Effect of tilt angle on the performance and electrical parameters

Jul 1, 2022 · Therefore, the present article aims to investigate the effect of varying module tilt angle on the PV cell temperature and its electrical parameters at the laboratory environment

Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV

Jan 1, 2013 · In this paper, a brief discussion is presented regarding the operating temperature of one-sun commercial grade silicon- based solar cells/modules and its effect upon the electrical

Photovoltaic (PV) Cell: Characteristics and Parameters

Apr 3, 2025 · NREL scientists study the long-term performance, reliability, and failures of photovoltaic (PV) components and systems in-house and via external collaborations. Through

An Overview of Factors Influencing Solar Power Efficiency

Nov 29, 2021 · Solar energy is becoming more intense for both generating electricity and reducing greenhouse gas emissions. The photovoltaic effect is used in solar photovoltaic (PV) cells to

Advanced polymer encapsulates for photovoltaic devices −

Sep 1, 2021 · During the long time operation at outdoor conditions, PV cells experience significant morphological and structural changes, optical absorption decay, and impairment of the

Photovoltaic solar cell technologies: analysing the state of

Mar 28, 2019 · Here, we critically compare the different types of photovoltaic technologies, analyse the performance of the different cells and appraise possibilities for future technological

Setting the Bar for Device Performance of Photovoltaic

Jun 2, 2025 · The Challenges High-accuracy, certified calibrations of PV device performance are crucial for PV researchers, manufacturers, and end users. PV module manufacturers and PV

Optimal parameters estimation and modelling of

Oct 30, 2018 · This paper introduces a proposed approach to estimate the optimal parameters of the photovoltaic (PV) modules using in-field outdoor measurements and manufacturers''

PV Performance Modeling Methods and Practices

Apr 15, 2020 · The operating temperature of PV modules and the cells inside the modules affects the perfor-mance of the PV system. Typical PV cells lose efficiency as temperatures rises.

Defect analysis and performance evaluation of photovoltaic modules

Jan 8, 2025 · A defect analysis and performance evaluation of photovoltaic modules using quantitative electroluminescence imaging is carried out on three common photovol

Solar photovoltaic modeling and simulation: As a renewable

Nov 1, 2018 · Moreover, the performance of PV module for real metrological data (irradiance and temperature) shows good results. In addition to this, it is presumed as a sturdy tool to evaluate

Mechanical performance analysis of the lightweight semi

3 days ago · The mechanical performance of a lightweight photovoltaic (PV) module plays a more central role than that of a conventional PV module because it is more prone to causing

Performance of Photovoltaic Modules of Different Solar Cells

In this paper, an attempt of performance evaluation of semitransparent and opaque photovoltaic (PV) modules of different generation solar cells, having the maximum efficiencies reported in

Defect analysis and performance evaluation of photovoltaic modules

Jan 8, 2025 · Abstract This paper presents a defect analysis and performance evaluation of photovoltaic (PV) modules using quantitative electroluminescence imaging (EL). The study

Effect of Temperature on the Performance of

Sep 27, 2020 · Effect Of Temperature On The Performance Of Photovoltaic Module Like all other semiconductor devices, solar cells are sensitive to temperature. Increase in temperature

6 FAQs about [Photovoltaic cell module performance]

What are the characteristics and performance parameters of photovoltaic (PV) cells?

Understanding the key characteristics and performance parameters of photovoltaic (PV) cells—such as the current-voltage (I-V) behavior, maximum power point (MPP), fill factor, and energy conversion efficiency—is essential for optimizing solar energy systems.

What parameters define the performance of PV modules?

There are parameters that define the performance of PV modules. These usually differ from module to module depending on various factors such as the material used to make the cells, the number of cells in a module etc.

How does climate affect the performance of photovoltaic (PV) modules?

The long-term performance of photovoltaic (PV) modules declines over time, influenced by environmental conditions such as temperature, humidity, and shading, which pose operational challenges. Quantifying this long-term degradation is crucial for predicting the return on investment of PV systems.

Do photovoltaic modules have a defect analysis and performance evaluation?

This paper presents a defect analysis and performance evaluation of photovoltaic (PV) modules using quantitative electroluminescence imaging (EL). The study analyzed three common PV technologies: thin-film, monocrystalline silicon, and polycrystalline silicon.

How the different factors affect the performance of PV cells and modules?

We shall now see how the different factors affect the performance of PV cells and modules. Since PV cells and modules are made up on semiconductor materials, there is bound to be some sort of resistance in the circuit. The resistance at the Maximum Power Point of the Solar Cell is called the Characteristic Resistance (RCH):

What is the relationship between PV modules and electrical performance?

The various correlations proposed in the literature represent simplified working equations which can be apply to PV modules or PV arrays mounted on free-standing frames, PV-Thermal collectors, and building integrated photovoltaic arrays, respectively. The electrical performance is primarily influenced by the material of PV used.

Learn More

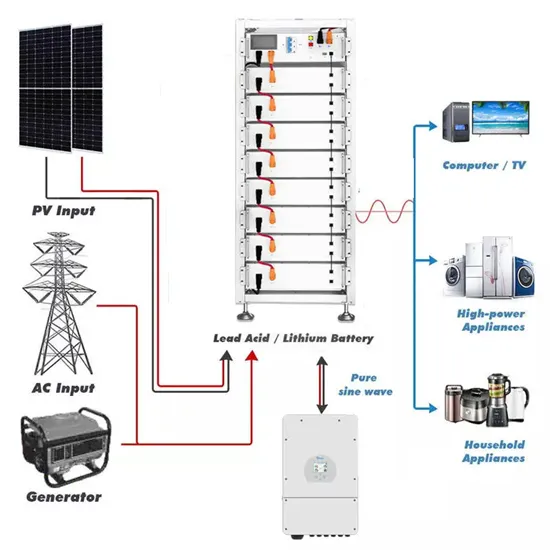

- Photovoltaic cell module auxiliary equipment

- Photovoltaic cell silicon wafers and module silicon wafers

- Abu Dhabi Solar Photovoltaic Module Company

- Seamless installation of photovoltaic module prices

- Which thin-film photovoltaic module manufacturer is better in Singapore

- Photovoltaic module container manufacturers

- Morocco Photovoltaic Module Project

- Photovoltaic module project return visit

- Thin-film photovoltaic module cost

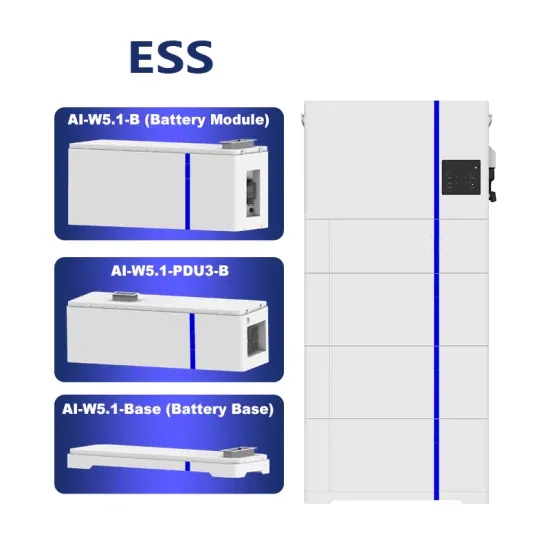

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.