How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

How Do 14.8V Li-Ion Battery Packs Work and Where Are

Mar 7, 2025 · A 14.8V Li-Ion battery pack combines four 3.7V cells in series (4S configuration) to deliver high energy density and stable power for devices like drones, power tools, and medical

Lithium Ion Battery 6600mAh 14.8V Production Enterprise

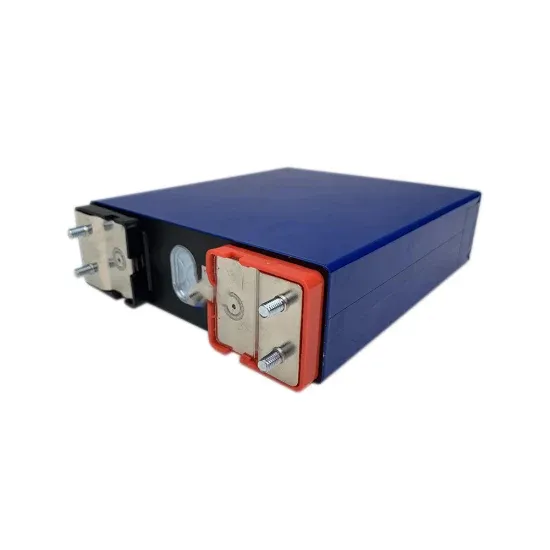

Lithium Battery Pack Characteristic 1.High Energy Density 2.Low Self Discharge Rate 3. Long Battery Life Circle up to 500 4.Wide Operation Temperature -20℃ ~+60℃ 5.Temperature

Lithium-ion Rechargeable Battery Pack

Oct 28, 2015 · 1. Preface This specification describes the type and size, performance, technical characteristics, warning and caution of the 12.8V 65Ah LiFePO4 rechargeable pack.

Three battery pack production process diagram

production will help you become prepared By summarizing and analyzing the actual production process of power battery pack, the process flow of automatic flexible assembly line of power.

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production. In this article, we will explore the world of battery

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

14.8V Lithium Polymer Batteries 4s lipo Packs for Tools,

Jun 27, 2025 · The engineering-level overview of 14.8V Lithium Polymer Batteries 4s lipo Packs: cell configuration, discharge performance, safety features, and comparison with traditional

14.8V 26Ah Lithium Ion Battery Production Company

Description XUANSN 14.8V 26Ah Lithium Battery has the highest power density of any rechargeable battery chemistry. It is lightweight and offers great cycle life even more than 500

Long Cycle Life High Temperature NiCd 4.8V AA 800mAh

High quality Long Cycle Life High Temperature NiCd 4.8V AA 800mAh Rechargeable Battery Pack For Emergency Lighting from China, China''s leading Rechargeable NiCd Battery product

14.8V 26Ah Lithium Ion Battery Production Company

Lithium Battery Pack Characteristic 1.High Energy Density 2.Low Self Discharge Rate 3. Long Battery Life Circle up to 500 4.Wide Operation Temperature -20℃ ~+60℃ 5.Temperature

14.8V 2600mAh Lithium Ion Battery Production

Lithium Battery Pack Characteristic 1.High Energy Density 2.Low Self Discharge Rate 3. Long Battery Life Circle up to 500 4.Wide Operation Temperature -20℃ ~+60℃ 5.Temperature

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · The manufacturing of lithium-ion battery packs is a highly precise and controlled process that plays a pivotal role in delivering reliable and high

14.8V 2600mAh Li-ion Battery Production Company

XUANSN has the capability to custom design a Lithium Ion battery pack to fit your product''s specific needs. From small single-cell packs to large battery packs, XUANSN can design safe

6 FAQs about [Production of 4 8v lithium battery pack]

What is the production process of a lithium-ion battery cell?

The ‘Production Process of a Lithium-Ion Battery Cell’ guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode manufacturing to cell assembly and cell finishing. Furthermore, current trends and innovation of different process technologies are also explained.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

How a lithium ion battery is made?

The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries. The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap.

How is Industry 4.0 transforming battery pack manufacturing?

Manufacturing innovations are revolutionizing production efficiency: Industry 4.0 integration enables real-time monitoring and adaptive process control throughout battery pack assembly, significantly reducing defect rates while improving traceability. Emerging technologies will transform battery pack manufacturing:

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

Learn More

- 4-cell 24v lithium battery pack production

- 36v4a lithium battery pack production

- 18V 2A lithium battery pack

- 60v lithium battery pack customization in Gothenburg Sweden

- Ten-series and three-parallel lithium battery pack

- 3 2v lithium battery to 12v lithium battery pack

- Morocco Casablanca large single lithium battery pack

- Xia flashlight lithium battery pack price

- 37 23kwh lithium battery pack in Bergen Norway

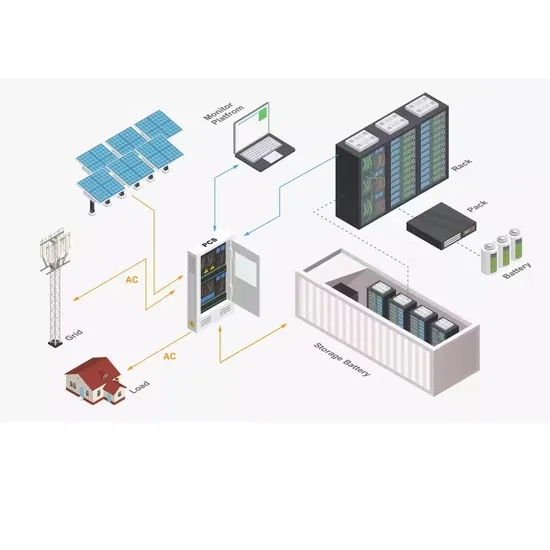

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.