Fuel Cell Backup Power System for Grid Service and

Mar 22, 2018 · The study identifies the approaches on the fuel cell application through nano/microgrids for an extensive network of fuel cells as distributed energy resources. The

Hydrogen as a Transport Fuel

Jul 28, 2022 · Low-emission and hydrogen-fuelled vehicle technology Zero- and low-emission vehicles (ZEV/LEVs) are vehicles that emit no or low exhaust emissions from the on-board

Hydrogen-based energy for the port logistics of the future

Apr 14, 2022 · Rolls-Royce''s Power Systems business unit is supplying its latest mtu hydrogen technology for this purpose, in order to supply the future terminal with electrical energy and

H2FillS: Hydrogen Filling Simulation | Hydrogen and Fuel Cells

Feb 6, 2025 · H2FillS: Hydrogen Filling Simulation The Hydrogen Filling Simulation (H2FillS) software is a thermodynamic model designed to track and report on the transient change in

Fuel Cell Systems for Base Stations: Deep Dive Study

Aug 8, 2012 · Introduction and motivation for the study Fuel cell systems have long been considered suitable for remote stationary power applications with a high cost of downtime,

Fuel Cell Systems for Base Stations: Deep Dive Study

Aug 8, 2012 · Fuel cell systems have long been considered suitable for remote stationary power applications with a high cost of downtime, such as mobile base stations. Fuel cell design and

Toyota Expands Commitment to Hydrogen Society with Fleet

ANAHEIM, Calif. (April 28, 2025) – Toyota Motor North America (Toyota) today reaffirmed its commitment to a Hydrogen Society at the 2025 Advanced Clean Transportation Expo,

Evaluation of Hydrogen Fuel Cell as a Backup Power for

May 29, 2025 · This paper evaluates hydrogen fuel cells as a promising alternative within smart grid contexts, examining their technical performance, efficiency, reliability, and environmental

Deployment of Fuel Cell Vehicles and Hydrogen

Oct 30, 2024 · Abstract: Hydrogen fuel cell vehicles can complement other electric vehicle technologies as a zero-emission technology and contribute to global efforts to achieve the

Hydrogen fuel cells could provide emission free

Jul 28, 2022 · Latham, New York – Hydrogen fuel cells packed into a pair of 40-foot-long shipping containers here ramped up on an overcast day early this

Hydrogen Storage | Hydrogen and Fuel Cells | NREL

Feb 6, 2025 · Hydrogen Storage With support from the U.S. Department of Energy (DOE), NREL develops comprehensive storage solutions, with a focus on hydrogen storage material

Recent development of hydrogen and fuel cell

Nov 1, 2021 · It is obvious that hydrogen and fuel cells can meet the rising demands for societal development and provide the possibility of covering most energy fields. Therefore, many

6 FAQs about [Hydrogen fuel cell board container base station]

What is Ricardo's hydrogen fuel cell module?

Initially developed as part of the Sustainable Hydrogen Powered Shipping (sHYpS) Horizon Europe project for the maritime sector, Ricardo’s multi-stack hydrogen fuel cell module is designed to deliver high energy output with zero emissions.

What is a gencell box?

GenCell BOX is a mandatory component of every telecom base station and other critical devices that must remain powered. Rugged, reliable, and resilient, the GenCell BOX™ leverages hydrogen fuel cells to output 48V of long-duration, zero-emission direct current power. No more outages, no more maintenance, just power as planned.

What are hydrogen-based fuel cells used for?

Hydrogen-based fuel cells have been used for many years in applications such as light forklift trucks, enabling quick refueling, local zero emissions indoors, and simplified maintenance compared to traditional solutions.

How does Ricardo support the adoption of hydrogen technology?

To support the adoption of hydrogen technology, Ricardo has also developed a containerised solution, able to combine multiple fuel cell modules, enabling power output to be scaled up to 3MW per container, with the DC-DC power conversion on board, all without sacrificing efficiency or durability.

Where can I find information about hydrogen & fuel cell applications?

Available online: https: //# (accessed on 10 February 2022). Snapshot of Hydrogen and Fuel Cell Applications in the US -Examples, US Department of Energy. Available online: https: // (accessed on 26 January 2022).

What is a modular fuel cell system?

Its modular architecture integrates multiple fuel cell stacks to provide unmatched power density, and scalability while meeting the evolving energy demands of diverse applications, such as maritime, stationary power generation, rail and off-highway.

Learn More

- Berlin container communication base station photovoltaic site energy

- Bhutan container communication base station battery maintenance site

- Base station communication equipment baseband board

- Small distribution cabinet container base station

- Lead-acid battery connected to container base station

- Analysis of energy storage battery container usage base station

- 4MW Base Station Container Energy Storage Power Station Price

- Can the base station be removed from the container

- Distribution cabinet container base station

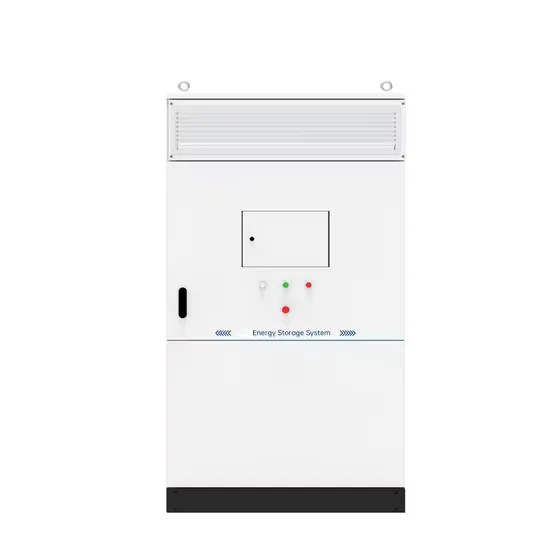

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.