3.2V LiFePO4 Cell Configurations To Build 12V, 24V & 48V

Jul 7, 2023 · Below you can see the most common configuration using LiFePO4 cells to build 12V, 24V and 48V battery pack. Among the different LiFePO4 pack configurations, both a 15-cell

How to Make a 12V 4000mAh Lithium Battery

Aug 10, 2024 · Constructing a custom battery pack allows for flexibility in voltage and capacity, making it suitable for specific needs. This report outlines the

The Complete Guide to Lithium-Ion Battery

Nov 14, 2023 · For a 12V lithium-ion battery (which is typically made up of 4 cells in series), 13.2V indicates a charge level of about 70-80%, which is generally

Quality Lithium Battery & Portable Generator factory from

Guangdong beineng New Energy Co., Ltd. KingKong battery now have enough stock in China/Poland EU/US/CA/UK location for the (1) 3.2V LiFePO4 cell (2) 12V LiFePO4 battery

How to make a 12 volt lithium-ion battery pack?

Nov 14, 2024 · Building a 12V lithium-ion battery pack can be a rewarding DIY project, providing you with a reliable power source for various applications. To

DIY LiFePO4 Battery Pack : 14 Steps (with Pictures)

In this Instructable, I will show you, how to make a LiFePO4 Battery Pack for applications like Off-Grid Solar System, Solar Generator, Electric Vehicle, Power wall, etc. The fundamental is very

DIY LiFePO4 Battery Pack: Step-by-Step Guide (2025 Update

Apr 18, 2025 · Whether you''re powering a solar setup, campervan, or DIY project, this guide reveals how to assemble a LiFePO4 battery pack optimized for performance, safety, and

Eve Lithium LiFePO4 Battery 3.2V 100ah Cell for

Aug 5, 2025 · 1.Wide range of lithium batteries (3.2v-72v, 5ah-500ah) to choose from. 2 e high quality a grade prismatic cells. More than 3000 cycle life. Up

CATL 3.2V 200ah Lifepo4 Battery Cell for DIY Battery Packs

CATL Full New 3.2V 200Ah LiFePO4 Battery Cell for DIY 12V 24V 48V 200Ah Solar Lithium Li Ion LFP Battery Pack. Ideal for electric power systems and solar energy storage.| Alibaba

6 FAQs about [3 2v lithium battery to 12v lithium battery pack]

What materials do I need to build a 12V lithium battery pack?

To build a 12V lithium battery pack, you will need the following materials: Wholesale lithium golf cart batteries with 10-year life? Check here. Lithium-Ion Cells: Commonly used cells include 18650 or LiFePO4 cells. Battery Management System (BMS): This device monitors and manages the charging and discharging of the battery.

How do I assemble a 12V battery pack?

Assembling your battery pack involves several steps: Determine Configuration: For a 12V pack, connect cells in series. Typically, you will need four cells in series if using LiFePO4 (3.2V per cell) or three cells if using standard lithium-ion cells (3.7V per cell).

What are the different types of battery packs?

Generally speaking, 12V, 24V and 48V battery packs are more popular with battery DIY enthusiasts. These three types of battery packs can satisfy most devices. Since the voltage of a single LiFePO4 battery is 3.2V, series and parallel connections are required to complete a suitable battery pack.

What are the different types of LiFePO4 battery packs?

The most commonly used packs are 12V, 24V and 48V. Below you can see the most common configuration using LiFePO4 cells to build 12V, 24V and 48V battery pack. Among the different LiFePO4 pack configurations, both a 15-cell 48V pack and a 16-cell 51.2V pack are commonly used.

What is the nominal voltage of a battery pack?

The desired nominal voltage of the battery pack is 12.8V. The nominal voltage of each cell = 3.2 V No of cells required for series connection = 12.8 /3.2 = 4nos Commonly cells in series are abbreviated in terms of ‘S’, so this pack will be known as a “4S pack”.

How to choose a battery pack?

When building battery pack, consider the target voltage/capacity/use purpose, and the connection method of the battery is the way to achieve these differences. Generally speaking, 12V, 24V and 48V battery packs are more popular with battery DIY enthusiasts. These three types of battery packs can satisfy most devices.

Learn More

- 100A 12V lithium battery pack

- 12v lithium battery pack 30000 mAh

- Montevideo 12v lithium battery pack

- North Korea 12v battery pack lithium battery

- Tonga 12v lithium battery pack

- Lithium battery pack 12v inverter

- Khartoum RV lithium battery pack

- Electric flat car lithium battery pack

- Vienna lithium battery pack

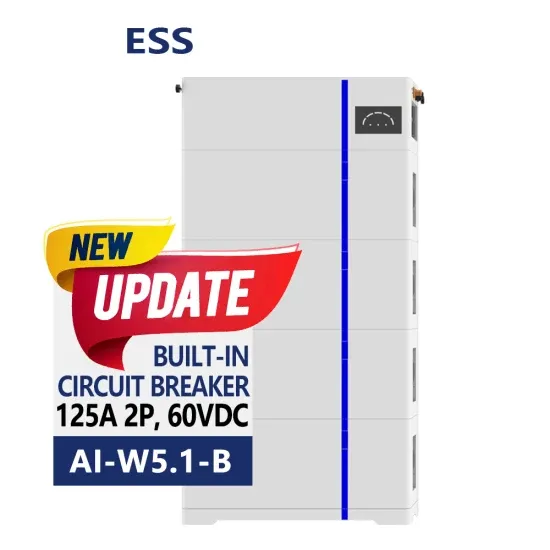

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.