19 Supercapacitor Manufacturers in 2025

Its product range has evolved from a single radial aluminum electrolytic capacitor into various products, including chip aluminum electrolytic capacitors, solid-state electrolytic capacitors,

High Temperature Electrolytic Capacitor Manufacturers

high temperature electrolytic capacitor manufacturers/supplier, China high temperature electrolytic capacitor manufacturer & factory list, find best price in Chinese high temperature electrolytic

High Temperature Electrolytic Capacitor Suppliers,

Alibaba offers 454 High Temperature Electrolytic Capacitor Suppliers, and High Temperature Electrolytic Capacitor Manufacturers, Distributors, Factories, Companies. There are 226 OEM,

A comprehensive review on supercapacitors: Their promise

May 15, 2024 · The performance of supercapacitors at elevated temperatures remains one of the obstacles against adopting supercapacitors. Hence, through the discussion of flexible and high

Chinese Aluminum electrolytic capacitors & Ultra-small electrolytic

Huakai Capacitor (Shenzhen) Co., Ltd. Main products: Aluminum electrolytic capacitors, Ultra-small electrolytic capacitors, Horn electrolytic capacitors, Horizontal electrolytic capacitor, High

High Temp Electrolytic Capacitors Aluminum

High Temp Electrolytic Capacitors Aluminum Electrolytic Capacitors are available at Mouser Electronics. Mouser offers inventory, pricing, & datasheets for High Temp Electrolytic

Wholesale Aluminum Electrolytic Capacitor Ultralow Temperature

May 21, 2025 · Looking for an ultralow temperature Aluminum Electrolytic Capacitor? Look no further! We are a leading China manufacturer, supplier, and factory offering high-quality

+ 125 C High Temp Electrolytic Capacitors Aluminum Electrolytic

+ 125 C High Temp Electrolytic Capacitors Aluminum Electrolytic Capacitors are available at Mouser Electronics. Mouser offers inventory, pricing, & datasheets for + 125 C High Temp

Best Custom Aluminum Electrolytic Capacitor Manufacturer

4 days ago · Capacitor manufacturers "Shenmao" with over 50 years of experience, high quality Aluminum Electrolytic Capacitors are widely used in the Industrial Automation

Professional Electrolytic Capacitor Manufacturer

The leader in leakage proof, high temperature and high voltage super capacitor technology The practitioner continuously optimizer electrolytic capacitors into miniaturized and low-impedance

Aluminum Electrolytic Capacitors Radial, High

Aug 19, 2025 · Fig. 9 - Typical multiplier of impedance at 100 kHz as a function of temperature (Z0 = Z at 20 °C) Fig. 6 - Typical multiplier of capacitance as a function of frequency at 20 °C (C0 =

A comprehensive review of supercapacitors: Properties,

Dec 15, 2022 · This power vs energy density graph is an illustration of the comparison of various power devices storage, where it is shown that supercapacitors occupy the region between

Supercapacitor Technical Guide

Feb 23, 2024 · Supercapacitors are breakthrough energy storage and delivery devices that offer millions of times more capacitance than traditional capacitors. They deliver rapid, reliable

Recommended processing factory for energy storage

Are electrolytic capacitors peer reviewed? Preprints and early-stage research may not have been peer reviewed yet. Due to their high specific volumetric capacitance,electrolytic capacitors are

Aluminum electrolytic capacitor factory, SMD electrolytic capacitor

Welcome to Pchicon, an industry aluminum electrolytic capacitor specialist in China! Till now we provided excellent stability, durability and utility aluminum electrolytic capacitor,SMD

Electrolytic capacitor technology from production to high

Jul 18, 2025 · Super electrolytic capacitors are used in energy storage systems to provide instantaneous large currents. MLCC and Electrolytic Capacitors optimize high-frequency

OEM High Temperature Electrolytic Capacitors

Apr 28, 2024 · Type Cylindrical Super Capacitor Brand Name OEM Supplier Type Original Manufacturer Characteristics high capacitance, low ESR, good consistency Capacitance 1

Capacitor Manufacturing Process | Dongguan Xuanxuan Electrolytic

Super Capacitor Manufacturing Process Xuansn pursues excellent engineering precision and quality standards to ensure that each supercapacitor reaches the highest level in terms of

Supercapacitors: Review of materials and fabrication methods

Nov 4, 2023 · FDK had examined lithium-ion (hybrid) capacitors by then [14]. By increasing the Ed and decreasing the anode potential when the cell voltage was high, carbon and Li-ion

6 FAQs about [Super high temperature electrolytic capacitor processing factory]

What is a super capacitor?

The supercapacitor is a new type of component that stores energy through the interface double layer formed between the electrode and the electrolyte. Beryl is a professional capacitor manufacturer with 18 years of R&D experience in electrolytic capacitors, super capacitors, and so on.

What is the maximum operating temperature of a solid electrolytic capacitor?

