Battery Cell Module Pack: Everything You Need

Sep 27, 2024 · To ensure the reliability and safety of the battery cell module pack, each prototype battery pack undergoes rigorous testing, such as performance

Understanding Li-Ion Battery Packs: A Complete Guide

Aug 8, 2024 · To start, let''s clarify what a Li-ion battery pack really is. Essentially, it''s a set of lithium-ion cells working together to provide a stable power source. Each cell is like a tiny

Smart Li Polymer Personalized Power Pack batteries

Experience smart Li-polymer battery packs with personalized and ruggedized designs. Reliable power for mobile devices with large innovative battery packaging solutions. Visit Today!

锂电池单体(cell)、电池组(Batteries)和电池包(pack

Jun 27, 2018 · 电池组(Batteries):由多个单体(cell)集合,构成一个单一的物理模块,提供更高的电压和容量(例如,一个电池模块,使用四个单体串联提供名义上的12V的电压,或者多

What Is A Lithium-Ion Battery Cell, Module, and

Jan 30, 2024 · What is a Lithium-ion Battery Pack? A lithium-ion battery pack is the largest and most complex assembly in the hierarchy of battery systems. It

Battery Manufacturer Tell You Everything About

May 29, 2024 · When packing a battery, multiple lithium-ion single-cell groups are connected in parallel and in series. Unlike a single cell, a battery pack requires

Battery Cell Module Pack: Everything You Need

Sep 27, 2024 · While the terms "battery cell," "battery module," and "battery pack" are often used interchangeably, the battery cell module pack refers to different

Analog | Embedded processing | Semiconductor company

The BQ2970 battery cell protection device ensures accurate monitoring and protection against overcurrent and overcharge conditions during high discharge or charge operations.

Lithium-ion batteries explained

Nov 2, 2020 · Lithium-ion batteries – also called Li-ion batteries - are used by millions of people every day. This article looks at what lithium-ion batteries are, gives an evaluation of their

Unlocking the Power: Distinguishing Battery

Dec 17, 2024 · - Voltage: Delivers a single unit of voltage (usually 3.7V for lithium-ion) Fun Fact: The AA battery you use in your remote control is actually just

Battery protectors

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

1S-24S Lithium Battery Pack Single Cell Measurement Series

Dec 23, 2021 · Midzooparts 1S-24S Lithium Battery Pack Single Cell Measurement Series String Voltage Measuring Instrument Identify Tester Li-ion Lifepo4: Amazon : ElectronicsTest

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · Despite the extensive research dedicated to optimizing the charging process for single cells, control strategies for packs remain unexplored. This paper focuses on the battery

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 11, 2024 · T he LN8231 monitors the voltage and current of a battery and protects it from being damaged due to overcharge voltage, over-discharge voltage, over-discharge current,

Battery configurations (series and parallel) and

Jun 26, 2023 · The weaker cell also discharges and charges first, which can cause problems like over-discharge and over-charge in the device. Single-cell

What Is A Lithium-Ion Battery Cell, Module, and

Jan 30, 2024 · We will delve into the components that make up a lithium-ion battery system, exploring the differences of battery cells, battery modules, and

A statistical distribution-based pack-integrated model

Jan 1, 2024 · The estimation of lithium battery pack is always an essential but troubling issue which has difficulty on considering the inconsistency during state estimation. Herein, an

TDS3BATC TEKTRONIX, Rechargeable Battery, Battery Pack, Single Cell

Buy TDS3BATC - TEKTRONIX - Rechargeable Battery, Battery Pack, Single Cell, Lithium Ion. Newark Electronics offers fast quotes, same day dispatch, fast delivery, wide inventory,

Lithium-Ion Information Guide | Houston, Texas USA

Lithium-Ion Information Guide - Technology ProfileBattery packs built to customer specifications using Lithium-Ion and Lithium-Polymer cells have been Designed and Developed at SWE for

6 FAQs about [Single-cell lithium battery pack]

How many cells are in a lithium-ion battery pack?

The method undergoes a real-world electric vehicle testing with 276 cells. The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous cells in parallel or series within the packs.

What is a lithium battery module pack?

Lithium batteries are an essential part of modern technology, powering everything from smartphones to electric vehicles. While the terms “battery cell,” “battery module,” and “battery pack” are often used interchangeably, the battery cell module pack refers to different stages of the battery’s construction.

What is a battery pack?

