Flexible Solar Panels — The Ultimate Guide

So, what are flexible PV panels, how are they used, and do the benefits outweigh the disadvantages? Here''s the ultimate guide to everything you need to know about flexible solar

Flexible Solar Panels vs. Rigid Solar Panels:

May 7, 2024 · The optimal photovoltaic panel solution depends heavily on the specifics of your property, roofscape, climate, and budget. For installations on

Advantages and Limitations of Flexible Solar Panels –

Mar 12, 2025 · Flexible solar panels can perform relatively well in cloudy or low-light conditions compared to some traditional panels. This makes them a good choice for areas that don''t

Flexible Solar Panels: Pros, Cons, and Complete

Jun 20, 2025 · Explore the complete guide to flexible solar panels including pros, cons, applications, and expert installation tips. Ideal for RVs, boats, and off

Overview of the Current State of Flexible Solar Panels and Photovoltaic

Aug 25, 2023 · In this regard, this particular review paper seeks to provide a comprehensive and up-to-date examination of the current state of flexible solar panels and photovoltaic materials.

Advantages and disadvantages of flexible photovoltaic

A photovoltaic plant has several advantages and disadvantages. Among the disadvantages of solar panels is their dependence on sunlight. Indeed, the intensity of the sun varies throughout

Advantages and disadvantages of flexible photovoltaic

materials and energy consum n-film flexible solar panels and crystalline silicon flexible panels. While most flexible photovoltaic panel kits already come with inverters, lithium batteries, power

Flexible PV Module: Advantages, Disadvantages, and More

Jan 16, 2024 · Whether it''s an unconventional roof shape or a non-traditional application like vehicles or marine installations, flexible PV modules provide a contrasting alternative to

Flexible Solar Panels in the UK (August 2025 Guide)

Oct 31, 2024 · Unlike the conventional solar panels, flexible solar panels are made by layering one or more thin films of photovoltaic (PV) material on an

What Are Flexible Solar Panels? The Lightweight

Jul 19, 2022 · The clear distinction between those two types of solar panels is thickness. In thin-film solar panels, the layers of photovoltaic materials are

The Truth About Flexible Solar Panels: Pros, Cons

Dec 18, 2024 · Despite the numerous advantages of flexible solar panels, they do have some drawbacks compared to traditional rigid panels. One of the main

Advantages of Flexible Solar Panels: Benefits, Efficiency

Jan 6, 2025 · Explore the advantages of flexible solar panels: lightweight, portable, durable, and versatile for curved surfaces. Perfect for any setup!

Flexible Solar Panel Advantage And Disadvantages

Jan 14, 2021 · The deposition of silicon crystals with photovoltaic properties on a flexible base eliminated the main disadvantage of solar cells – fragility The

Photovoltaic technologies for flexible solar cells: beyond silicon

Mar 1, 2021 · For the previous few decades, the photovoltaic (PV) market was dominated by silicon-based solar cells. However, it will transition to PV technology based on flexible solar

6 FAQs about [Disadvantages of flexible photovoltaic panels]

What are the disadvantages of flexible solar panels?

Efficiency: The main disadvantage of flexible solar panels is they are much less effective at generating electricity from solar energy than traditional panels. The reason for the decreased efficiency is the thin designs provide less conducting material compared to regular monocrystalline and polycrystalline panels.

Are flexible solar panels better than rigid solar panels?

Despite the numerous advantages of flexible solar panels, they do have some drawbacks compared to traditional rigid panels. One of the main disadvantages is their lower efficiency. Due to the nature of the flexible materials used, these panels typically have a lower power output per square foot than crystalline panels.

Why are flexible solar panels less efficient?

The reason for the decreased efficiency is the thin designs provide less conducting material compared to regular monocrystalline and polycrystalline panels. As a result, most flexible solar panels are designed for low-wattage power needs of 50 to 300 watts.

Are flexible solar panels the future of photovoltaics?

As advancements in materials and manufacturing processes continue, the potential for flexible solar panels to play a significant role in the future of photovoltaics remains promising.

Why are flexible solar panels so expensive?

Currently, flexible solar panels also tend to have higher costs compared to their rigid counterparts. The specialized manufacturing processes and materials used in producing these panels contribute to their elevated price point.

Are flexible solar panels safe?

Hail, strong winds, temperature fluctuations, and other harsh weather conditions pose minimal threats to flexible panels, ensuring a more extended and reliable lifespan. The technology behind flexible solar panels, known as thin-film technology, is a game-changer in the world of solar power generation.

Learn More

- Advantages and disadvantages of flexible photovoltaic solar panels

- Flexible solar panels photovoltaic panels

- Disadvantages of installing Huawei photovoltaic panels on roofs

- Flexible monocrystalline silicon photovoltaic panels

- What are the specifications of flexible photovoltaic panels

- Flexible monocrystalline silicon solar photovoltaic panels

- Flexible photovoltaic panels connected to family car batteries

- Do photovoltaic panels need batteries installed

- BESS price of photovoltaic panels for villas in Cambodia

Industrial & Commercial Energy Storage Market Growth

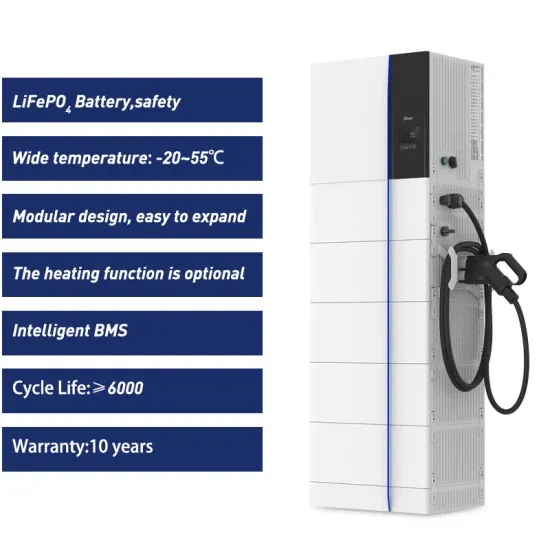

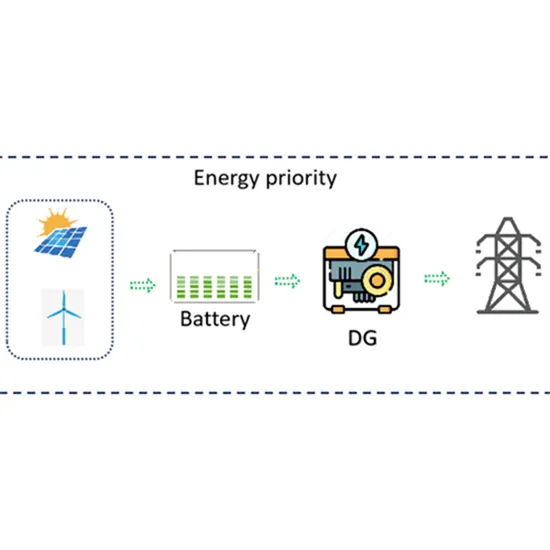

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.