Aluminum Electrolytic Capacitors Conductive Polymer

Aug 16, 2025 · 1. Introduction Capacitor is electronic component constructed electronic circuit. There are a variety of capacitors which have various materials and construction. Typical

Aluminum Electrolytic Capacitor Primer

Mar 21, 2024 · Electrolytic Capacitors, Basic Construction Aluminum electrolytic capacitors utilize an "anode" (+) electrode made of high-purity etched aluminum foil. The anode etching process

Porous aluminum supported carbon nanotubes-based 2.7 V

Jun 1, 2025 · Currently, aluminum electrolytic capacitors (AECs) are the dominating electronics for AC filtering but have low specific capacitance. Their large bulk often makes them the largest

Application Guide, Aluminum Electrolytic Capacitors

Apr 25, 2023 · This Application Guide This guide is a full handbook on aluminum electrolytic capacitors, of course with emphasis on Cornell Dubilier''s types. It covers construction in depth

Aluminum Electrolytic Capacitor Application Guide

Sep 17, 2018 · Aluminum Electrolytic Capacitor Application Guide This guide is a full handbook on aluminum electrolytic capacitors, of course with emphasis on Cornell Dubilier''s types. It covers

Aluminum Electrolytic Capacitors | Nippon Chemi-Con

What is an Aluminum Electrolytic Capacitor? Also called an electrolytic capacitor, this capacitor uses liquid electrolyte as the role of cathode and aluminum oxide as dielectric. It features a

Aluminum Electrolytic Capacitors for Industrial

Jan 28, 2022 · Aluminum Electrolytic Capacitors TDK Foil Italy/ Iceland (production of aluminum foil for Electrolytic Capacitors) TDK benefit Three capacitor factories on three continents and

Global and China Aluminum Electrolytic

Aug 15, 2019 · Chinese aluminum electrolytic capacitor market has been expanding amid a transfer of its downstream industries to China like home appliance illumination, cellphones and

Professional Electrolytic Capacitor Manufacturer

Aluminum electrolytic capacitors are made of anode aluminum foil, electrolytic paper, cathode aluminum foil, electrolytic paper, etc., which are stacked and wound in 4 layers; after the core

خرید خازن الکترولیتی آلومینیومی | انواع SMD و DIP

خازن الکترولیتی آلومینیومی(Aluminum Electrolytic Capacitor) یکی از پرکاربردترین انواع خازن ها در طراحی مدارات آنالوگ و دیجیتال است. این خازن ها از دو لایه آلومینیوم و یک الکترولیت مایع یا جامد تشکیل شده اند و به دلیل ظرفیت بالا، اندازه مناسب و قیمت

Electrolytic Capacitor | Capacitor Types

4 days ago · Electrolytic capacitor definition An electrolytic capacitor is a polarized capacitor which uses an electrolyte to achieve a larger capacitance than other

High-performance MIM-type aluminum electrolytic capacitors

Aug 1, 2024 · Abstract Capacitors are indispensable components of electronic circuits. Filter capacitors, mainly dominated by electrolytic capacitors, are critical for the accurate power

Capacitors for Military/Aerospace

Jul 26, 2023 · SMT offerings in both Aluminum Electrolytic and Low Loss Hybrid Polymer-Aluminum Electrolytic capacitors with vibration withstand of up to 30G, AEC-Q200 Compliant

Tehran inverter aluminum electrolytic capacitor

In the three-phase 380V inverter, 2 pieces 400VDC capacitors in series are usually used. Zeasset succeeds in developing one single aluminum electrolytic capacitor with voltage endurance up

Introduction, Basic Concepts, and Definitions: Aluminum

Jan 8, 2021 · capacitor The heat, generated by ripple current, is an important factor of influence for non-solid aluminum capacitors for calculating the useful life under certain circumstances.

6 FAQs about [Tehran Super Aluminum Electrolytic Capacitor]

What is an aluminum electrolytic capacitor?

Also called an electrolytic capacitor, this capacitor uses liquid electrolyte as the role of cathode and aluminum oxide as dielectric. It features a large capacitance by forming minute unevenness on the surface of aluminum foil through electrochemical treatment to enlarge the surface area.

What is the future of aluminum electrolytic capacitors?

With the technological upgrading of 5G communications, new energy vehicles and consumer electronics industries, the demand for miniaturized, chip-type and medium-high-voltage large-capacity aluminum electrolytic capacitors continues to expand, and there is a broader space for development.

What is a super capacitor?

The supercapacitor is a new type of component that stores energy through the interface double layer formed between the electrode and the electrolyte. Beryl is a professional capacitor manufacturer with 18 years of R&D experience in electrolytic capacitors, super capacitors, and so on.

What are the different types of electrolytic capacitors?

Super low ESR products, using solid conductive polymers instead of electrolytes, are also widely used. Hybrid capacitors, combining electrolyte and conductive polymers, have also emerged in recent years and aluminum electrolytic capacitors continue to evolve to provide optimal characteristics tailored to the conditions of use.

How much money will aluminum electrolytic capacitors make a year?

After the completion of the project, it is expected to achieve annual sales of 2.5 billion yuan and annual profits and taxes of over 500 million yuan. Aluminum electrolytic capacitors are widely used in electronics, communications, machinery and other fields.

Are metal-insulator-metal type aluminium electrolytic capacitors a solid-state capacitor?

Recently, an innovative metal-insulator-metal type aluminium electrolytic capacitors (MIM-AECs) have been reported , which integrates the structure of MIM nanocapacitor with solid-state AECs.

Learn More

- Mauritius Super Aluminum Electrolytic Capacitor

- Rabat Super Electrolytic Capacitor

- Male Super Electrolytic Capacitor

- Super Electrolytic Capacitor

- Vietnam Super Smart Capacitor

- Super capacitor lightning protection solution for communication base stations

- Namibia s official super farad capacitor

- Port Moresby Super Capacitor Price

- Super Farad Capacitor in Osaka Japan

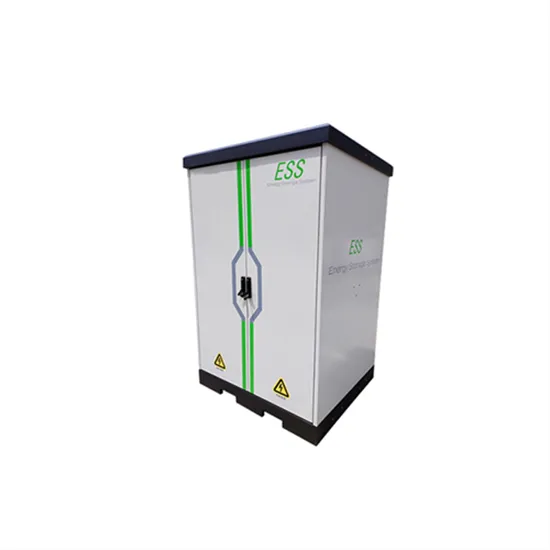

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.