They may be configured in series, parallel or a mixture of both to deliver the desired voltage, capacity, or power density. Packs are identified by cell size, number of cells, battery structure, chemistry, chargeability, capacity, and voltage rating. Lithium-Ion Battery Products - Battery Packs are in stock at Digikey.

What are the specifications of a monomer cell and a battery pack?

Key specifications of both the monomer cell and the pack are detailed in Table 2. The total experimental setup depicted in Fig. 4 includes two testing protocols: single cell and battery pack performance tests. The system supports charge rate up to 3C, equating to 174 A for cell and 522 A for pack.

What is a battery cell module pack?

A battery cell module pack is the complete assembly, generally having many modules and several critical components: The pack production lines have to fulfill two functions: assembly and package.

What is the voltage of a lithium-ion battery cell?

The voltage of a lithium-ion battery cell is typically around 3.7 volts. The voltage of a lithium-ion cell is a crucial parameter as it influences the overall voltage of a battery pack when multiple cells are connected in series.

Learn More

- Class 9 lithium battery pack identification

- Lithium battery pack serial charging

- 12ah lithium battery pack

- Battery pack uses lithium battery

- 12V lithium battery pack

- Dushanbe professional lithium battery pack factory price

- 3 series and two parallel lithium battery pack

- What shock absorption is used for lithium battery pack

- Electric impact rammer lithium battery pack

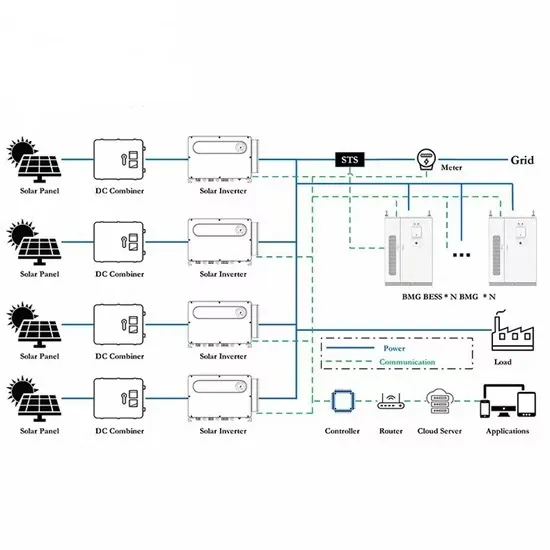

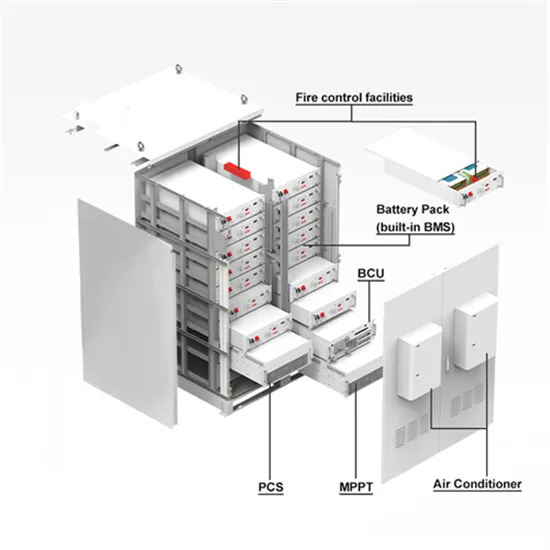

Industrial & Commercial Energy Storage Market Growth

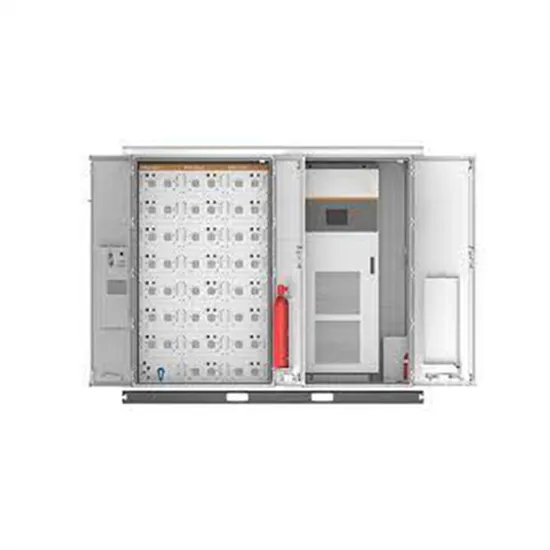

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.