What size inverter do I need for a refrigerator?

Feb 6, 2024 · You could run most refrigerators using a 1500-watt pure sine wave inverter. Inverters of this size and type can consistently supply 1500 Watts of

How big an inverter should I use for a 10KW

Under the Clean Energy Council rules for accredited installers,the solar panel capacity can only exceed the inverter capacity by 33%. That means for a typical 5kW inverter you can go up to a

10 Tips for Using a Power Inverter Correctly

Jan 24, 2020 · 2. Power inverter output power must be greater than the power of home appliances or electrical devices, especially for the appliances with high starting power, such as

请问48v10ah的锂电池能输出48v25a的电流吗?

Aug 23, 2021 · 如果电池组内,电池的并联数量够多,完全可以。 48V10AH是电容量单位,48V下的25A,是带载能力,也就是接负载时,最大的驱动电流能达到25A,这是2个概念。 在理想

Solar Inverter & Battery Sizing Calculator

Apr 30, 2025 · Choosing the correct inverter and battery size is crucial for every microgrid system. Our Solar Inverter and Battery Sizing Calculator provides a

How Big of an Inverter Do I Need to Run a Whole House?

Aug 6, 2024 · Industry best practices often recommend selecting an inverter with a capacity around 20-30% higher than your maximum load to accommodate future expansions and

How big an inverter should I use for a 10 megawatt

How do I choose a solar inverter size? To calculate the ideal inverter size for your solar PV system, you should consider the total wattage of your solar panels and the specific conditions

How Big an Inverter to Run a Microwave: Understanding

Is a pure sine wave inverter necessary for a microwave? While it is possible to use a modified sine wave inverter to run a microwave, a pure sine wave inverter is highly recommended for

How to Calculate the Right Inverter Battery

Feb 24, 2025 · Battery Capacity (Ah) = (Total Power Consumption in Watts × Backup Hours) ÷ Battery Voltage. This formula helps determine how long an

How big an inverter should I use for a 10kw photovoltaic

How big an inverter should I use for a 10kw photovoltaic module Suppose you have a 10 kW solar array installed in a location with an ambient temperature of 35°C and an altitude of 1500

How big an inverter can I run off my battery

Apr 28, 2016 · Re: How big an inverter can I run off my battery by Peter_n_Margaret » Thu Apr 28, 2016 1:31 pm ozwapet wrote: So your 1700 watts is about 130 amps being drawn out of the

How Big of a Power Inverter Do I Need? | Best Buy Guidebook

Sep 30, 2024 · You can''t really figure out how big of a power inverter you need if you''re unfamiliar with how an inverter works. You also need to have a basic know-how of how much power

Inverter Sizing: Can Your Inverter Be Too Big for Your Battery

Apr 14, 2025 · An inverter can indeed be too big for your battery bank. An oversized inverter might waste energy and raise operating costs. To prevent this, ensure the inverter size matches your

Calculate Battery Size for Inverter Calculator

Mar 14, 2025 · The Calculate Battery Size for Inverter Calculator helps you determine the optimal battery capacity needed to support your inverter system. By inputting critical parameters such

Inverter Size Calculator [Power Inverter, AC, DC,

Feb 7, 2025 · Calculate the ideal inverter size with the Inverter Size Calculator. Perfect for selecting inverters for homes, solar panels, or vehicles based on

How Do You Calculate the Appropriate Inverter Size for a

Oct 28, 2024 · To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

SOLAR PANEL SIZES AND WATTAGE EVERYTHING YOU

How big should a solar inverter be? Most installations slightly oversize the inverter, with a ratio between 1.1-1.25 times the array capacity, to account for these considerations. The size of the

How Big of an Inverter Can My Car Battery Handle?

Mar 26, 2025 · Calculating inverter demand sizing There is a theoretical limit to the amount of inverter power that can be supported by an automotive battery.

Can an Inverter Be Too Big for Your Battery System?

