Design of axial flux permanent magnet synchronous generators

In this paper an overview of waste water treatment process was demonstrated and a turbine was analytically designed for a potential hydro power station. After that, cored and coreless axial

Micro Axial Flow Turbine Generators for Hydropower

The micro axial flow turbine generator is an innovative and efficient solution for harnessing the power of flowing water to generate electrical energy. These compact units are designed to

High Efficiency Axial Flow Water Turbine Generators

Types of Axial-Flow Water Turbines Axial-flow water turbines are categorized based on functionality and characteristics. They majorly involve water movement through the turbine''s

Investigation and optimization into flow dynamics for an axial flow

Aug 15, 2024 · In the eastern route of China''s South to North Water Diversion Project, axial-flow pumps play a crucial role, and there are 51 axial-flow pumping stations. In the season of

Study of vortex dynamics in a solar tower vortex generator

Sep 15, 2024 · This study investigates the potential for enhancing flow efficiency through the implementation of vortex generators. This study advances the fundamental knowledge of flow

Research and Development of a Large-Scale Axial-Flux Generator

Oct 28, 2024 · A developed large-scale axial-flux generator is used for electricity generation at a run-of-river hydrokinetic power system. The system is to be used in a river with a high

Axial-flow turbines for low head microhydro systems

Jan 1, 2009 · However, the shaft power calculated in this manner equated with the shaft power calculated from potential energy and efficiencies allows a solution for the axial and

DESIGN AND PERFORMANCE TESTING OF 5KW AXIAL

Nov 16, 2016 · e power station, like the dam, scroll casing, the water intake gates and the blades. Axial Flow type Kaplan turbine is suitable for low head and large flow rate. This paper will dem

A survey on low speed low power axial flux generator design

Oct 14, 2022 · Axial Flux Generator is a permanent magnet generator commonly used for low-speed power generation using wind power. This generator can generate useful amount of

Photovoltaic Synchronous Generator: Architecture and Control

Nov 13, 2019 · This article presents a novel ac coupled solution that transforms an existing grid-following PV system to a grid-forming one without any hardware and software modification of

Axial Flux Permanent Magnet Synchronous Generators for

A pico hydropower plant is an energy harvesting system that allows energy production using the power of the water flowing in small watercourses, and in water distribution network. Axial Flow

Axial Flux Permanent Magnet Generator

Feb 3, 2014 · After considering an array of generator designs, an axial flux permanent magnet design was elected. This design was chosen because it is easier to manufacture and also

(PDF) Hydrokinetic Power for Isolated Communities

The proposed Hydrokinetic Power Generation System coupled to the Axial-Flow Generator may be a viable option for communities close to rivers with specific hydrological characteristics,

Power control of an autonomous wind energy conversion

Nov 30, 2024 · Similarly 26, explores hybrid systems combining wind, photovoltaic, and diesel generators with batteries for autonomous power generation, yet this paper highlights the

Hydrokinetic Power Generation System coupled to the Axial-Flow Generator

Decentralized power generation is an option to serve communities that survive in places without electricity or isolated from urban centers or in areas with intermittent electricity coming from

Axial Flux Permanent Magnet Synchronous Generators for Pico

A pico hydropower plant is an energy harvesting system that allows energy production using the power of the water flowing in small watercourses, and in water distribution network. Axial Flow

Axial Flow Water Wheel Electricity Generator Water

May 23, 2025 · Product Features Axial flow turbine generator unit is widely used for low water head such as small river, small dam, etc. The mini axial turbine generator is made by

Design, manufacture and installation of pv structures

Axial Structural Solutions is a benchmark in the design and manufacture of fixed structural systems and solar trackers for photovoltaic installations. From the beginning, as expert

Axial Flow Turbines and Working Principles

Jul 19, 2022 · Axial Flow Gas Turbine Axial flow turbine is the most broadly utilized gas turbine using a compressible fluid. Axial flow turbines supply most gas turbine units and are more

Photovoltaic generator model for power system dynamic studies

Nov 1, 2020 · This paper reviews the state-of-the-art PV generator dynamic modeling work, with a focus on the modeling principles of PV generator for the power system dynamic studies.

Axial Flux Permanent Magnet Synchronous Generators

Sep 21, 2022 · Abstract: A pico hydropower plant is an energy harvesting system that allows energy production using the power of the water flowing in small watercourses, and in water

6 FAQs about [Axial flow generator for photovoltaic power station]

What is axial flux generator?

Axial Flux Generator is a permanent magnet generator commonly used for low-speed power generation using wind power. This generator can generate useful amount of power even under very low revolutions per minute (rpm). Over the last three decades, many researchers and engineers have developed plethora of designs with varying success.

Are axial flux generators suitable for small-scale low wind speed deployments?

From the comprehensive survey of many axial flux generator designs, many designs fail to live up to be feasible for practical small-scale low wind speed deployments. This is mainly due to the fact that most of the designs expect rpm of over 200 to generate reasonable amount of power.

How much power can a dual rotor axial flux generator generate?

Dual rotor axial flux generator with labelled parameters for optimisation. This work describes a reasonably practical design that can generate around 100 W of power at 100 rpm. This is very close to real life wind energy applications as higher rpms are not very practicable for wind energy.

What is a slotless axial flux generator?

Toroidal slotless axial flux generator was presented by Chalmers et al. . Their design consisted of many magnets due to slotless generators requiring more magnets to maintain adequate magnetic flux in the circuit. They constructed both 1.5KW and 5KW experimental generators with 24 magnetic poles.

Why do axial flux generators have rotors?

Looking at the most of the designs in stators and rotors of axial flux generators, it is quite obvious that this is mainly due to cancellation of voltage and hence power due to coil shapes, magnet shapes and their close proximity to each other in each revolution.

What is a 3 phase axial generator?

The design has three phase axial generator that consists of 4 poles (coils) and four different alternating current circuits for each phase. The material used for each coil is copper and the permanent magnets used at each rotor were Neodymium Magnets (N52).

Learn More

- Small photovoltaic power station generator in West Asia

- Cooling method of photovoltaic power station generator set

- The voltage generated by the photovoltaic power station generator

- Andorra photovoltaic power station generator installation

- Amman Photovoltaic Power Station Generator Manufacturer

- Photovoltaic power station generator assembly

- Photovoltaic power station generator steel mill

- Photovoltaic power station generator impeller

- How many combiner boxes are used in a 500kw photovoltaic power station

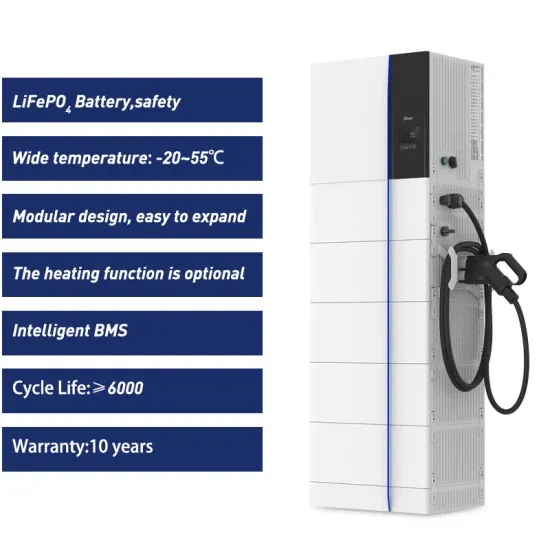

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.