Effects of reciprocating liquid flow battery thermal

Apr 3, 2020 · The effects of the reciprocation period, battery module coolant flow rate and ambient temperature on the temperature and the temperature imbalance of batteries were studied. The

Li-ion Battery Thermal Management – Air vs. Liquid Cooling

Based on the initial assessment for the Chevy Volt battery pack cooling, liquid-cooling has definite advantage compared to air-cooling in terms of heat transfer coefficient and cooling capacity. In

High-Voltage, Room-Temperature Liquid Metal Flow Battery

Jul 18, 2018 · Replacing the negative side with a liquid metal would yield a much higher voltage flow battery, benefiting energy density, power density, and efficiency. As a room-temperature

Thermal design and simulation of mini-channel cold

Jan 12, 2018 · ipal surface of the battery, and four K-type thermocouples were used to measure water inlet and outlet temperature. Computationally, the k-ε model in ANSYS Fluent was used

Pack-level modeling of a liquid cooling system for power batteries

Aug 15, 2022 · An efficient pack-level battery thermal management system is essential to ensure the safe driving experience of electric vehicles. In this work, we perform three-dimensional

Ionic liquid redox flow membraneless battery in microfluidic

Jan 1, 2023 · The proof-of-concept of a membraneless ionic liquid-based redox flow battery has been demonstrated with an open circuit potential of 0.64 V and with a density current ranging

A state-of-the-art review on modelling and simulation of battery

In contrast to any pure system, the hybrid PCM and liquid system can lower battery temperature; still, enabling fluid flow compromises temperature stability. The majority of researchers have

Thermal management of lithium-ion batteries with direct

Sep 1, 2024 · Therefore, the efficacy of the battery cooling part in managing generated heat is shown by a notable maximum temperature reduction of 30.709 % at the liquid flow (silicon oil)

Performance Analysis of the Liquid Cooling System for

Oct 30, 2023 · Even at a 4 C-rate discharge, the battery temperature can be kept below 35 °C at a flow rate of 5 mL/min below 30 °C when the flow rate exceeds 15 mL/min. Kim et al. [17]

Research progress on wide-temperature-range liquid

Dec 30, 2024 · The development of wide-temperature-range liquid electrolytes (WTLEs) for high-performance lithium-ion batteries (LIBs) will expand their multiple-scenario applications under

Influence of temperature on performance of all vanadium redox flow

Jun 14, 2018 · The main mass transfer processes of the ions in a vanadium redox flow battery and the temperature dependence of corresponding mass transfer properties of the ions were

Thermal management of flow batteries-

Dec 3, 2024 · Liquid flow batteries (RFBs) generate a lot of heat during operation. If the heat cannot be dissipated in a timely and effective manner, the battery temperature will rise, thus

Indirect liquid-cooled lithium-ion battery module with

1 day ago · Thus, while evaluating the heat transfer and hydrodynamic performance of minichannel cold plates integrated with the battery, it is imperative to carefully consider the

Thermal performance of a liquid-immersed battery thermal management

Feb 1, 2022 · In order to solve the problems of high temperature rise and large temperature difference of the battery pack, a novel liquid-immersed battery thermal

Thermal management for the 18650 lithium-ion battery

Dec 20, 2023 · To sum up, this work initially proved the excellent heat dissipation performance of the liquid immersion cooling system for battery thermal management, with a specific focus on

what are the advantages and disadvantages of liquid flow

An Introduction To Flow Batteries Flow Batteries. Lithium-ion batteries are one of many options, particularly for stationary storage systems. Flow batteries store energy in liquid electrolyte (an

Advancing Flow Batteries: High Energy Density

Dec 17, 2024 · A novel liquid metal flow battery using a gallium, indium, and zinc alloy (Ga 80 In 10 Zn 10, wt.%) is introduced in an alkaline electrolyte with an

Study on the Influence of Bus suspension Parameters on

Dec 6, 2024 · Liquid cooling systems in BTMS utilize coolants often water glycol mixtures to actively manage battery temperature through conduction and convection. These systems are

Flow battery – Knowledge and References – Taylor & Francis

Flow battery A flow battery is a type of rechargeable secondary battery that stores energy chemically in liquid electrolytes. Unlike conventional batteries, which have fixed electrodes and

Investigation on the temperature control performance and

Sep 1, 2023 · For ensuring the safety of lithium-ion batteries in application, keeping the temperature of the battery pack in the desired range is crucial under different operating

Effects of reciprocating liquid flow battery thermal

Apr 3, 2020 · The effects of the reciprocation period, battery module coolant flow rate and ambient temperature on the temperature and the temperature imbalance of batteries were studied. The

Effect of tube location on the temperature of plate lithium-ion battery

May 1, 2023 · Effect of tube location on the temperature of plate lithium-ion battery applicable in the aerospace industry in the presence of two-phase nanofluid flow inside a channel placed in

Flow battery activities at the University of Strathclyde

Jan 23, 2025 · Recent work involved development of StorTera''s lithium polysulphide Single Liquid Flow Battery (SLIQ) technology by refining the system design and improving the electrolyte

6 FAQs about [Liquid flow battery applicable temperature]

Do liquid cooling thermal management systems improve EV battery performance?

This paper has highlighted the crucial role of liquid cooling thermal management systems (BTMS) for electric vehicle (EV) batteries in enhancing their performance and ensuring safety. As EV adoption continues to rise, effective thermal management has become a key factor in maximizing battery efficiency, lifespan, and safety.

How to maintain the average temperature of a battery module?

Based on this, a cooling plate with six channels was applied to both the top and bottom parts, and the top and bottom cooling showed sufficient cooling performance in maintaining the average temperature of the battery module below 45 °C. 1. Introduction

Can liquid cooling improve battery efficiency?

