Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

Lead-acid battery assembly knowledge

The lead acid battery construction course consists of the following modules: Overview of components Battery container & lid Plates & separators Final assembly & filling Charging &

Simple electrode assembly engineering: Toward a multifunctional lead

Sep 1, 2024 · To address this challenge, we optimized the configuration of conventional Pb-acid battery to integrate two gas diffusion electrodes. The novel device can work as a Pb-air battery

Advanced Battery Management Systems with Integrated Battery

Sep 28, 2022 · Batteries are a key technology in electric vehicles (EVs), microgrids, smartphones, laptops, etc. A battery management system (BMS) is needed in order to ensure the safety and

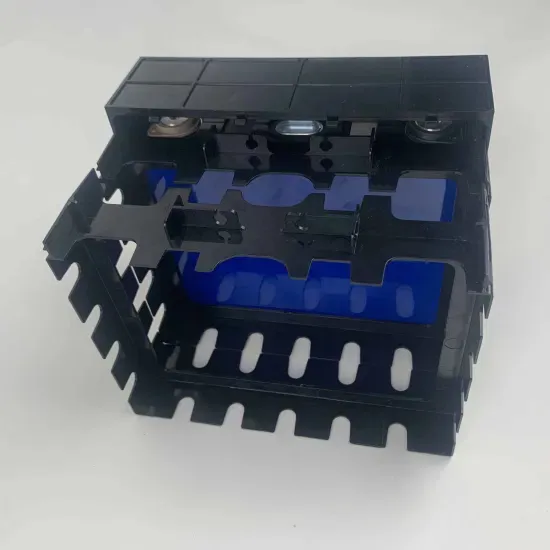

The Basics of Lead-Acid Battery Assembly

Jan 6, 2025 · Lead-acid batteries are used in a variety of automotive, industrial and traction applications. lead-acid battery assembly They consist of positive and negative plates,

Assembly line for battery modules and battery packs

6 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Portable Solar-Station with Integrated Battery

The Volta 12V 80Ah lead-acid battery was set to an initial charging level of 60.0%. The increment of percentage from 60.0% to 60.02% in 20 seconds suggests that the charging mechanism is

US Base Station Battery Solutions | HuiJue Group E-Site

Oct 26, 2024 · Traditional lead-acid batteries—still used in 61% of sites—lose 30% capacity at -20°C. During 2023''s winter storms, Verizon alone deployed 12,000 temporary generators,

Fully Automatic Automotive Battery Assembly Line

Leko''s fully automatic assembly lines consist of multiple stations. The Leko assembly lines are fully designed and integrated as fully automatic assembly lines, with various options

Easily Integrated Automobile Battery Assembly Line

Jul 10, 2025 · The automatic lead-acid battery assembly line is an efficient and precise battery production equipment designed for the assembly, welding, liquid filling, and sealing processes

Optimized lead-acid grid architectures for automotive lead-acid

Mar 10, 2021 · A variety of technological approaches of lead-acid batteries have been employed during the last decades, within distinguished fabrication features of

Wirtz – Leko Brand -Fully Automatic Motor Cycle Battery Assembly

Leko is fully owned and operated by The Wirtz Group of Companies. For over 20 years, Leko has been designing, installing, and improving lead acid battery assembly line equipment. Leko''s

Lead-acid battery use in the development of renewable energy systems

Jun 1, 2009 · Lead-acid batteries with their advantages of low price, high-unit voltage, stable performance, and a wide operating temperature range, face an exciting challenge as major

Lead Acid Battery Assembly: Step-by-Step Guide

Jul 26, 2024 · In this article we will try to understand the procedure for the lead-acid battery assembly and equipment needed for this. Technicians will first connect the plates, either in

The Manufacturing Process of a Lead-Acid Battery

Nov 11, 2021 · Fortunately for battery manufacturers, automated equipment is available to maximize efficiency and precision at virtually every step of the process. Plate production and

Application of energy storage lead-acid batteries in 5G base stations

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Battery Assembly Equipment – Infinite Industries

For over 20 years, Leko has been designing, installing, and improving lead acid battery assembly line equipment. Leko''s fully automatic assembly lines consist of multiple stations.

Communication Base Station Lead-Acid Battery: Powering

Why Are Lead-Acid Batteries Still Dominating Telecom Infrastructure? In an era where lithium-ion dominates headlines, communication base station lead-acid batteries still power 68% of global

Simple electrode assembly engineering: Toward a multifunctional lead

Electrochemical energy storage is a promising technology for the integration of renewable energy. Lead-acid battery is perhaps among the most successful commercialized systems ever since

Lead-acid Battery for Telecom Base Station Market

The telecom base station sector relies on lead-acid batteries due to their cost-effectiveness, reliability, and adaptability to harsh environments. Expanding 4G and 5G infrastructure in

6 FAQs about [Integrated base station lead-acid battery assembly]

What is a lead-acid battery?

Lead-acid battery also delivers the lowest CO 2 emissions throughout the life-cycle (a quarter of that for LIBs) , . Its excellent safety record makes it a reliable option for renewable energy integration, particularly suitable for smart grids and remote area power supplies .

What are recommended design practices and procedures for vented lead-acid batteries?

Abstract: Recommended design practices and procedures for storage, location, mounting, ventilation, instrumentation, preassembly, assembly, and charging of vented lead-acid batteries are provided. Required safety practices are also included. These recommended practices are applicable to all stationary applications.

Can hydrogen feedstock be used in modified PB-acid battery?

