Water Pump and Inverter Compatibility: The Ultimate Guide

Aug 24, 2024 · When selecting an inverter for a water pump, consider the following factors: Output Power: The inverter''s output power must be sufficient to handle the starting and

How big a water pump does a 2kw inverter use

Determining the correct size of the inverter is key to ensuring the water pump operates effectively. The inverter''s capacity should be at least five times the pump''s power rating to handle the

How big a water pump can a 2kw inverter use

To determine the appropriate size of a water pump for a 2kW inverter, consider the following:Pump Power Calculation: For a pump with a flow rate of 100 gallons per minute

Inverter Size Calculator [Power Inverter, AC, DC,

Feb 7, 2025 · Calculate the ideal inverter size with the Inverter Size Calculator. Perfect for selecting inverters for homes, solar panels, or vehicles based on

Choosing the Right Size and Capacity in Water Pump Inverters

6 days ago · These parameters will guide you towards a size and capacity that harmonizes with your requirements. Size Matters, Capacity Conquers. The size of the inverter directly

How to Select 3-Phase Solar Pump Inverter: A

Feb 27, 2024 · Dive into the essentials of selecting a 3-phase solar pump inverter with this guide, highlighting the different types, key applications, and critical

What Size Inverter Do I Need to Run a Sump

Aug 5, 2025 · But fear not! An inverter, they tell us, is the hero of this tale—a steadfast sentinel against the void. A ½ hp sump pump, my good sir, hums

What is a Water Pump Inverter and How Does It

6 days ago · The Water Pump Inverter is an innovative solution that redefines water pumping efficiency. Its ability to modulate electrical currents empowers

Solar Water Pump Sizing Calculator

Jul 12, 2024 · Solar Water Pump Sizing Calculator Daily Water Requirement (liters): Total Pumping Head (meters): Peak Sun Hours per Day: Calculate Imagine a world where the sun''s

How to Install a Solar Pump Inverter? | inverter

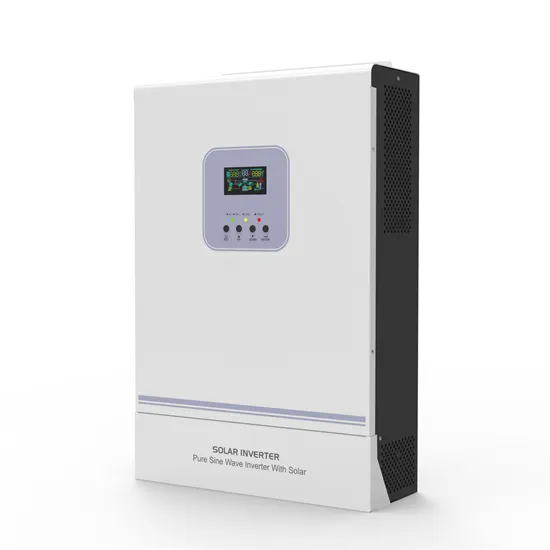

Aug 15, 2024 · The solar pump inverter is a device in the control part of the photovoltaic water pump (inverter + water pump). It forms a solar pumping system with photovoltaic cells and

How To Run Your Pool Pump Using Solar Power Like A Pro

Jul 5, 2024 · To run your pool pump on solar power, you need a solar panel, an inverter, and a battery bank. The solar panel collects energy from the sun, which is converted into electricity

How to optimize the operation of a water pump frequency inverter?

Jun 12, 2025 · Conclusion Optimizing the operation of a water pump frequency inverter is a multi-step process that involves selecting the right inverter, proper installation and commissioning,

What inverter size would run this well pump

Aug 30, 2023 · The fuse on my panel that is labelled ''water pump'' is a single 20 amp glass fuse, so I''m pretty sure it is 110/120 volt. I see a 4000 watt (8000 watt peak) inverter on Amazon

How to Choose a Water Pump Inverter Based on Pump Type

1 day ago · Choosing the correct water pump inverter is critical for optimizing pump performance, ensuring water availability, and reducing energy consumption. By considering the type of

Solar Water Pump Sizing Calculator

The Solar Water Pump Sizing Calculator is an essential tool for individuals who rely on solar power to pump water. By providing the required input data, users can accurately calculate the

What inverter size would run this well pump

Aug 30, 2023 · Never assume, measure it . You could be wired for 240vAC. However with this being a 1/2hp pump you should be able to power it with a 2000w inverter if the voltage is

How Can a Solar Pump Inverter Improve Your Water System

Jul 18, 2025 · Discover how a solar pump inverter enhances energy efficiency, reliability, and control in your water pumping system. Learn about key features, applications, and top

6 FAQs about [How big a water pump should I add to a 2kw inverter]

How do I choose the right inverter size for my pump?

