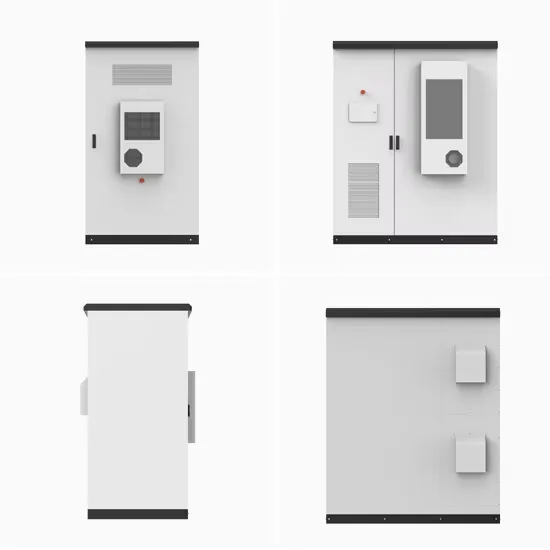

Photovoltaic power station combiner box

Leading Manufacturer Protects Solar Power Safety. The selection of a PV combiner box is a critical link to ensuring the efficient and safe operation of a PV power station. It involves

No more combiner boxes in photovoltaic power stations

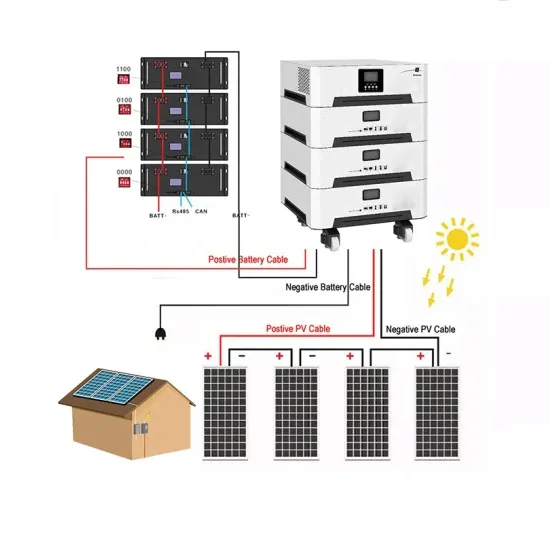

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

MV-inverter station: centerpiece of the PV eBoP solution

MV-inverter station: centerpiece of the PV eBoP solution Practical as well as time- and cost-saving: The MV-inverter station is a convenient "plug-and-play" solution offering high power

Optimizing Photovoltaic Power Stations The Critical Role of

May 20, 2025 · Meta Description: Discover how photovoltaic power station inverters and combiner boxes work together to enhance solar energy efficiency. Learn industry-specific optimization

Installation of combiner box in photovoltaic power station

About Installation of combiner box in photovoltaic power station Mount the combiner box and secure it with four screws, as shown below. Use 4–10 mm2, 600 V insulated cables. Strip 8

How to Select the Right PV Combiner Box: Key Parameters

Mar 17, 2024 · The selection of a PV combiner box is a critical link to ensuring the efficient and safe operation of a PV power station. It involves considering multiple parameters and factors,

Understanding Solar Combiner Boxes: Key to Efficient PV

PV convergence box is one of the core components of PV power generation system and plays an irreplaceable role in the whole PV power generation system. It not only undertakes the

Improvement in Solar Power Station O&M: Fonrich DC

Aug 12, 2025 · The RS485 Modbus-RTU and industrial-grade wireless communication ensure stable remote monitoring without connectivity issues. Flexible Power Supply Design: It draws

Photovoltaic power generation combiner box construction

The combiner box is a key component in the photovoltaic power generation system, responsible for collecting direct current (DC) from multiple photovoltaic modules and 1500v Surge

Application and development trends of intelligent combiner boxes

In the future photovoltaic market, smart combiner boxes will undoubtedly become an important part of the standard configuration of photovoltaic power plants and contribute to the

Installation of combiner box in old photovoltaic power

Mar 9, 2024 · What is a PV combiner box wiring diagram? Overall,a PV combiner box wiring diagram is a valuable tool in the installation and maintenance of a solar energy system. It

Photovoltaic power station combiner box

When selecting a photovoltaic (PV) combiner box, several key parameters must be considered to ensure the efficient operation and safety stability of the PV power station. Why should you

What is Combiner Box

2 days ago · A combiner box, also known as a junction box, is a crucial electrical enclosure widely applied in photovoltaic (PV) systems, electrical power distribution networks, and diverse

6 FAQs about [Photovoltaic power station combiner box power supply improvement]

How do combiner boxes improve solar energy production?

Careful operational management can drastically increase reliability and efficiency for PV systems; furthermore, as photovoltaic technology develops, combined boxes will continue to innovate and upgrade themselves for reliable solar energy production. Explore the functions and operational management of PV combiner boxes in solar power systems.

What is a photovoltaic AC combiner box?

The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC output side of the inverter and the grid connection point/load. It is internally equipped with input circuit breakers, output circuit breakers, and AC lightning arresters.

How do you manage a photovoltaic combiner box?

Effective operational management is crucial to the performance and longevity of photovoltaic (PV) combiner boxes. Here is an outline of essential aspects of maintenance and management that ensure these systems operate efficiently and reliably. 1. Regular Inspection and Maintenance Services

What is a solar combiner box?

Solar combiner boxes are essential components in solar photovoltaic (PV) systems, designed to consolidate the outputs of multiple solar panel strings into a single output for connection to an inverter. There are various types of combiner boxes tailored to meet specific needs and configurations in solar installations. Here are the primary types:

What is a PV combination box?

What is a PV Combiner Box? A PV Combiner Box is a device that brings together the output from multiple solar panel strings and channels it into a single output going to the inverter. It simplifies wiring, improves safety, and keeps your solar setup neat and manageable. In a typical solar power system, each string of panels generates DC electricity.

What is a PV combiner box?

The PV combiner box works like a toll plaza, organizing and streamlining traffic flow before it reaches the highway—in this case, the inverter. Beyond just combining outputs, it plays a key role in string-level integration by offering protection (via fuses or breakers) and sometimes performance monitoring for each individual string.

Learn More

- Outdoor ip65 photovoltaic combiner box power supply

- Photovoltaic combiner box power supply

- Photovoltaic power station combiner box

- Photovoltaic power generation combiner box in Alexandria Egypt

- How many combiner boxes are used in a 500kw photovoltaic power station

- Marshall Islands installs photovoltaic energy storage power station

- What is in a communication base station uninterruptible power supply

- Skopje Base Station Power Cabinet Power Supply Equipment

- Marseille 5g communication base station power supply

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.