A Review of Capacity Decay Studies of All‐vanadium

Aug 13, 2024 · This review generally overview the problems related to the capacity attenuation of all-vanadium flow batteries, which is of great significance for understanding the mechanism

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Abstract Vanadium redox flow batteries (VRFB) are gradually becoming an important support to address the serious limitations of renewable energy development. The

Vanadium electrolyte: the ''fuel'' for long-duration

May 22, 2023 · Image: CellCube. Samantha McGahan of Australian Vanadium writes about the liquid electrolyte which is the single most important material

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · Exposure of the polymeric membrane to the highly oxidative and acidic environment of the vanadium electrolyte can result in membrane deterioration. Furthermore, poor

全钒液流电池容量衰减机理的研究_刘帅舟

Oct 16, 2019 · Meanwhile, other factors, such as environment andmaterials, which may accelerate the cell capacity decay, are analyzed.Key words:all vanadium liquid flow battery; capacity

Vanadium Redox Flow Batteries

Jul 30, 2023 · Introduction Vanadium redox flow battery (VRFB) technology is a leading energy storage option. Although lithium-ion (Li-ion) still leads the industry in deployed capacity,

Vietnam All-vanadium Liquid Flow Energy Storage

The environmental impact of both the vanadium redox battery (vanadium battery) and the lead-acid battery for use in stationary applications has been evaluated using a life cycle

China to host 1.6 GW vanadium flow battery

Sep 23, 2024 · The all-vanadium liquid flow industrial park project is taking shape in the Baotou city in the Inner Mongolia autonomous region of China, backed

All-vanadium liquid flow battery investment

Dalian Rongke Power has connected a 100 MW redox flow battery storage system to the grid in Dalian, China. It will start operating in mid-October and will eventually be scaled up to 200

Development status, challenges, and perspectives of key

Dec 1, 2024 · As an important branch of RFBs, all-vanadium RFBs (VRFBs) have become the most commercialized and technologically mature batteries among current RFBs due to their

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · Compared with the all-vanadium flow battery, since the vanadium/air single flow battery uses an air/oxygen diffusion electrode to replace the flow positive half-cell, the amount

Vanadium Battery | Energy Storage Sub-Segment – Flow Battery

Jun 30, 2025 · All-vanadium flow battery, full name is all-vanadium redox battery (VRB), also known as vanadium battery, is a type of flow battery, a liquid redox renewable battery with

Sichuan V-LiQuid Energy Co., Ltd.

V-Liquid is a developer and manufacturer specializing in all-vanadium flow battery technology. We focus on the research, development, production, and sales of core materials, electric stacks,

Vanadium batteries

Jan 1, 2021 · The liquid with active substances is continuously circulated. The active material of vanadium liquid flow batteries is stored in liquid form in the external storage tank. The flow of

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · First of all, the battery capacity and output power is relatively independent, the battery capacity depends only on the electrolyte concentration and the amount of electrolyte,

Principle, Advantages and Challenges of Vanadium Redox Flow Batteries

Nov 26, 2024 · Reproduction of the 2019 General Commissioner for Schematic diagram of a vanadium flow-through batteries storing the energy produced by photovoltaic panels.

All-vanadium liquid flow energy storage battery equipment

Cost structure analysis and efficiency improvement and cost As the most mature liquid flow battery, all vanadium flow battery has developed rapidly in the direction of energy storage.

all-vanadium liquid flow energy storage battery production

A vanadium-chromium redox flow battery toward sustainable energy storage Highlights. •. A vanadium-chromium redox flow battery is demonstrated for large-scale energy storage. •. The

What is all-vanadium liquid flow battery energy storage?

Feb 11, 2024 · What is all-vanadium liquid flow battery energy storage? 1. All-vanadium liquid flow batteries utilize a unique electrochemical process for energy storage, specifically leveraging

Prospects for industrial vanadium flow batteries

Jul 15, 2023 · Vanadium Flow Batteries (VFBs) are a stationary energy storage technology, that can play a pivotal role in the integration of renewable sources into t

Vanadium Redox Flow Batteries

Jul 30, 2023 · Flow batteries are durable and have a long lifespan, low operating costs, safe operation, and a low environmental impact in manufacturing and recycling. The technology

How about Kaifeng all-vanadium liquid flow energy storage

May 7, 2024 · All-vanadium liquid flow systems offer notable advantages compared to lithium-ion batteries, particularly in terms of lifespan and sustainability. Lithium-ion batteries typically

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Dec 6, 2012 · Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in both tanks, exploiting vanadium''s ability to exist in several states. By using one

Vietnam All-vanadium Liquid Flow Energy Storage

The environmental impact of both the vanadium redox battery (vanadium battery) and the lead-acid battery for use in stationary applications has been evaluated using a life

A Wide‐Temperature‐Range Electrolyte for all Vanadium Flow Batteries

Jun 4, 2025 · The all-vanadium flow battery (VFB) has emerged as a highly promising large-scale, long-duration energy storage technology due to its inherent advantages, including decoupling

Development status, challenges, and perspectives of key

Dec 1, 2024 · Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

全钒液流电池在充电结束搁置阶段的开路电压变化

Dec 30, 2021 · 关键词: 全钒液流电池, 开路电压, 非液流储能电池 Abstract: Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate

Iron-vanadium redox flow batteries electrolytes: performance

Nov 10, 2024 · Performance comparison of all-vanadium and DES electrolytes in vanadium redox flow batteries. (a)Full-cell test platform; (b) Coulombic and voltage efficiencies over 20 cycles;

6 FAQs about [Vientiane All-vanadium Liquid Flow Battery Environment]

Are vanadium redox flow batteries viable?