For decades the maximum recommended operating temperature of solid electrolytic capacitors was 125°C. Responding to needs in the automotive and downhole drilling industries passive component manufacturers developed surface mount tantalum capacitors rated at 150°C in 2002-2003.

Who is aluminum electrolytic capacitor manufacturer Shenmao?

Equipment hancing the yield rate; Continuously R&D investment from 1970 to ensure the pioneer in the capacitor field. Aluminum Electrolytic Capacitor Manufacturer Shenmao focused on producing snap-in capacitors, screw terminal capacitors, radial capacitor & SMD electrolytic. To be the global respected brand Aluminum Electrolytic

Which materials are used in solid electrolytic capacitors?

The primary challenges encountered when developing solid electrolytic capacitors with high temperature capabilities are associated with the carbon, silver and epoxy encapsulant materials used in conventional surface mount tantalum capacitors. Capacitor manufacturers have taken different paths to overcome these challenges.

Does silver migration cause leakage failures in solid electrolytic capacitors?

The results provide further strong evidence that silver migration is a potential cause of leakage failures in solid electrolytic capacitors during very high temperature unbiased life tests. The use of an electroplated metal layer provides other advantages to the reliability of a capacitor in a high temperature environment.

Is ESR stable in unencapsulated capacitors?

The use of carbon and silver formulations developed for high temperature applications resulted in ESR for unencapsulated capacitors that was stable at temperatures in excess of 200°C for 1000 hours or more. Although the ESR of the unencapsulated capacitors was stable, it was soon discovered that leakage was not.

Learn More

- Rabat Super Electrolytic Capacitor

- How much is the price of super capacitor factory

- Tehran Super Aluminum Electrolytic Capacitor

- High quality factory price 7 5 kw inverter for sale

- High quality blown circuit breaker factory for sale

- High quality rcb circuit breaker for sale Factory

- Namibia High Temperature Solar System

- High quality outdoor power station factory Factory

- High quality omega solar inverter in China Factory

Industrial & Commercial Energy Storage Market Growth

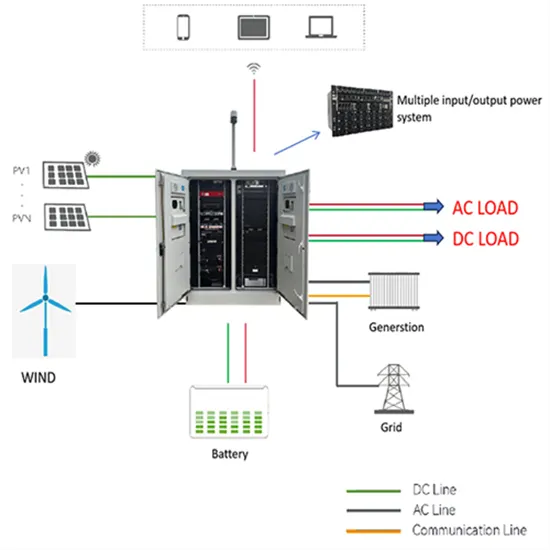

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

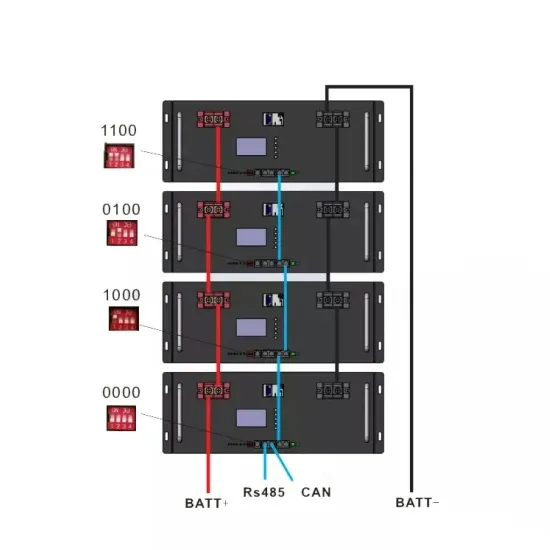

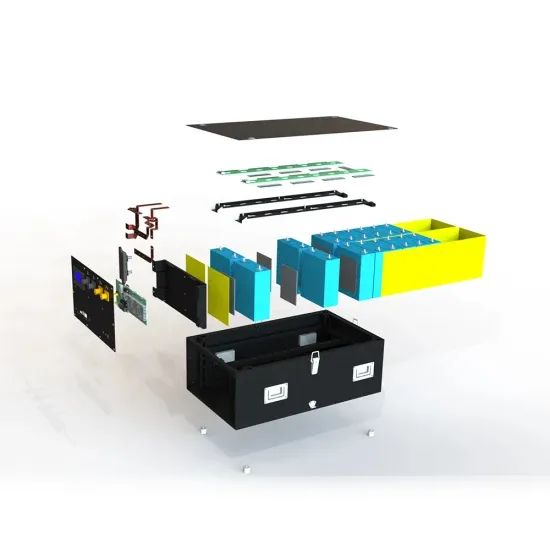

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.