Design and Sizing of Solar Photovoltaic Systems

Mar 15, 2023 · In addition to the PV modules, battery, inverter and charge controller there are other components required in a solar PV microgrid system; these components are referred to

Solar PV systems design and monitoring

Jan 1, 2020 · A solar photovoltaic (PV) system includes the main components of PV modules, a solar inverter, and a bias of system (BoS), which can generate AC and DC power. However,

HYBRID POWER SYSTEMS (PV AND FUELLED

Aug 1, 2019 · Part 1 section 10 of the Off-grid PV Power System Design Guideline details how to select the dc system battery voltage however with many of the larger hybrid systems the

Photovoltaic inverter design

A solar inverter converts the variable direct current (DC) output of a photovoltaic (PV) panel into alternating current (AC) that can be fed into a commercial electrical grid or used by a local, off

PV Inverter Design Using Solar Explorer Kit (Rev. A)

Apr 1, 2023 · ABSTRACT This application report goes over the solar explorer kit hardware and explains control design of Photo Voltaic (PV) inverter using the kit. Contents

How to Design a Solar PV System: A Comprehensive Guide

Designing a solar photovoltaic (PV) system can be a rewarding endeavor, both environmentally and financially. As the demand for renewable energy sources rises, so does the interest in

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · Furthermore, various inverter topologies based on their design, classification of PV system, and the configuration of grid-connected PV inverters are discussed, described and

GRID CONNECTED PV SYSTEMS WITH BATTERY ENERGY

May 22, 2023 · Note: PV battery grid connect inverters and battery grid connect inverters are generally not provided to suit 12V battery systems. 48V is probably the most common but

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · Abstract: With a plethora of inverter station solutions in the market, inverter manufacturers are increasingly supplying the consumer with nished integrated products, often

GRID-CONNECTED PV SYSTEMS

Aug 19, 2019 · To design systems where the output voltages of the array do not fall outside the range of the inverter''s dc operating voltages and maximum input voltage, the historical

Photovoltaics: Basic Design Principles and Components

Oct 14, 2013 · Photovoltaics: Basic Design Principles and Components If you are thinking of generating your own electricity, you should consider a photovoltaic (PV) system—a way to gen

Optimal design of grid-connected photovoltaic system using

Nov 1, 2022 · Grid-connected photovoltaic systems have been widely utilized as means of renewable energy-based electricity supply worldwide. Nevertheless, one of the major issues in

Photovoltaic Systems with Module-Level Power Electronics

Sep 18, 2015 · Direct current (DC) power optimizers and microinverters (together known as module-level power electronics, or MLPE) are one of the fastest growing market segments in

Designing the Perfect Solar Inverter: A Comprehensive Guide

Jan 8, 2023 · Learn about the components, features and benefits of a successful solar inverter system, as well as tips for creating an efficient, cost-effective energy solution.

SolarEdge System Design and the NEC

Nov 30, 2022 · SolarEdge Three Phase Inverter System Design and the National Electrical Code Introduction The SolarEdge Distributed Energy Harvesting System is a state-of-the-art system

SOLAR PV SYSTEM DESIGN

Apr 8, 2021 · The total energy requirement of the system (total load) i.e Total connected load to PV panel system = No. of units × rating of equipment = 2 × 18 + 2 × 60 = 156 watts Total watt

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · In this paper global energy status of the PV market, classification of the PV system i.e. standalone and grid-connected topologies, configurations of grid-connected PV inverters,

Design and Evaluation of a Photovoltaic Inverter with

Mar 21, 2020 · This thesis investigates the control of variable-frequency sources as conventional syn-chronous machines and provides a detailed design procedure of this control structure for

HANDBOOK ON DESIGN, OPERATION AND

May 29, 2024 · The major components of a PV system include PV modules, inverters, power optimisers, surge arresters, isolation transformers, batteries, battery charge controllers,

A comprehensive review of grid-connected solar photovoltaic system

Jun 1, 2023 · The different solar PV configurations, international/ national standards and grid codes for grid connected solar PV systems have been highlighted. The state-of-the-art

Critical review on various inverter topologies for

Feb 22, 2021 · To achieve optimum performance from PV systems for different applications especially in interfacing the utility to renewable energy sources,

6 FAQs about [Inverter Photovoltaic System Design]

What is an inverter in a solar PV power plant?

1. Understanding the Role of an Inverter in a Solar PV Power Plant In a solar PV power plant, the inverter is the critical component that converts the direct current (DC) produced by the solar panels into alternating current (AC), which is compatible with the grid and can be used by end consumers.

How do you design a solar inverter?

The design of the inverter must account for several factors, including the type of solar panels used, the plant's total capacity, grid requirements, and operational efficiency. Consider a 32 MW (AC) grid-tied solar PV power plant. The plant consists of multiple solar arrays, each producing DC power.

How to control a PV inverter?

As shown earlier, the PV inverter control requires two real-time ISR’s: one is for the closed loop control of the DC-DC stage and the other for the closed loop control of the DC-AC stage. The C2000 Solar Explorer Kit project makes use of the “C-background/C-ISR/ASM-ISR” framework.

Why do we need a solar inverter?

