doha haiti all-vanadium liquid flow energy storage pump

A comparative study of iron-vanadium and all-vanadium flow battery for large scale energy storage A typical case of a 1 MW/4h flow battery system is selected for the comparison of

Aramco: World First MW-Scale Flow Battery for Solar Storage

May 27, 2025 · Aramco has developed a flow battery for solar storage in collaboration with Rongke Power - Credit: Rongke Power Aramco''s MW-scale Iron-Vanadium flow battery is

Next-generation vanadium redox flow batteries: harnessing

Apr 25, 2025 · Abstract Vanadium redox flow batteries (VRFBs) have emerged as a promising contenders in the field of electrochemical energy storage primarily due to their excellent

FAQ | Vanadium Redox Flow Battery | Sumitomo Electric

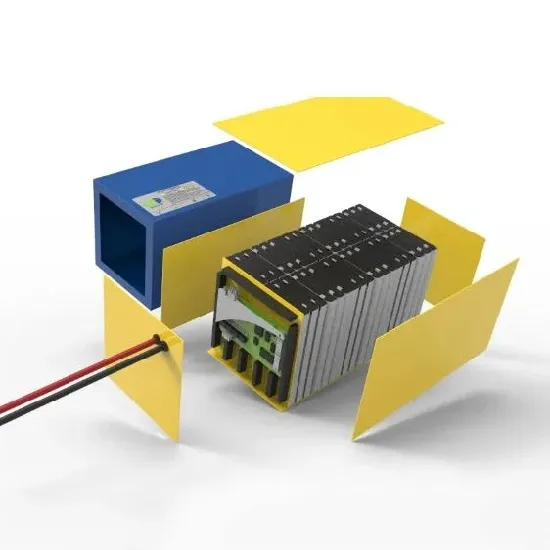

Aug 13, 2025 · Frequently Asked Questions How is the Vanadium Redox Flow Battery system configured? The basic components include a cell stack (layered liquid redox cells), an

Global electrolyte standard ''crucial for scalability

Mar 11, 2025 · Global standards and specifications for the electrolyte used in vanadium redox flow batteries are "crucial" for the technology''s prospects.

Dynamic modeling of all-vanadium flow battery

The model is applied to study the effects of current, electrolyte flow rate and temperature on the charge and discharge characteristics. Key words: all-vanadium flow battery, dynamic model,

Aramco Becomes First in the World to Operate Advanced

3 days ago · This marks the first global use of an iron-vanadium flow battery as a solar energy backup for gas well operations. The 1-megawatt-hour flow battery system in Wa''ad Al Shamal

World''s first commercial iron/vanadium flow battery system

Aug 5, 2025 · Saudi Aramco has achieved a world first by deploying a megawatt-scale iron/vanadium (Fe/V) flow battery system to power natural gas production activities, setting a

Vanadium batteries

Jan 1, 2021 · The liquid with active substances is continuously circulated. The active material of vanadium liquid flow batteries is stored in liquid form in the external storage tank. The flow of

Vanadium Liquid Flow Energy Storage Battery Pump

Vanadium Liquid Flow Energy Storage Battery Pump Vanadium redox flow batteries (VRFBs) are the best choice for large-scale stationary energy storage because of its unique energy storage

Vanadium flow batteries at variable flow rates

Jan 1, 2022 · Vanadium flow batteries employ all-vanadium electrolytes that are stored in external tanks feeding stack cells through dedicated pumps. These batteries can possess near limitless

What Are Flow Batteries? A Beginner''s Overview

Jan 14, 2025 · Flow batteries have a storied history that dates back to the 1970s when researchers began experimenting with liquid-based energy storage solutions. The

Aramco: World First MW-Scale Flow Battery for Solar Storage

May 27, 2025 · Aramco has successfully commissioned the world''s first megawatt-scale Iron-Vanadium (Fe/V) flow battery. This battery is set to store solar energy to provide a backup

renewable energy storage system for gas operations

May 22, 2025 · Flow batteries store energy in liquid electrolytes separately from battery cells, and electrolytes pumped into the cell convert chemical energy into electricity. In addition to

全钒液流电池在充电结束搁置阶段的开路电压变化

Dec 30, 2021 · 关键词: 全钒液流电池, 开路电压, 非液流储能电池 Abstract: Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate

Towards a high efficiency and low-cost aqueous redox flow battery

May 1, 2024 · The factors affecting the performance of flow batteries are analyzed and discussed, along with the feasible means of improvement and the cost of different types of flow batteries,

