How many combiner boxes are needed for a 1mw

It is used in PV (photovoltaic) systems,and usually contains fuses or circuit breakers to protect the system from over-current conditions. A solar combiner box is not necessary for all PV

PV Combiner Box: Ultimate Guide 2025 & ETEK Solar Solutions

4 days ago · If you''re building a solar power system, whether for your home, business, or a large-scale utility project, a PV combiner box is a critical component you can''t overlook. This guide

Photovoltaic system: electrical equipments selection

Dec 20, 2019 · 150kW to 500kW Grid connected PV system (Large building and farm) Three phase inverter with more than two string combiner boxes Typically, 150kW to 500kW single

How Many Combiner Boxes Does Your PV Array Really

Calculating the optimal number of combiner boxes for photovoltaic arrays. These unsung heroes of solar installations play ninja-like roles in managing current, reducing wiring costs, and

Photovoltaic power station combiner box

Leading Manufacturer Protects Solar Power Safety. The selection of a PV combiner box is a critical link to ensuring the efficient and safe operation of a PV power station. It involves

What is the total power of the photovoltaic combiner box

Leading Manufacturer Protects Solar Power Safety. The selection of a PV combiner box is a critical link to ensuring the efficient and safe operation of a PV power station. It involves

Solar Combiner Box Essentials: Beginner''s Guide

Apr 28, 2022 · A solar combiner box contains the following components: Circuit Breaker A switch may be used to disconnect or isolate a circuit manually, or it

PV combiner box comprehensive analysis

May 13, 2025 · The combiner box takes these 16 input wires and consolidates them into just two output wires (one positive, one negative) that then run to the inverter. Reduced Wiring

Design of combiner box for photovoltaic power station

Leading Manufacturer Protects Solar Power Safety. The selection of a PV combiner box is a critical link to ensuring the efficient and safe operation of a PV power station. It involves

How to Connect Solar Panels to a Combiner Box: A Step-by

Jan 10, 2025 · Connecting solar panels to a combiner box is a crucial step in setting up a solar power system. This process consolidates multiple strings of solar panels into a single output,

6 FAQs about [How many combiner boxes are used in a 500kw photovoltaic power station]

What is a solar combiner box?

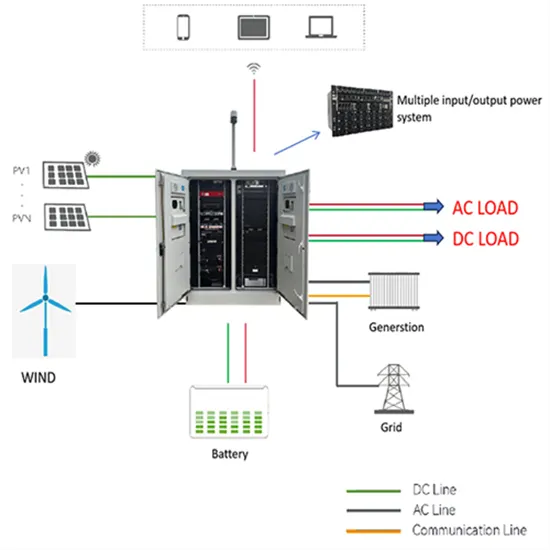

Solar combiner boxes are essential components in solar photovoltaic (PV) systems, designed to consolidate the outputs of multiple solar panel strings into a single output for connection to an inverter. There are various types of combiner boxes tailored to meet specific needs and configurations in solar installations. Here are the primary types:

Do you need a solar combiner box?

Adaptability: While smaller residential systems may not require a combiner box if they have only one to three strings, larger systems—ranging from four strings up to thousands—benefit greatly from their use. This adaptability makes combiner boxes suitable for both residential and commercial applications. II. Basics of PV Solar Combiner Boxes

Why do solar panels need a combination box?

Efficiency is the hallmark of any successful solar installation. Combiner boxes help improve the overall efficiency of the photovoltaic system by optimizing the wiring structure and integrating the DC output. Combiner boxes are designed to accommodate the inherent scalability and flexibility of solar installations.

Can I combine multiple solar array strings using a combiner box?

The following is a discussion on the requirements for combining multiple solar array strings using a combiner box. NEC Article 690.9 (A) states the following exception with regards to solar module overcurrent protection:

Why is a combination box important in a solar system?

In a vast solar system, each element plays a vital role in ensuring optimal performance and efficiency. Combiner boxes play an important role in photovoltaic (PV) installations.

What is a combiner box?

In off-grid applications, combiner boxes are crucial for consolidating multiple solar panel outputs into a single DC output that feeds into battery storage systems or DC loads. For example, in remote areas where grid access is limited, an off-grid solar system can utilize a combiner box to manage inputs from various panels efficiently.

Learn More

- How many photovoltaic combiner boxes are there

- How big of an energy storage station should be supported with a 1gw photovoltaic power station

- How is the photovoltaic power generation of the Sri Lanka communication base station inverter

- Photovoltaic power station combiner box

- Photovoltaic power station combiner box power supply improvement

- How is the photovoltaic power generation of the Tehran communication base station inverter

- Italian photovoltaic off-grid energy storage power station company

- How does Eritrea s telecommunications BESS power station charge

- How many watts of power does a photovoltaic panel usually have

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.