For a 12V 200Ah battery (2.4kWh), a 2000W inverter is ideal. Formula: Inverter Wattage ≤ (Battery Voltage × Ah Rating × 0.8). Factor in surge power needs but prioritize sustained

HOW BIG AN INVERTER DO I NEED FOR 10KW SOLAR

How big an inverter should I use for a 300w solar panel For a 300 watt solar panel, you need anywhere between 500-1500 watt capacity inverter.However, the exact size you need will

What Inverter Size Do You Need to Run a Freezer?

For the recommended inverter size, we have rounded off the results. For instance 350 watts plus 25% is 437 watts, but you won''t find an inverter with that capacity, so your best option is a

Understanding Battery Capacity and Inverter Compatibility

Aug 20, 2024 · How Long Can a 100 Ah Battery Run a 1000W Inverter? To estimate how long a battery can run an inverter, we need to consider the power draw and the battery''s capacity.

How big an inverter should be installed in a photovoltaic

Most installations slightly oversize the inverter,with a ratio between 1.1-1.25 times the array capacity,to account for these considerations. The size of the solar inverter you need is directly

How Big Of an Inverter Can My Car Handle | Expert Guide

Mar 22, 2023 · Before buying an inverter, knowing How Big Of an Inverter Can My Car Handle is important. The biggest inverter that can be used in a personal vehicle is the Magnum

6 FAQs about [How big an inverter can a 48v10ah bring]

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

What is the recommended battery size for an inverter?

Interpreting Results: Once you input the required data, the calculator will generate the recommended battery size in ampere-hours (Ah). For instance, if your power consumption is 500 watts, the usage time is 4 hours, and the inverter efficiency is 90%, the calculator might suggest a battery size of approximately 222 Ah.

Does a 24V inverter need a 12V battery?

An inverter’s battery capacity must match its voltage rating. If an inverter operates at 24V, the battery bank should be designed accordingly. For instance, using two 12V batteries in series provides 24V, while a 48V system requires four 12V batteries. Ensuring proper voltage alignment prevents system overloads and ensures stable performance.

What size inverter for a 200Ah battery?

To determine the appropriate inverter size for a 200Ah battery, consider the following: A 500VA inverter would be suitable, offering a balance between performance and battery life. For extended run times, consider larger inverters or additional batteries to meet higher power demands.

What is the capacity of an inverter battery?

The capacity of an inverter battery, measured in ampere-hours (Ah), determines how much power it can store and supply over time. A higher Ah rating means the battery can provide backup power for a longer duration before requiring a recharge. The basic formula for calculating battery capacity is:

What is the calculate battery size for inverter calculator?

The Calculate Battery Size for Inverter Calculator helps you determine the optimal battery capacity needed to support your inverter system. By inputting critical parameters such as power consumption, inverter efficiency, and desired usage time, this calculator provides a precise battery size recommendation tailored to your specific needs.

Learn More

- How big an inverter should I use for a 60v power supply

- How big an inverter should I use for 22kw

- How big a photovoltaic inverter does a water pump need

- How big an inverter is needed for home use

- How big a water pump should I add to a 2kw inverter

- How big an inverter should I use for a 3KW 220v motor

- How big a photovoltaic panel can an inverter carry

- How big of an inverter can I use for a 150ah lithium battery

- How big a photovoltaic project can a 50kw inverter support

Industrial & Commercial Energy Storage Market Growth

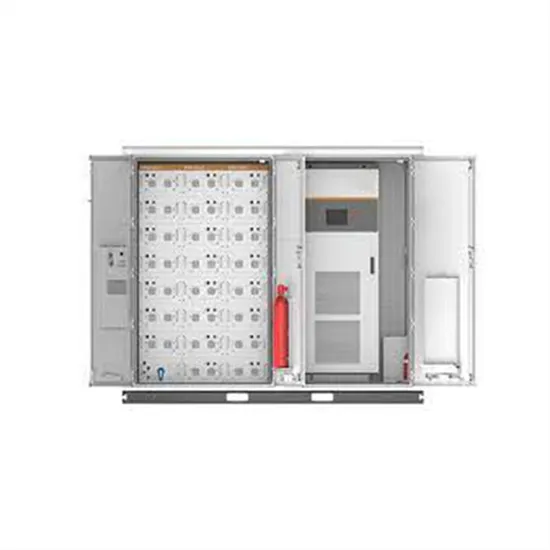

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.