Capital cost evaluation of conventional and emerging redox flow

Jan 1, 2023 · Redox flow battery (RFB) is a promising technology to store large amounts of energies in liquid electrolytes attributable to their unique architectures. In recent years, various

Preliminary Investigation into the Feasibility of an Ambient

Oct 1, 2024 · Rechargeable metal-air batteries are of great interest, as they can provide extremely high energy densities. Here, we describe our preliminary investigation into the feasibility of an

All-vanadium redox flow batteries

Jan 1, 2025 · The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it

Feasibility analysis of underground flow battery storage in

Sep 15, 2023 · The flow battery is an electrochemical energy storage technology proposed by Thaller in 1974 [11]. A conventional flow battery consists of two electrolyte storage tanks,

Research progress in preparation of electrolyte for all-vanadium

Feb 25, 2023 · All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · In 1976. research scholars found that vanadium can be used as the active substance of the liquid current battery; in 1958. scholars theoretically proved the feasibility of

FLORES-Policy-Brief_October-2021.pdf

Nov 10, 2021 · 65% of which are working on all-vanadium flow batteries. There is a strong flow battery industry in Europe and a large value chain already exists in Europe. Around 41% (17)

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for

Next-generation vanadium redox flow batteries: harnessing

Apr 25, 2025 · Vanadium redox flow batteries (VRFBs) have emerged as a promising contenders in the field of electrochemical energy storage primarily due to their excellent energy storage

Flow battery production: Materials selection and

Oct 1, 2020 · For example, harmonization of the battery system boundary led to freshwater eutrophication and freshwater ecotoxicity values for vanadium redox flow batteries lower than

A green europium-cerium redox flow battery with ultrahigh

Nov 15, 2024 · However, the main redox flow batteries like iron-chromium or all-vanadium flow batteries have the dilemma of low voltage and toxic active elements. In this study, a green Eu

Feasibility analysis of using salt caverns for storage of redox flow

Oct 26, 2020 · Two medium salt caverns in Jiangsu Province were selected and used as a case study for storage for the all-vanadium flow batteries. The working principle of salt cavern is

ALL-VANADIUM REDOX FLOW BATTERY

Nov 5, 2024 · Studies on the temperature stability of the electrolyte solution for the all-vanadium redox flow battery in the sulphuric acid system focus mainly on the high-temperature stability,

Exploring the Potential of Flow Batteries for Large-Scale

This paper explores the technological fundamentals, advantages, and challenges of flow batteries as a solution for large-scale energy storage. By focusing on different types of flow battery

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · Battery storage systems become increasingly more important to fulfil large demands in peaks of energy consumption due to the increasing supply of intermittent renewable energy.

A novel strategy toward high energy density: Liquid–solid

Feb 15, 2025 · Abstract The theoretical basis of liquid–solid two-phase chemical reaction (LTCR) for improving the energy density of flow batteries was first described based on the potential

Vanadium Redox Flow Batteries

Jul 30, 2023 · Introduction Vanadium redox flow battery (VRFB) technology is a leading energy storage option. Although lithium-ion (Li-ion) still leads the industry in deployed capacity,

Feasibility Study of All-Vanadium Liquid Flow Battery Key

Why All-Vanadium Flow Batteries Are Gaining Momentum As global demand for renewable energy storage solutions surges, the all-vanadium liquid flow battery (VRFB) has emerged as

Review—Preparation and modification of all-vanadium redox flow battery

Nov 21, 2024 · As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

Iron-vanadium redox flow batteries electrolytes: performance

Nov 10, 2024 · Performance comparison of all-vanadium and DES electrolytes in vanadium redox flow batteries. (a)Full-cell test platform; (b) Coulombic and voltage efficiencies over 20 cycles;

Feasibility Study of All-Vanadium Liquid Flow Battery Key

As global demand for renewable energy storage solutions surges, the all-vanadium liquid flow battery (VRFB) has emerged as a frontrunner. This feasibility study explores its technical

Design and development of large-scale vanadium redox flow batteries

Jan 30, 2024 · Vanadium redox flow battery (VRFB) energy storage systems have the advantages of flexible location, ensured safety, long durability, independent power and capacity

A review of bipolar plate materials and flow field designs in the all

Apr 1, 2022 · A bipolar plate (BP) is an essential and multifunctional component of the all-vanadium redox flow battery (VRFB). BP facilitates several functions in

Technical analysis of all-vanadium liquid flow batteries

In 1976. research scholars found that vanadium can be used as the active substance of the liquid current battery; in 1958. scholars theoretically proved the feasibility of vanadium batteries, and

Development of the all‐vanadium redox flow battery for

May 24, 2011 · Commercial systems are being applied to distributed systems utilising kW-scale renewable energy flows. Factors limiting the uptake of all-vanadium (and other) redox flow

6 FAQs about [Feasibility of all-vanadium liquid flow battery]

Are vanadium redox flow batteries a viable energy storage solution?

Vanadium redox flow batteries (VRFBs) hold great promise as a scalable and efficient energy storage solutions for renewable energy systems as compared to its several counterparts.

Will flow battery suppliers compete with metal alloy production to secure vanadium supply?

Traditionally, much of the global vanadium supply has been used to strengthen metal alloys such as steel. Because this vanadium application is still the leading driver for its production, it’s possible that flow battery suppliers will also have to compete with metal alloy production to secure vanadium supply.

Are all-vanadium RFB batteries safe?