Research indicates that liquid cooling systems can achieve better thermal regulation, improve battery efficiency, and extend the operational life of the battery by keeping the temperature within the optimal range. KEYWORDS: Electric vehicle,liquid cooling,battery cells, thermal management.

How hot does a battery module get?

The results showed that the average temperature of the battery module decreased from 53.8 °C to 50.7 °C when the flow rate in the cooling plate increased from 2 to 6 L/min, but that the pumping power increased from 0.04 to 0.81 W due to the higher pressure drop.

What factors affect the temperature control of a battery?

In addition, an increase in the width of the cooling channel and number of channels resulted in a decrease in the average temperature of the battery module and a reduction in the pumping power. The most influential variable for the temperature control of the battery was an increase in the flow rate.

How does a higher flow rate affect battery cooling capacity?

The pumping power increased 22 times when the flow rate rose from 2 to 6 L/min, although the battery temperature drop was just 3.1 °C. Raising the pump power for cooling in an electric vehicle can reduce the driving range due to increased electric power consumption. Despite a higher flow rate, battery cooling capability has a limit.

Learn More

- Zinc-based liquid flow battery price analysis

- Target enterprises of all-vanadium liquid flow battery

- Riyadh All-vanadium Liquid Flow Battery Pump

- Iron-based liquid flow battery energy storage system

- Liquid flow battery stack

- Civilian vanadium liquid flow battery

- Average voltage of all-vanadium liquid flow battery

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Vientiane All-vanadium Liquid Flow Battery Environment

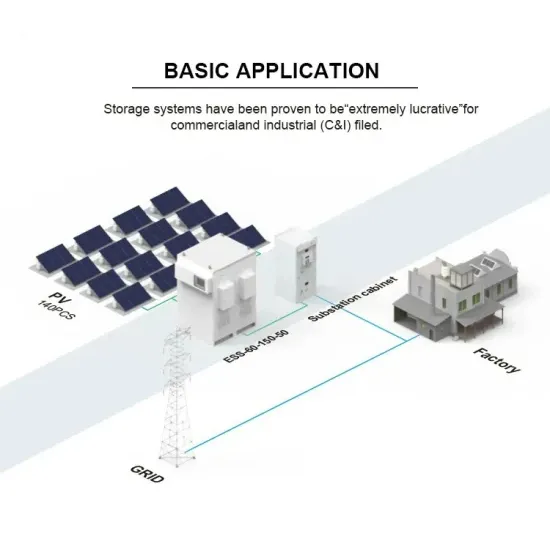

Industrial & Commercial Energy Storage Market Growth

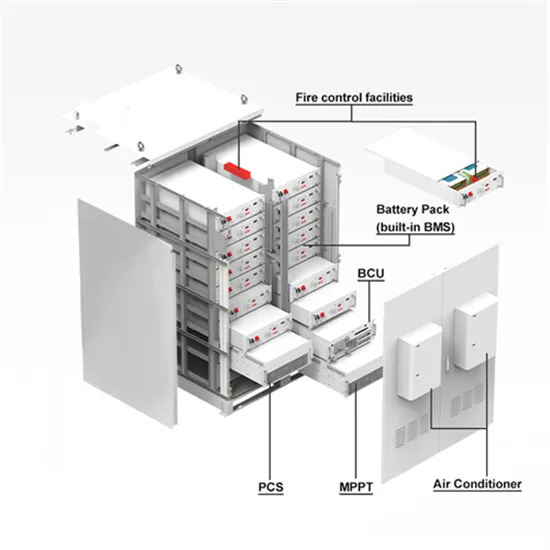

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

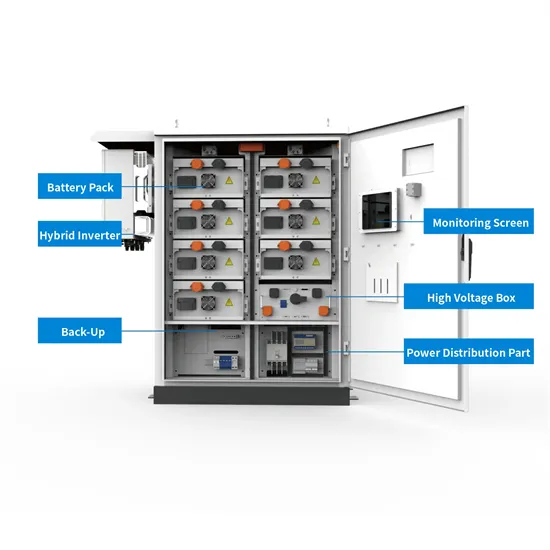

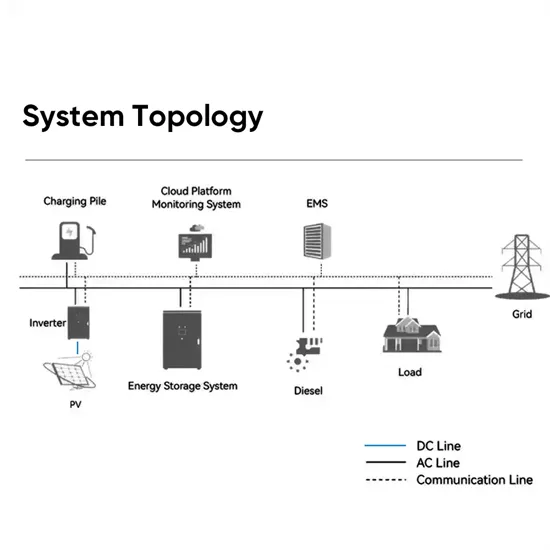

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.