Design of small independent photovoltaic power generation

Sep 1, 2024 · This article designs a small independent photovoltaic power generation system, which includes solar panels, controllers, batteries, and inverter modules. The design

Micro photovoltaic grid-connected inverter design

The Solar Microinverter Reference Design is a single stage, grid-connected, solar PV microinverter. This means that the DC power from the solar panel is converted the efficiency

DESIGN OF PUSH PULL MICRO INVERTER FOR SMALL

Mar 26, 2018 · Majority of our existing electrical devices are designed and operates on alternating current (AC) supply systems, and that is why design and development of dc-ac converters with

Design and analysis of soft-switching and small-signal model

Jul 1, 2024 · The phenomenon of global climate change needs a gradual transition in the composition of energy sources towards those that have low or zero carbon emissions [[1], [2],

PV Inverter Design Using Solar Explorer Kit (Rev. A)

Apr 1, 2023 · The solar explorer kit, TMDSSOLAR(P/C)EXPKIT, (see Figure 1) provides a flexible and low voltage platform to evaluate the C2000TM microcontroller family of devices for a

PV Inverter Design Using Solar Explorer Kit (Rev. A)

Apr 1, 2023 · ABSTRACT This application report goes over the solar explorer kit hardware and explains control design of Photo Voltaic (PV) inverter using the kit.

Customized design of microinverter based solar photovoltaic

Sep 1, 2022 · The proposed affordable solution offers many advantages over the traditional central inverters. It provides more output power as compared to traditional central inverters

Design and Sizing of Solar Photovoltaic Systems

Feb 2, 2022 · The 6-hour course covers fundamental principles behind working of a solar PV system, use of different components in a system, methodology of sizing these components

HYBRID POWER SYSTEMS (PV AND FUELLED

Aug 1, 2019 · This guideline has one section for sizing the components of a hybrid system where the fuelled generator is being used as a backup to provide power when there is insufficient

Design and Feasibility Studies of a Small Scale Grid Connected Solar PV

Dec 1, 2016 · In the present work it is tried to develop a small scale grid connected solar photovoltaic (SPV) system. The details of the grid connected solar photovoltaic system are

An Overview of Microinverter Design Characteristics and

Aug 11, 2021 · Abstract - Micro-inverter technologies are becoming increasingly popular as a choice of grid connection for small-scale photovoltaic systems. Efficiently harvesting the

A Small Photovoltaic Inverter Design Based on STM32

A small photovoltaic (PV) inverter design with a 500W output power rating that is based on an STM32 micro-controller together with soft-switching is proposed in this study. Aiming at the

An Introduction to Inverters for Photovoltaic

Jun 3, 2020 · An Introduction to Inverters for Photovoltaic (PV) Applications This article introduces the architecture and types of inverters used in photovoltaic

Digitally Controlled Solar Micro Inverter Using C2000

Jun 9, 2017 · A 250-W isolated micro inverter design presents all the necessary PV inverter functions using the Piccolo-B (F28035) control card. This document describes the power

Design and Implementation of a Micro-Inverter for

Mar 21, 2020 · Date: .. ABSTRACT The objective of this work is to design and build a novel topology of a micro-inverter to directly convert DC power from a

Design of small independent photovoltaic power generation

Sep 1, 2024 · This article designs a small independent photovoltaic power generation system, which includes solar panels, controllers, batteries, and inverter modules.

TI 10KW High efficient/small size solar inverter new

Jun 27, 2018 · Platform for testing both 2-level and 3-level inverter by enabling or disabling middle devices through digital control. 70 ns (max) Prop Delay. 3V to 15V input supply range. Thanks!

Design of Small Photovoltaic (PV) Solar-Powered Water

May 6, 2019 · To design a solar-powered water pump system for this design example, which consists of a mid-size organic sheep operation in Cottage Grove, Oregon, it is necessary to

A Small Photovoltaic Inverter Design Based on STM32

Sep 5, 2021 · A small photovoltaic (PV) inverter design with a 500W output power rating that is based on an STM32 micro-controller together with soft-switching is proposed in

A Small Photovoltaic Inverter Design Based on STM32

Sep 5, 2021 · A small photovoltaic (PV) inverter design with a 500W output power rating that is based on an STM32 micro-controller together with soft-switching is proposed in this study.

