface for Modbus Plus. Models 490NRP254 and NWFR85D200 provide Fiber Optic Bus and electrical

GPS/GNSS Optical Repeater Solutions

Aug 5, 2025 · The Repeater solution consists of an active outdoor receive antenna, an outdoor rated transmit unit and a compact repeater unit with adjustable RF gain, and indoor ceiling

Use fiber optic repeater to optimize the CDMA mobile

Dec 3, 2021 · In the uplink path, the mobile phone signals of the mobile stations in the coverage area are processed by the uplink amplification link and transmitted to the corresponding base

Understanding Cell Phone Boosters for Rural

Aug 4, 2025 · In a fiber optic repeater system, the receiving end of the cell signal from the base station is called the near-end unit, and the amplifying end at the

Proforma Invoice No

Feb 22, 2017 · The EMTS Fiber optic repeating system is a cost-effective and practical solution for extending signal coverage in subways, tunnels and Indoor or outdoor distribution systems.

How to Get Internet to a Shed, Garage, or Barn (2025)

Oct 2, 2024 · The simplest way to connect to buildings wirelessly is via a Wi-Fi repeater (range extender). A Wi-Fi repeater connects to your Wi-Fi devices and a Wi-Fi router in your home

6 FAQs about [How to connect outdoor fiber optic repeater base station]

How to connect outdoor Olt to a fiber distribution network?

Fiber Optic Connectivity: Install fiber optic cables to connect the outdoor OLT to the fiber distribution network. Proper cable management techniques should be employed to minimize signal loss and maintain cable integrity. 5.

How do I install a fiber optic repeater?

Fiber Optic Repeater models are available for installation into a standard 19-inch rack. Your choice of mounting method should provide access to the Repeater for observing its status indicators. You should also locate the unit for easy access to its rear panel connectors, for ease of installation and future servicing.

How does a fiber optic repeater work?

The fiber optic cable is connected to the fiber optic ports by a low–loss, industrial ST–type connector. All of the repeaters are passive, meaning there is no regeneration of the received signal in the repeater, and no additional delay to the signal produced by the repeater.

What are the characteristics of optical fiber repeaters?

Fiber optic repeaters transmit through optical fibers, while wireless repeaters Spread through space. Therefore, the optical fiber repeater has the following characteristics: ①The frequency of the output signal is the same as that of the input signal, and the channel is transparent.

What is a nwfr85d200 repeater?

The Repeater contains one Fiber Optic Transceiver and one electrical interface for Modbus Plus. Models 490NRP254 and NWFR85D200 provide Fiber Optic Bus and electrical Line-Drop links between Modbus Plus nodes or network segments. Each Repeater contains two Fiber Optic Transceivers and one electrical Modbus Plus interface.

How many dB does a fiber optic repeater lose?

The distance between the two Repeaters is limited by the maximum allowable power loss from end to end. Power loss includes the fiber optic cable attenuation, connector losses at the Fiber Optic Receiver and Transmitter ports, and the system margin of 3 dB.

Learn More

- How to connect 4g outdoor base station to wireless network

- How to build a communication base station inverter and connect it to the grid at sea

- Fiber optic communication terminal base station set up 6 25MWh

- How to connect the energy storage power supply of the communication base station

- How to connect the signal base station battery to the power distribution cabinet

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- How to connect to the communication base station and wind and solar hybrid

- How to connect the leads of the base station power cabinet

- Which wireless outdoor base station manufacturers are there

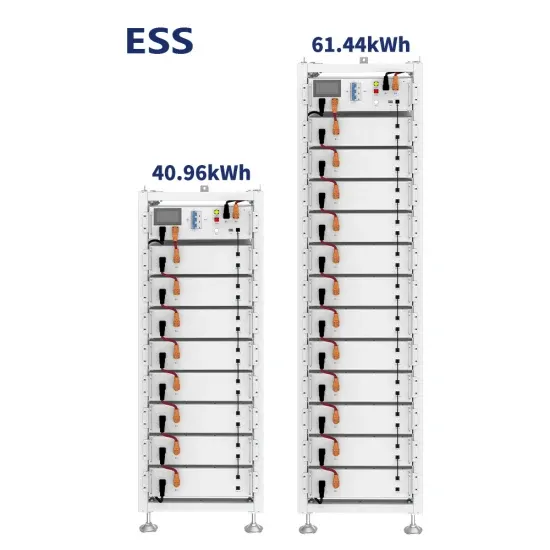

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.