When selecting an inverter size for the pump, it is important to choose one that can handle the startup power as well as the running power demanded by the pump. Inverters come in various sizes, typically measured in watts (W) or kilowatts (kW).

What size inverter do I Need?

To determine the appropriate size of the inverter needed to run a pump, it is necessary to calculate the power requirements of the pump. The power requirements can be calculated using the following formula: Power (Watts) = Voltage (Volts) x Current (Amps) First, you need to identify the voltage and current requirements of the pump.

Can a 1/2 HP water pump be wired with a 2000W inverter?

You could be wired for 240vAC. However with this being a 1/2hp pump you should be able to power it with a 2000w inverter if the voltage is correct. I power my 1/2hp 120vAC water pump with my 3000w (24vDC) without problems. But understand that not all 2000w inverters are equal.

Can a 1/2 HP water pump be powered with a 240 volt inverter?

Never assume, measure it . You could be wired for 240vAC. However with this being a 1/2hp pump you should be able to power it with a 2000w inverter if the voltage is correct. I power my 1/2hp 120vAC water pump with my 3000w (24vDC) without problems.

How many watts does an inverter need?

If you have a 1.5 HP pump, its running watts is going to be around 1500 watts, more or less. However, pump motors need a surge of power to start up. In a 1.5 AC pump this is about 3000 watts. Add 25% to 3000 watts and you get 3750 watts. Round that off to 4000, and that is the inverter you need.

Can a 500W inverter run a well pump?

As long as the inverter can handle the surge watts, you should be able to run the pump without trouble. Of course the rest of your solar system must be of sufficient size too. Does this mean you should get a 500W inverter? No, because the well pump still needs 3000 watts approximately during startup.

Learn More

- How big a photovoltaic inverter does a water pump need

- How big is the solar powered water pump

- How big a solar panel do I need for a 6w water pump

- How big an inverter is needed for a 1 000W solar panel

- How big an inverter should I use for a 60v power supply

- How big a grid-connected box should I use for a 15kw inverter

- Three-phase water pump inverter manufacturer

- How much does a solar circulating water pump q200 cost

- How big an inverter can a 24v40a battery use

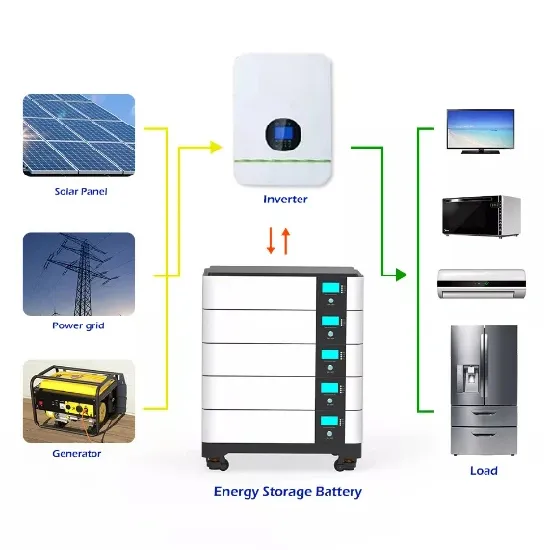

Industrial & Commercial Energy Storage Market Growth

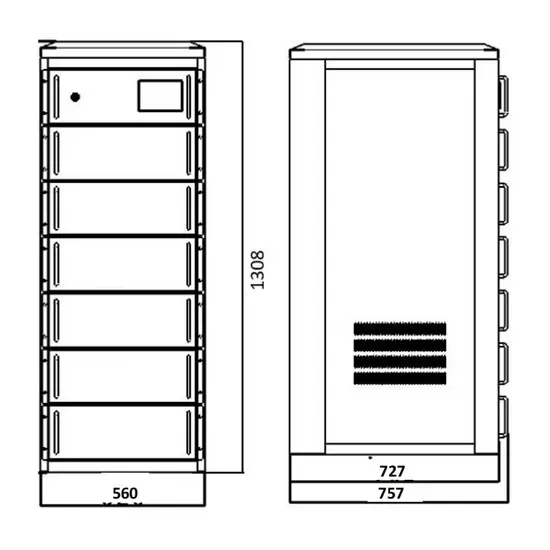

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.