Solar inverter size: Calculate the right size for

2 days ago · Discover why solar inverter sizing is important for efficiency and performance. Learn how to calculate the ideal inverter size for your solar

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · The bifacial dual sided glass module (G2G) generates more electricity by converting direct, radiant and scattered solar energy on both the front and the back side of the module.

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Inverter Matching for Trina Solar''s Vertex Series

Sep 9, 2021 · Inverter Ecosphere for 210 Modules As of June 2021, mainstream inverter suppliers around the world have launched high-current inverters that match the 210 modules. The

Glass-Glass Modules: The Revolution for Solar Installers –

Dec 18, 2024 · Manufacturers like JA Solar, Trina Solar, and Jinko Solar offer glass-glass modules that stand out for their high resistance to extreme weather conditions and improved

Solarspace Double Glass Photovoltaic Modules

Jul 19, 2023 · Thanks for choosing Solarspace Solar PV modules. This guide contains information regarding the installation and safe handling of Solar- space photovoltaic module (hereafter is

THE TRINA SOLAR VERTEX MODULE WHITE PAPER

May 28, 2020 · We take the shared-crossbeam support as an example (see Figure 11), which is a mainstream installation solution for bifacial double-glass modules to avoid backside shading.

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · modules can be mounted in landscape or portrait orientation. For the bifacial modules, in order to maintain the energy yield of module rear side, the distance between the

How does the double-glass design enhance the resistance to

Oct 31, 2024 · The double-glass design enhances resistance to potential-induced degradation (PID) primarily through its hermetic, symmetrical structure that better protects the solar cells

Single-glass versus double-glass: a deep dive into module

Oct 2, 2024 · For instance, the transition from 3.2mm to 2.8mm for single-glass modules and 2mm for double-glass modules, and even to 1.6mm, necessitates a careful consideration of the

Installation and User Manual

Jul 21, 2025 · Do not touch or handle GG modules with broken glass or separated frames, unless the modules are disconnected and you are wearing proper personal protective equipment.

YINGLI SOLAR GG MODULES Installation and User Manual

Nov 13, 2023 · This manual applies to photovoltaic GG modules ("GG modules", also commonly known as Double Glass Modules) manufactured by Yingli Energy Development Company

Solis Seminar 【Episode 37】:Key Points of Inverter Selection

Dec 15, 2021 · Due to the aesthetic needs of BIPV projects, solar panels are more biased towards power-generating glass, double-glass cells and thin-film cells. Thin-film cells have excellent

How does the double-glass design enhance the resistance to

Oct 31, 2024 · By limiting moisture penetration, the double-glass design inhibits this ion migration, thereby lowering PID risk. Symmetrical structure and neutral mechanical stresses: In double

JA SOLAR PV MODULES INSTALLATION MANUAL

Jan 29, 2019 · The modules clamps must not contact the glass directly or deform and damage the glass in any cases, clamp need embedded with the rubber washer, which plays a buffer

JA Solar PV Single-glass Modules Installation Manual

Jan 8, 2025 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules. This Manual

Preparatory study for solar modules, inverters and systems

Dec 6, 2023 · The BNAT point allows for future innovation and product‐differentiation after the introduction of measures. The MEERP guidance also notes that in other preparatory studies

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance produc

Solis Seminar【Episode 50】: How do inverters adapt to high-power PV modules?

Dec 26, 2022 · An inverter configured for use with high power PV modules must have a high enough string or MPPT input current capacity to maximise generation from the modules. The

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

有道翻译_文本、文档、、在线即时翻译

有道翻译提供即时免费的中文、英语、日语、韩语、法语、德语、俄语、西班牙语、葡萄牙语、越南语、印尼语、意大利语、荷兰语、泰语全文翻译、翻译、文档翻译、PDF翻译、DOC

How does the high power PV module adapt to the

following requirements: 1. Higher String or MPPT Current If the inverter MPPT current is lower than the specified modules, the input current will be limited durin. inverter operation, resulting

6 FAQs about [Does the inverter of double-glass modules need to be enlarged ]

Which Inverter should be used with high-power PV modules?

As you can see, the operating current and short-circuit current of the high-power PV module are both large. The current of the PV module corresponding to 210mm can reach more than 17A. Therefore, any inverter being considered for use with high-power PV modules must meet the following requirements: 1. Higher String or MPPT Current

What is double glass PV module?

Double glass PV module is known as the ultimate solution for the module encapsulation technique. Although double glass modules have many advantages, they are not yet widely used in photovoltaic power plants, for which one important reason is the large power loss due to the transmission of light in the cell gap region.

Why is white double glass PV module more powerful than transparent?

Due to the high reflectance of white EVA, the power of white double glass module is higher than that of transparent double glass module by 2-4%. Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun.

Can A solis inverter be used with high power PV modules?

An inverter configured for use with high power PV modules must have a high enough string or MPPT input current capacity to maximise generation from the modules. The maximum input current of Solis inverters reaches 18A and the maximum MPPT current reaches 36A. This allows for applications across Residential, C&I, and Utility scale systems.

Are double glass PV modules safe?

Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun. According to the literature, double glass also has some potential risks besides the abovementioned advantages.

What is the encapsulation reliability risk of double glass module?

The double glass module is superior to the conventional single glass module, which indicates that the encapsulation reliability risk of double glass module is good without delaminating risk. 90 Jing Tang et al. / Energy Procedia 130 (2017) 87–93 4 J. Tang et al./ Energy Procedia 00 (2017) 000–000 Fig. 3.

Learn More

- Double-glass thin-film photovoltaic modules

- Does a solar roof need an inverter

- Do I need an inverter to install a storage battery

- Differences between bifacial modules and double-glass modules

- Does a commercial 500kwh energy storage cabinet need an inverter

- Modules included in the off-grid inverter

- Do I need to select the power for outdoor inverter

- Actual power of double-glass photovoltaic modules

- Multicrystalline double-glass photovoltaic modules

Industrial & Commercial Energy Storage Market Growth

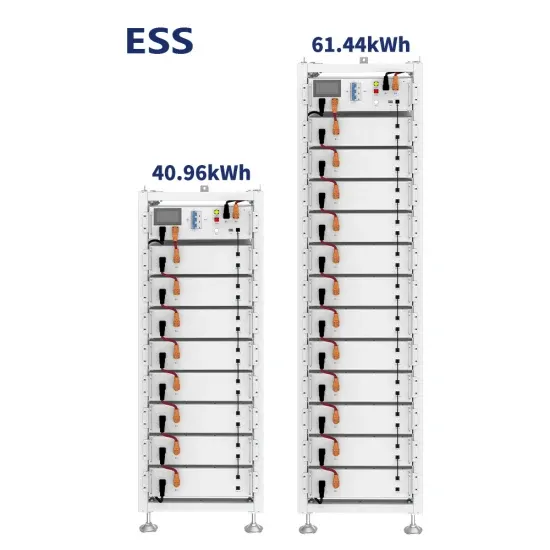

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.