Technology Strategy Assessment

Jan 12, 2023 · A total of 22 industry attendees representing 14 commercial flow battery-related companies (i.e., 5 organic-based, 3 vanadium-based, 2 zinc-based, 1 iron-based, 1 sulfur

madagascar haiti all-vanadium liquid flow energy storage

Electrodes for All-Vanadium Redox Flow Batteries | SpringerLink The flow battery with Mn 3 O 4 –CC electrode exhibited an energy efficiency of 88% at 100 mA cm −2 and even up to 71.2%

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

Riyadh All-vanadium Liquid Flow Battery Pump

Of the various types of flow batteries, the all-liquid vanadium redox flow battery (VRFB) has received most attention from researchers and energy promoters for medium and large-scale

Aramco deploys world-first Fe-V flow battery for gas well

Jun 1, 2025 · Aramco, a leading integrated energy and chemicals company, has achieved a world-first by successfully commissioning a megawatt (MW)-scale renewable energy storage

Products and Smart Manufacturing | YinFeng

Hunan Yinfeng New Energy Co., Ltd., established in 2013, is a high-tech enterprise focusing on the research, development, manufacturing and commercial application of a new type of high

all-vanadium liquid flow energy storage pump

Huo et al. demonstrate a vanadium-chromium redox flow battery that combines the merits of all-vanadium and iron-chromium redox flow batteries. The developed system with high theoretical

Haiti all-vanadium liquid flow energy storage pump

The all-vanadium flow batteries have gained widespread use in the field of energy storage due to their long lifespan, high efficiency, and safety features. However, in order to further advance

Saudi Arabia All-Vanadium Liquid Flow Energy Storage

Deal concludes for Saudi Arabian GW-scale vanadium redox battery facility The JV will see the partners produce Vanadium Redox Flow Batteries (VRFB) through the jointly-formed Advance

What Is ESS Inc Flow Battery?

Jun 6, 2025 · What are the core components of an ESS flow battery? ESS flow batteries comprise electrolyte tanks, cell stacks, and pump systems. The tanks hold charged/uncharged

Aramco achieves world-first in gas operations, boosts

May 22, 2025 · Riyadh – Mubasher: Saudi Arabian Oil Company (Aramco) has unveiled a world-first milestone by successfully commissioning a megawatt (MW)-scale renewable energy

Long term performance evaluation of a commercial vanadium flow battery

Jun 15, 2024 · This demonstrates the advantage that the flow batteries employing vanadium chemistry have a very long cycle life. Furthermore, electrochemical impedance spectroscopy

Vanadium Flow Battery: How It Works and Its Role in Energy

Mar 3, 2025 · A vanadium flow battery works by circulating two liquid electrolytes, the anolyte and catholyte, containing vanadium ions. During the charging process, an ion exchange happens

Aramco Unveils World''s First Megawatt-Scale Flow Battery

May 26, 2025 · Saudi Arabia''s Aramco has introduced a groundbreaking renewable energy storage system using an Iron-Vanadium flow battery to support gas production in Wa''ad Al

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · Compared with the all-vanadium flow battery, since the vanadium/air single flow battery uses an air/oxygen diffusion electrode to replace the flow positive half-cell, the amount

3 FAQs about [Riyadh All-vanadium Liquid Flow Battery Pump]

Where is Aramco Fe/V flow battery located?

This Fe/V flow battery is located in Wa’ad Al-Shamal, in western Saudi Arabia. It can deliver a MW/hour and support up to five wells across its projected 25 year lifespan. Aramco says that the system “offers a robust alternative to existing solar energy solutions and can handle variable power demands efficiently and cost-effectively.”

What is Aramco's flow battery system?

The flow battery system is based on Aramco’s patented technology and developed in collaboration with Rongke Power. Ali A. Al-Meshari, Senior Vice President of Technology Oversight and Coordination at Aramco, says: "The pioneering flow battery system spearheaded by Aramco’s researchers represents a breakthrough for the oil and gas industry.

How do flow batteries work?

Flow batteries store energy in liquid electrolytes held in external tanks. Electrolytes pumped into a battery cell convert chemical energy into electricity. These batteries can be repeatedly recharged and discharged with minimal capacity loss and reduce fire risks compared to other types of batteries.

Learn More

- All-vanadium liquid flow battery device

- Ouagadougou all-vanadium liquid flow battery

- Sukhumi All-vanadium Liquid Flow Battery

- Average voltage of all-vanadium liquid flow battery

- Vientiane All-vanadium Liquid Flow Battery Environment

- The right is the all-vanadium liquid flow energy storage battery

- Africa s new all-vanadium liquid flow battery

- Kuala Lumpur All-vanadium Liquid Flow Battery

- Feasibility of all-vanadium liquid flow battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.