As an important branch of RFBs, all-vanadium RFBs (VRFBs) have become the most commercialized and technologically mature batteries among current RFBs due to their intrinsic safety, no pollution, high energy efficiency, excellent charge and discharge performance, long cycle life, and excellent capacity-power decoupling .

What is vanadium redox flow battery (VRFB)?

Among the various types of RFBs, vanadium redox flow battery (VRFB) stands out for its ability to eliminate cross-contamination between electrolytes, a common issue in other flow battery chemistries which induces self-discharge of the device.

What membranes are used in vanadium flow batteries?

The membranes employed in vanadium flow batteries can be grouped into ion exchange membranes and physical separators; however, this topic will only focus on ion exchange membranes .

How efficient are flow batteries compared to Li-ion batteries?

Flow batteries average between 70%-85% round-trip efficiency, compared with 90%-95% average for Li-ion batteries, potentially affecting the economics of projects based around bulk shifting of energy.

Learn More

- Benin All-vanadium Liquid Flow Battery

- 1gw all-vanadium liquid flow battery energy storage

- The right is the all-vanadium liquid flow energy storage battery

- Nanya Luojia Power Grid All-vanadium Liquid Flow Battery Energy Storage

- All-vanadium liquid flow battery device

- All-vanadium liquid flow battery rate

- 50mw all-vanadium liquid flow battery energy storage power station

- Vientiane All-vanadium Liquid Flow Battery Environment

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

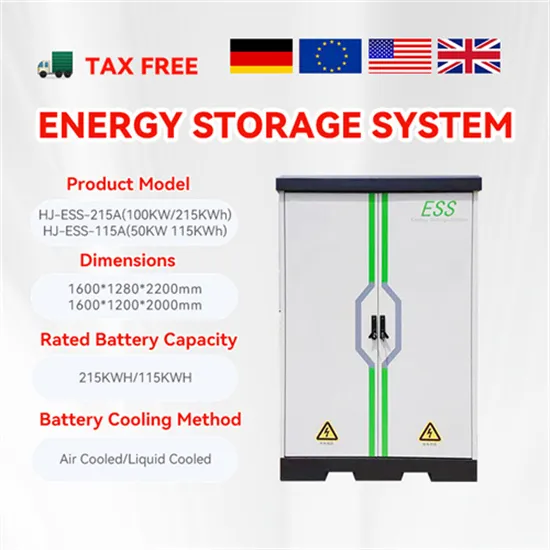

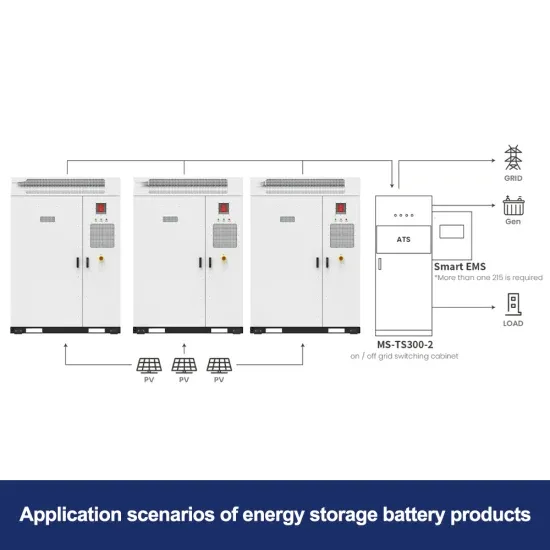

Industrial & Commercial Energy Storage Market Growth

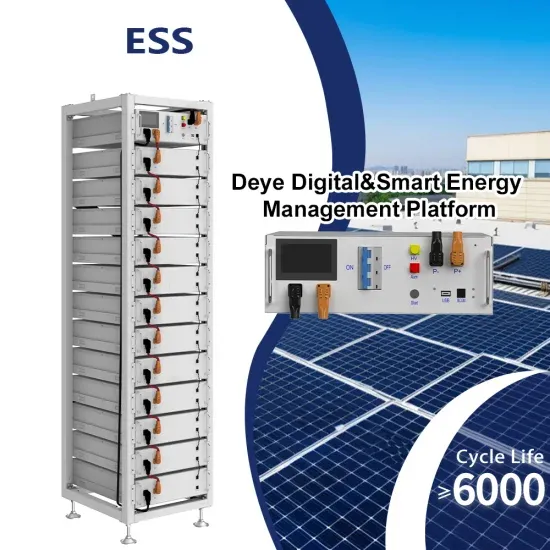

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

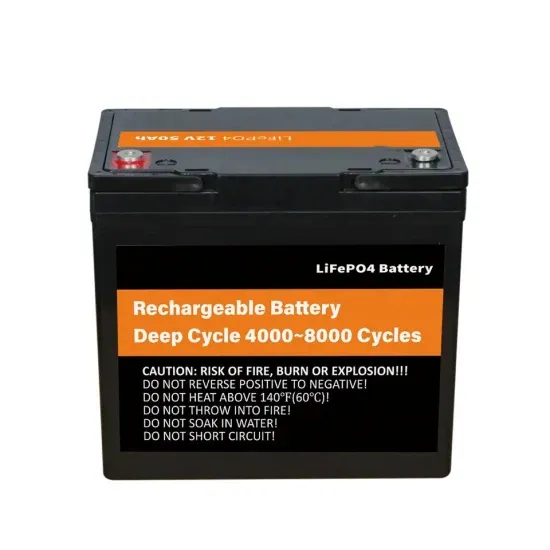

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.