Supercapacitor Technical Guide

Dec 14, 2020 · Supercapacitor Construction What makes'' supercapacitors different from other capacitors types are the electrodes used in these capacitors. Supercapacitors are based on a

SPEL | Railway Supercapacitor, High speed train, Module,

Oct 16, 2024 · SPEL | Railway Supercapacitor, High speed train, Module, Metro, Train, Support, Lithium Ion Battery, Graphene, Supercapacitors, super capacitors, Ultracapacitors, EDLC,

Nichicon Electrolytic Capacitors | HIFICollective

Nichicon Electrolytic CapacitorsNichicon manufacture electrolytic capacitors specifically designed for audio. We now stock the KZ, FW, ES, GB.DB, FG, HZ, KA, KX, VY and SW type. With

Supercapacitor Technical Guide

Dec 14, 2020 · Supercapacitors are ideal for applications ranging from wind turbines and mass transit, to hybrid cars, consumer electronics and industrial equipment. Available in a wide

Supercapacitor | Capacitor Types | Capacitor

2 days ago · The construction of supercapacitor is similar to the construction of electrolytic capacitors in that they consist of two foil electrodes, an electrolyte

Super Capacitors | SpringerLink

Jan 1, 2014 · Super capacitors, which are also called electrochemical capacitors or ultra capacitors, have far more capacity than conventional capacitors. For example, electrical

6 FAQs about [Male Super Electrolytic Capacitor]

What is the difference between a supercapacitor and an electrolyte?

In comparison, supercapacitors utilize a unique construction consisting of porous electrodes and an electrolyte to form an electric double layer. This design significantly increases the surface area for charge accumulation, enabling supercapacitors to store and release energy rapidly.

What is a supercapacitor EC?

Classification and properties of supercapacitor Supercapacitor is one type of ECs, which belongs to common electrochemical energy storage devices. According to the different principles of energy storage,Supercapacitors are of three types , , , , .

What is the difference between a capacitor and a supercapacitor?

Conventional capacitors store energy through the separation of static charges on their electrodes. In comparison, supercapacitors utilize a unique construction consisting of porous electrodes and an electrolyte to form an electric double layer.

What are supercapacitors & EDLC?

Supercapacitors also known ultracapacitors and electric double layer capacitors (EDLC) are capacitors with capacitance values greater than any other capacitor type available today. Supercapacitors are breakthrough energy storage and delivery devices that offer millions of times more capacitance than traditional capacitors.

Can solid polymer electrolytes be used in supercapacitors?

The application of solid polymer electrolytes in supercapacitors has so far been limited . Modern electrolytes require higher stability and mobility to operate in the high potential window. Gel electrolyte allows the combination of water, organic and ionic liquids, depending on the requirements of supercapacitors.

What is the difference between a battery and a supercapacitor?

In comparison, a supercapacitor stores energy electrostatically. The unique design of supercapacitors allows for rapid charge and discharge cycles. While batteries typically offer higher energy density and longer-term storage, supercapacitors excel in delivering quick bursts of energy.

Learn More

- Mauritius Super Aluminum Electrolytic Capacitor

- Rabat Super Electrolytic Capacitor

- Super high temperature electrolytic capacitor processing factory

- Super Electrolytic Capacitor

- Namibia s official super farad capacitor

- Port Moresby Super Capacitor Price

- West Africa Super Lithium Capacitor

- Grenada Super Double Layer Capacitor Factory

- Taipei Communication Base Station Super Capacitor 6 25MWh

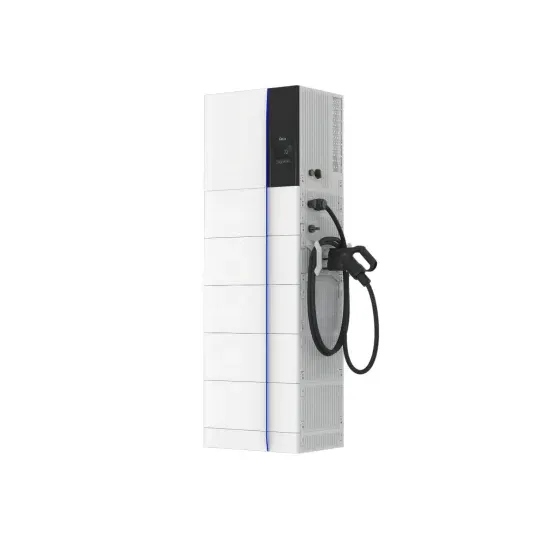

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.