Battery Cells vs. Modules vs. Packs: How to Tell the Difference

5 days ago · Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs

How to Distinguish Battery Cells, Battery Modules, and Battery

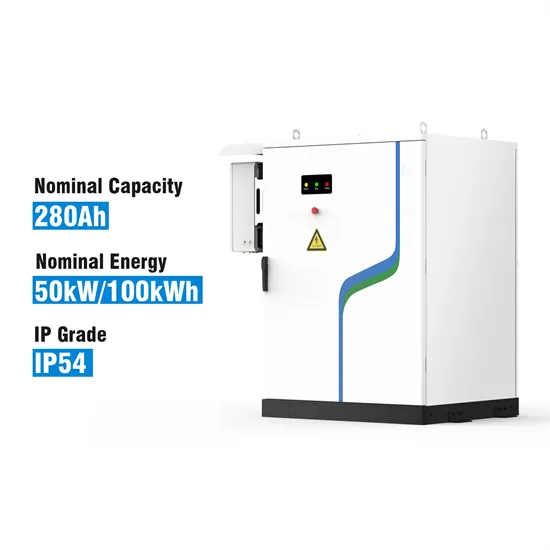

Components: A battery pack includes multiple battery modules, the necessary electrical connections, a BMS for overall pack management, and sometimes cooling systems.

[电池扫盲]一文带小白了解电芯(cell),电池模块 (module

Jun 18, 2023 · 今天小编带大家了解一下动力电池最重要的三个组成部分,即电芯(cell),电池模块 (module)以及电池包(pack) 电芯是构成动力电池的基本单元,一般是锂离子电池。 当

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what

Difference between Battery Module And Battery

Oct 12, 2022 · In general, a battery module is a collection of individual batteries that are connected together to form a larger unit, while a battery pack is a

Introduction to Electric Vehicle Battery Modules and Packs

4 days ago · Modules are then assembled to form the EV battery pack, which is the final deployable battery system. The modules are also assembled in specific configurations to

Battery Cell, Module, or Pack: What''s the difference?

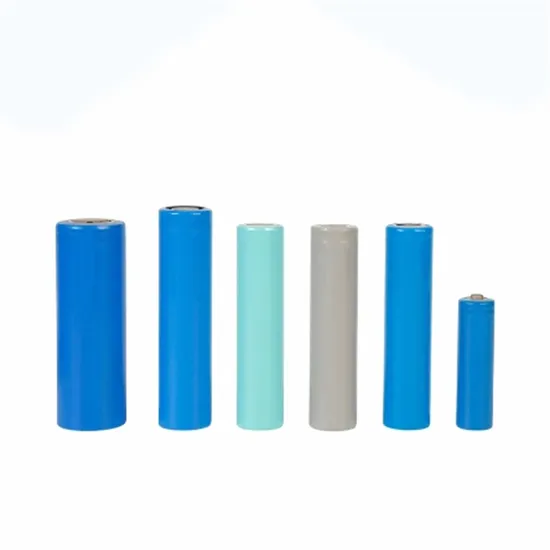

Each component serves a unique role: battery cells are the individual units that store energy, modules are groups of cells connected together, and packs are assemblies of modules that

Battery Cell VS Battery Module VS Battery Pack

Mar 5, 2024 · Knowing the nuances of battery technology is essential for effective content optimization. This article will delve into the basics of the differences

What Is Battery Module?

Apr 1, 2025 · A battery module is a compact, integrated unit that houses multiple battery cells and their management system, designed to deliver power in a safe and efficient manner. These

电池单元与电池模块与电池组:您需要了解的一切

Oct 16, 2024 · 如果您从事电动汽车和可再生能源等行业,了解电池单元、电池模块和电池组之间的区别非常重要。这些部件在电池系统中发挥着不同的作用,

What Is A Lithium-Ion Battery Cell, Module, and

Jan 30, 2024 · What is a Lithium-ion Battery Module? A lithium-ion battery module is a group of interconnected battery cells that work together to provide a

晖耀激光告诉你—电池模组与pack的区别是什么?

Nov 20, 2023 · 1、电池模组的定义与组成(Battery Module) 电池模组是电池系统的基本构建单元,通常由多个电池单体组成。 电池单体是电池的基本单元,通过串联或并联的方式连接在一

Battery Module vs Pack: Differences for Energy

Dec 29, 2023 · Delve into the distinctions between battery modules and packs. Gain insights into performance metrics and considerations for efficient energy

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

5 days ago · What Is a Battery Pack? A battery pack integrates multiple modules and adds the systems that make the entire solution reliable: high-level BMS, power distribution, protection,

What Are Battery Cells, Battery Modules, And

Feb 23, 2024 · Battery cell technology is the cornerstone of battery systems. The process of assembling lithium battery cells into groups is called PACK, which

Battery Cell Module Pack: Everything You Need

Sep 27, 2024 · To ensure the reliability and safety of the battery cell module pack, each prototype battery pack undergoes rigorous testing, such as performance

Battery Cell Module Pack: Everything You Need

Sep 27, 2024 · While the terms "battery cell," "battery module," and "battery pack" are often used interchangeably, the battery cell module pack refers to different

储能系统基础概念解析-CSDN博客

May 31, 2023 · 1、基础名词、概念、对应的英文单词、系统组成 电池储能系统(Battery Energy Storage System, BESS); 电芯(Battery Cell):单个电

锂电池单体(cell)、电池组(Batteries)和电池包(pack

Jun 27, 2018 · 没有接触过锂电池的很多朋友,一般会把电池厂家生产好了的电池包(pack)当成是一块大电池,实际上,我们用的锂电池其实也跟铅酸电池一样,也是由一块一块的单体电池

Sturcture of Battery: From Cell to Module and

Apr 21, 2025 · The Structure of a Battery To review a battery''s structure from a macro-view as a whole pack until the smallest units, which are referred to as

Learn More

- Tanzania battery module pack

- Pack battery module

- Do you have a 14 volt lithium battery pack

- Lima lithium battery pack temperature protection point

- Maintenance of lithium battery pack

- Lithium battery pack internal parallel connection

- Protection level of energy storage battery PACK

- South Sudan lithium battery PACK

- Huawei battery box pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.