The use of solar PV is growing exponentially due to its clean, pollution-free, abundant, and inexhaustible nature. In grid-connected PV systems, significant attention is required in the design and operation of the inverter to achieve high efficiency for diverse power structures.

How photovoltaic (PV) is used in distributed generation system?

The application of Photovoltaic (PV) in the distributed generation system is acquiring more consideration with the developments in power electronics technology and global environmental concerns. Solar PV is playing a key role in consuming the solar energy for the generation of electric power.

What is a power electronic based inverter?

In both standalone or grid-connected PV systems, power electronic based inverter is the main component that converts the DC power to AC power, delivering in this way the power to the AC loads or electrical grid.

Learn More

- Vietnam photovoltaic energy storage inverter design

- Small photovoltaic inverter design

- Design of grid-connected photovoltaic generator set for communication base station inverter

- Design of home photovoltaic grid-connected inverter

- Photovoltaic inverter retail

- Which is the best photovoltaic power station inverter

- Lilongwe EK Photovoltaic Power Inverter

- 18 kW photovoltaic inverter

- Photovoltaic inverter blocking wave timing

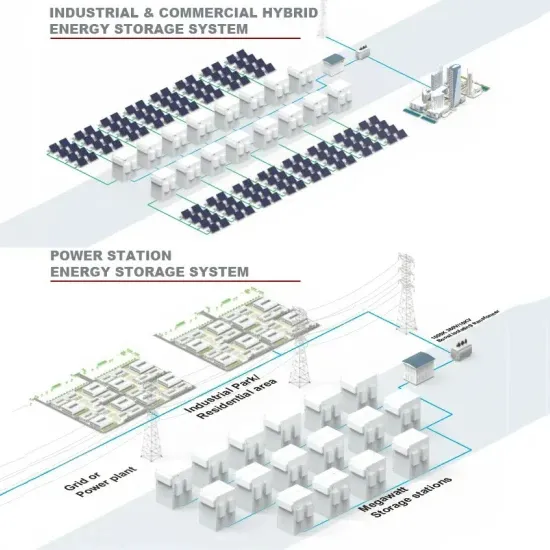

Industrial & Commercial Energy Storage Market Growth

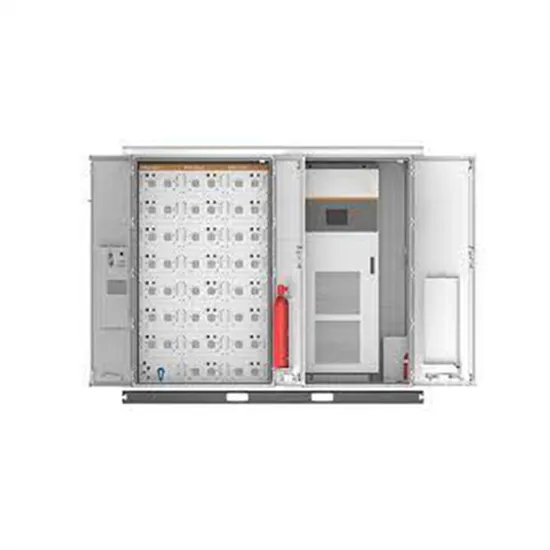

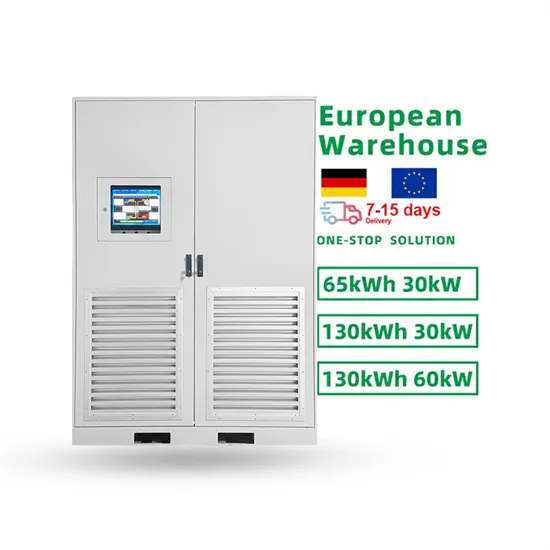

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

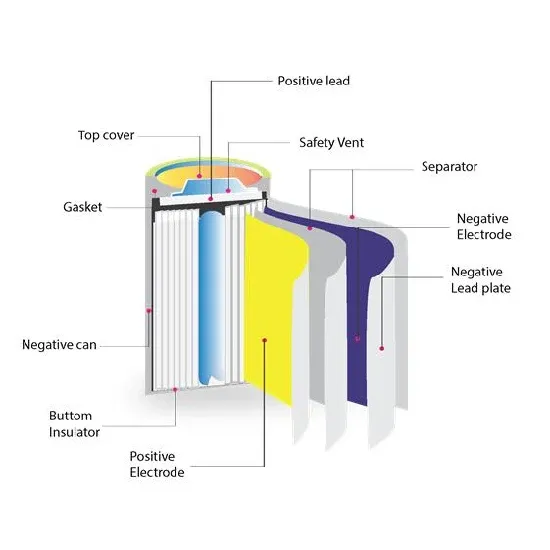

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.