Lead-Acid Battery Management

Oct 7, 2024 · Lead-acid batteries contain sulphuric acid and large amounts of lead. The acid is extremely corrosive and is also a good carrier for soluble lead and lead particulate. Lead is a

GRID CONNECTED PV SYSTEMS WITH BATTERY ENERGY

May 22, 2023 · The term battery system replaces the term battery to allow for the fact that the battery system could include the energy storage plus other associated components. For

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

GS Yuasa E-Learning Support Documentation

Mar 20, 2019 · Overview: This support documentation has been designed to work in conjunction with the GS Yuasa e-learning course "Lead Acid Battery Construction" and covers of the

Battery Technologies for Grid-Level Large-Scale Electrical

Jan 8, 2020 · Furthermore, several types of battery technologies, including lead–acid, nickel–cadmium, nickel–metal hydride, sodium–sulfur, lithium-ion, and flow batteries, are

How to ship lead-acid batteries? What should be

Sep 29, 2022 · Lead-acid batteries belong to the eighth category of dangerous goods, transportation requires a license, and export lead-acid batteries must

Used Car Battery Storage Container | Used Lead

4 days ago · The World''s Safest Lead Acid (Car) Battery Container UNISEG''s Battery Transport & Storage (BTS) Container was specifically designed for the

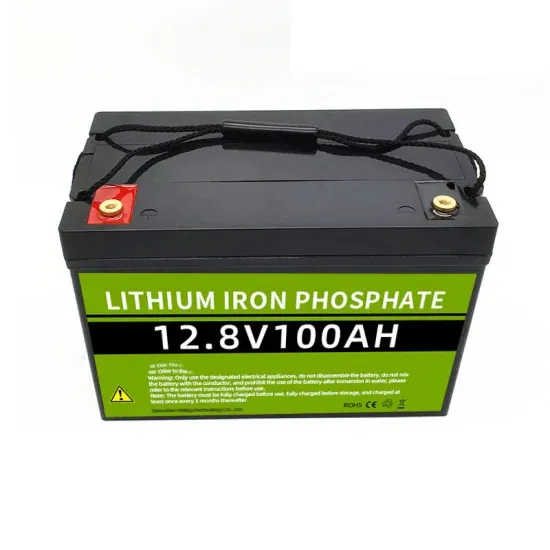

How about base station energy storage batteries

Apr 7, 2024 · Base stations primarily utilize lithium-ion and lead-acid batteries. Lithium-ion batteries are favored for their higher energy density, longer

Containerized Battery Energy Storage System

Jun 28, 2024 · Types of BESS • Lithium-ion batteries: These containers are known for their high energy density and long cycle life. • Lead-acid batteries:

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Lead–acid batteries are easily broken so that lead-containing components may be separated from plastic containers and acid, all of which can be recovered. Almost complete

1 Battery Storage Systems

Feb 2, 2018 · 14 13 2.1. Lead acid batteries 15 The lead-acid battery was invented in 1859 by French physicist Gaston Planté and it is the able battery technology. There are ndamental

Rule 26-506 Ventilation requirements for vented lead

Aug 25, 2021 · Background: Questions have been raised about ventilation requirements for lead acid batteries. There are two types of lead acid batteries: vented (known as "flooded" or "wet

6 FAQs about [Lead-acid battery connected to container base station]

Where do lead acid batteries come from?

Pacific Batteries Ltd in Fiji imports bulk lead for the manufacture of lead acid batteries. There is no recycling of lead acid batteries recovered in Fiji for their operations. ASPA in American Samoa has collected a container of batteries for shipment to New Zealand. This operation was subsidised by the EPA to help cover costs.

What is a drained lead acid battery?

Undrained Lead Acid Batteries also termed wet batteries. Drained Lead Acid Batteries also termed drained batteries. The entire process of recycling requires a co-ordinated approach and is outlined below.

What is a lead acid battery?

Lead–acid batteries may be flooded or sealed valve-regulated (VRLA) types and the grids may be in the form of flat pasted plates or tubular plates. The various constructions have different technical performance and can be adapted to particular duty cycles. Batteries with tubular plates offer long deep cycle lives.

Are lead-acid batteries a good choice for energy storage?

Lead–acid batteries have been used for energy storage in utility applications for many years but it has only been in recent years that the demand for battery energy storage has increased.

Can lead acid batteries be recycled?

Lead-acid batteries contain components that have the ability to cause serious environmental contamination. In those PICs without private recyclers or even in areas of countries that do have recycling, batteries are left abandoned or disposed inappropriately to the environment. The lead in old lead acid batteries should be recovered and reused.

What are lead-acid batteries used for?

Lead-acid batteries are imported into PICs and are widely used in cars, trucks, boats, motorcycles, tractors and a range of other mechanical equipment requiring power. Lead-acid batteries contain sulphuric acid and large amounts of lead. The acid is extremely corrosive and also a good carrier for soluble lead and lead particulate.

Learn More

- Lead-acid battery deformation container base station

- Telecom lead-acid battery container base station

- Communication base station lead-acid battery UPS host

- Battery display cabinet container base station

- Integrated base station lead-acid battery assembly

- Ankara communication base station lead-acid battery photovoltaic power generation solution

- Base station battery connected to inverter

- Guatemala small communication base station lead-acid battery approval

- Battery Storage Warehouse Container Base Station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.