Grid Connected Inverter Reference Design (Rev. D)

May 11, 2022 · High-efficiency, low THD, and intuitive software make this design attractive for engineers working on an inverter design for UPS and alternative energy applications such as

Solar Photovoltaic Projects

Feb 9, 2024 · Photovoltaic (PV) solar electricity systems have captured a lot of interest as the system components have grown more mature, capable, and reliable. The references and

Research and design of a dual buck micro grid-connected inverter

Apr 1, 2025 · Smart grids have spurred the development of small-scale photovoltaic power generation, with micro inverters becoming the preferred choice for such systems due to their

Design of Photovoltaic Micro-Inverter

In order to find the best solution to reduce costs and improve efficiency and reliability of micro-inverter, topologies of micro-inverter in photovoltaic power generation system are reviewed in

6 FAQs about [Small photovoltaic inverter design]

Can a micro-inverter convert DC power from a photovoltaic module to AC?

The objective of this work is to design and build a novel topology of a micro-inverter to directly convert DC power from a photovoltaic module to AC power. In the proposed microinverter, a structure with two power stages, which are DC/DC and then DC/AC converters, is used.

How does a PV inverter work?

The PV panel is a non-linear DC source; an inverter must feed current into the grid, and a maximum power tracking algorithm must maximize power from the panel. Therefore the key challenge in any PV inverter system design is to feed a clean current into the grid while maintaining the maximum power point of the panel.

What is a microinverter?

In the proposed microinverter, a structure with two power stages, which are DC/DC and then DC/AC converters, is used. The inverter is designed capable for future integration of battery as a buffer in between the DC/DC and DC/AC converters.

Which microcontroller is best for a PV inverter?

The localized MPPT at each panel improves the performance of the system under partial shading and unmatched panel conditions. The Texas Instruments C2000 microcontroller family, with its enhanced peripheral set and optimized CPU core for control tasks, is ideal for controlling the power conversion. Figure 1. Grid Tied PV Inverter

How to control a PV micro inverter?

This section describes the details of software implementation of control of PV micro inverter. PV inverter control requires closed loop control of the DC-DC and DC-AC stage. PWM switching rates of the power stages are chosen such that only a single, fast 50-KHz ISR is needed for controlling the DC-DC flyback and the DC-AC inverter stage.

What is the TI solar micro inverter board design?

The micro inverter board design follows a control card concept; therefore, a different control card can be used depending on the system requirements. The TI Solar Micro Inverter board produces high voltages and should only be handled by experienced power supply professionals in a lab environment.

Learn More

- Design of home photovoltaic grid-connected inverter

- Inverter Photovoltaic System Design

- Montevideo Off-grid Photovoltaic Power Generation Small Inverter

- Vietnam photovoltaic energy storage inverter design

- Photovoltaic inverter inf

- Photovoltaic panels directly supply power to the inverter

- How much does a Sanaa photovoltaic inverter cost

- Baijidian Photovoltaic Inverter Manufacturer

- Photovoltaic inverter grid disturbance

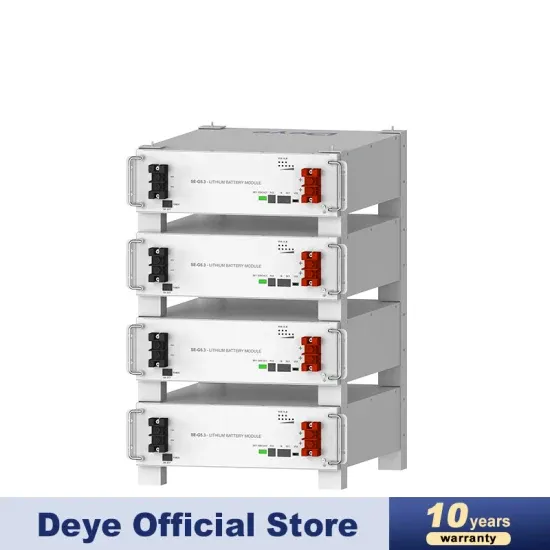

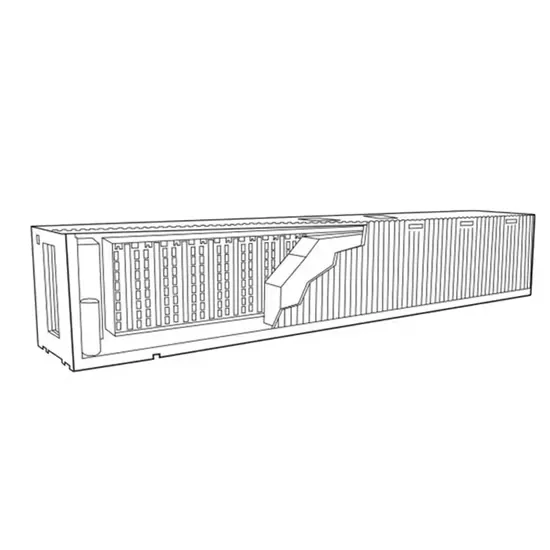

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.