Among these systems, vanadium redox flow batteries (VRFB) have garnered considerable attention due to their promising prospects for widespread utilization. The performance and economic viability of VRFB largely depend on their critical components, including membranes, electrodes, and electrolytes.

Will flow battery suppliers compete with metal alloy production to secure vanadium supply?

Traditionally, much of the global vanadium supply has been used to strengthen metal alloys such as steel. Because this vanadium application is still the leading driver for its production, it’s possible that flow battery suppliers will also have to compete with metal alloy production to secure vanadium supply.

Why are innovative membranes needed for vanadium redox flow batteries?

Innovative membranes are needed for vanadium redox flow batteries, in order to achieve the required criteria; i) cost reduction, ii) long cycle life, iii) high discharge rates and iv) high current densities. To achieve this, variety of materials were tested and reported in literature. 7.1. Zeolite membranes

Are all-vanadium RFB batteries safe?

As an important branch of RFBs, all-vanadium RFBs (VRFBs) have become the most commercialized and technologically mature batteries among current RFBs due to their intrinsic safety, no pollution, high energy efficiency, excellent charge and discharge performance, long cycle life, and excellent capacity-power decoupling .

Why are vanadium batteries so expensive?

Vanadium makes up a significantly higher percentage of the overall system cost compared with any single metal in other battery technologies and in addition to large fluctuations in price historically, its supply chain is less developed and can be more constrained than that of materials used in other battery technologies.

How efficient are flow batteries compared to Li-ion batteries?

Flow batteries average between 70%-85% round-trip efficiency, compared with 90%-95% average for Li-ion batteries, potentially affecting the economics of projects based around bulk shifting of energy.

Learn More

- Iranian all-vanadium liquid flow energy storage battery

- 50mw all-vanadium liquid flow battery energy storage power station

- Feasibility of all-vanadium liquid flow battery

- The right is the all-vanadium liquid flow energy storage battery

- 30kw all-vanadium liquid flow energy storage battery

- Africa s new all-vanadium liquid flow battery

- 1gw all-vanadium liquid flow battery energy storage

- Nanya Luojia Power Grid All-vanadium Liquid Flow Battery Energy Storage

- Benin All-vanadium Liquid Flow Battery

Industrial & Commercial Energy Storage Market Growth

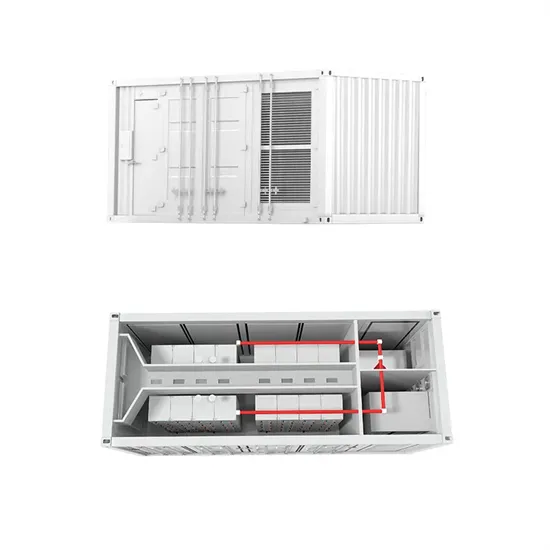

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

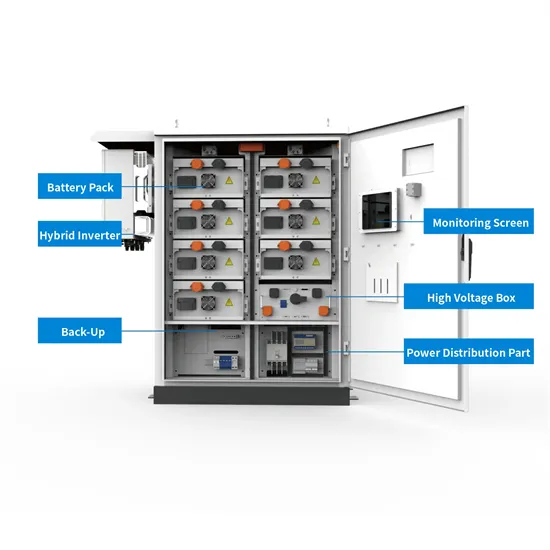

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.