Besides, our cell provides a viable opportunity of using (portable) hydrogen feedstock in modified Pb-acid battery, which renders higher resilient for the energy storage system against fluctuated sustainable energy in stationary applications. We finally investigated the spent electrode after the stability test.

Can lead battery architecture optimization improve energy storage capacity?

It also switched among various operation modes easily with excellent stability, offering an efficient and flexible route for energy conversion. Our work showed the new potential of lead battery technology and demonstrated the importance of battery architecture optimization toward improved energy storage capacity.

What are the advantages of a lead-acid battery?

In fact, lead-acid battery has various intrinsic advantages that are not shared by other major counterparts. For instance, all the materials used are earth-abundant with low cost. Its simple electrode configuration and composition also lead to much lower energy cost during manufacturing and recycling , .

How can a conventional PB-acid battery be optimized for grid-scale energy storage?

The configuration of conventional Pb-acid battery was optimized via integrating with two gas diffusion electrodes, enabling multifunctional applications and opening up genuine opportunities for grid-scale energy storage. 1. Introduction

Learn More

- San Marino integrated communication base station lead-acid battery 6 25MWh

- Base station lead-acid battery cost

- Communication base station lead-acid battery sales information

- Communication base station lead-acid battery UPS host

- Bhutan communication base station lead-acid battery power generation

- Maintenance of battery energy storage system for integrated communication base station in Belize

- Montevideo Integrated Communication Base Station Battery Energy Storage System Maintenance

- Base station lead-acid battery power

- Lead-acid battery deformation container base station

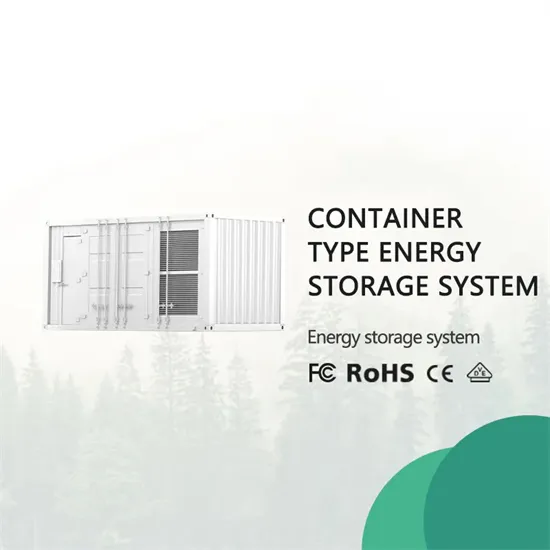

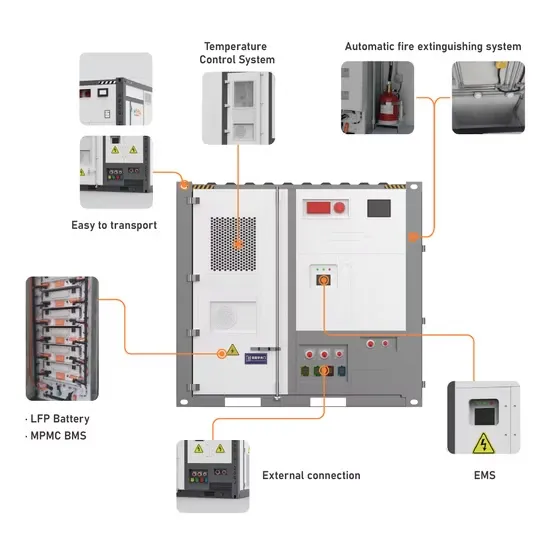

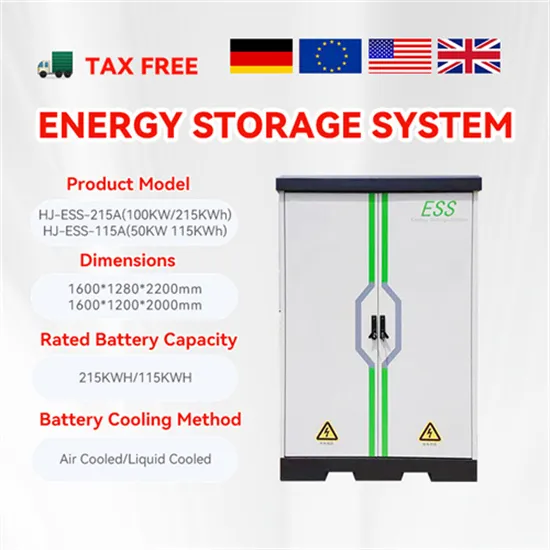

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

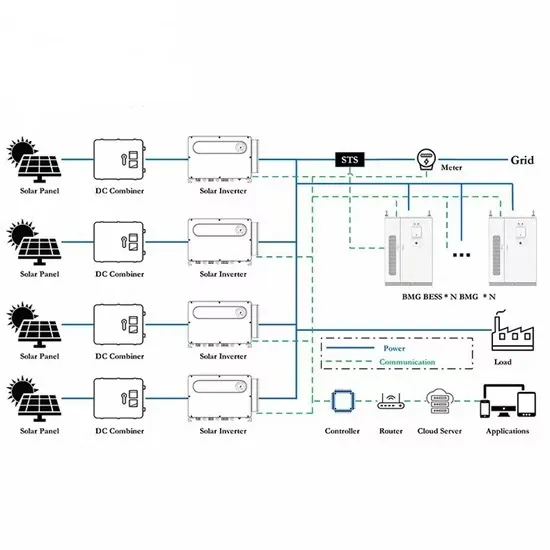

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.