Photovoltaic solar power generation counterweight pier

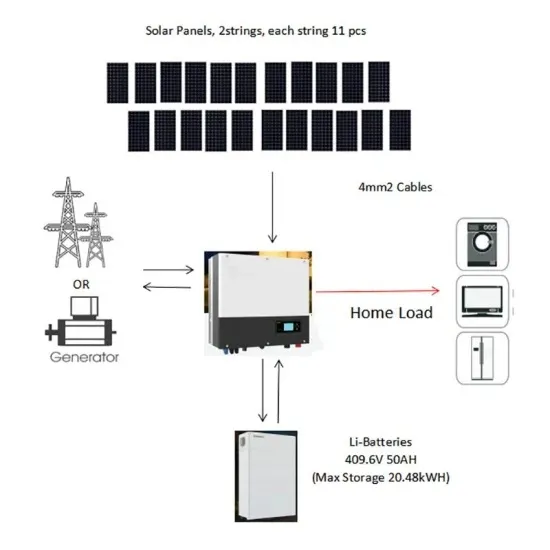

The solar power plant uses solar energy to produce electrical power. Therefore, it is a conventional power plant. Solar energy can be used directly to produce electrical energy using

Photovoltaic support concrete block counterweight method

Seismic Design Considerations for the Installation of Photovoltaic Support structures for solar panels can be installed with anchor bolts directly to the slab or by applying extra weight to the

Design and performance analysis of a solar tracking system

Apr 15, 2020 · The increase in environmental pollution caused by fossil fuels and the growing emphasis on energy diversity highlight the need for solar energy all over the world [1], [2], [3].

Calculation of photovoltaic panel counterweight

May 6, 2022 · As the photovoltaic (PV) industry continues to evolve, advancements in Calculation of photovoltaic panel counterweight have become critical to optimizing the utilization of

Optimization of Photovoltaic Panel Array Configurations to

Aerodynamic lift force acting on the solar structure is important while designing the counterweight for rooftop-mounted solar systems. Due to their unique configuration, the load estimated for

PHOTOVOLTAIC PANELS SOLAR POWER GENERATION COUNTERWEIGHT

China s solar photovoltaic power generation area is the largest market in the world for both and . China''s photovoltaic industry began by making panels for, and transitioned to the manufacture

Definition of photovoltaic support counterweight

What is a photovoltaic mounting system? Photovoltaic mounting systems (also called solar module racking) are used to fix solar panels on surfaces like roofs,building facades,or the

Photovoltaic bracket-SHIWEI NEW ENERGY

Photovoltaic bracket Photovoltaic support, also known as solar panel support, is an important equipment used to install and support solar panels in solar photovoltaic power generation

Design example of photovoltaic support counterweight

load capacity,and adaptability to complex terrain Should a rooftop solar panel have a counterweight? with a counterweight to hold the structure in place. Counterweight costs are a

Photovoltaic support counterweight installation standards

The foremost requirement is the structural strength of the roof, which should be capable of supporting the additional weight of the solar panels and the mounting structure. The solar

Photovoltaic panel counterweight

Standard residential solar panels contain 60 solar cells (or 120 half-cut solar cells) and typically generate anywhere from 350W to 500W of electricity. The size of these panels can range from

Photovoltaic support counterweight leveling method

Slope leveling is essential for the successful implementation of ground-mounted centralized photovoltaic (PV) plants, but currently, there is a lack of optimization methods This paper

Photovoltaic panel counterweight fixing method

About Photovoltaic panel counterweight fixing method As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic panel counterweight fixing method have become

Design specification of photovoltaic support

In the photovoltaic (PV) solar power plant projects, PV solar panel (SP) support structure is one of the main elements and limited numerical studies exist on PVSP ground mounting steel frames

Assessment of solar tracking systems: A comprehensive review

Aug 1, 2024 · Implementing solar tracking systems is a crucial approach to enhance solar panel efficiency amid the energy crisis and renewable energy transition. Th

How to move the photovoltaic panel counterweight

About How to move the photovoltaic panel counterweight Passive tracking devices use natural heat from the sun to move panels. Active tracking devices adjust solar panels by evaluating

New counterweight for photovoltaic bracket

A photovoltaic bracket is a bracket, such as a solar photovoltaic bracket, which is a special bracket designed for placing, installing and fixing solar panels in a solar photovoltaic power

New counterweight for photovoltaic bracket

What is a photovoltaic mounting system? Photovoltaic mounting systems (also called solar module racking) are used to fix solar panels on surfaces like roofs,building facades,or the

Solar power generation counterweight factory

The folding photovoltaic power generation structure with the counterweight comprises a base plate and a telescopic cylinder; the upper plate surface of the base plate is vertically provided

How to move the photovoltaic panel counterweight

Solar Panels; The solar panels, typically mounted on the vehicle''''s surface, consist of multiple interconnected PV cells. These panels are designed to capture and convert sunlight into

Photovoltaic Support Counterweight Design Atlas: The

The answer often lies in their photovoltaic support counterweight design atlas - the unsung hero of solar energy systems. Let''s dig into this crucial yet overlooked aspect of solar engineering

Solar power generation counterweight factory

Should a rooftop solar panel have a counterweight? Conclusions Most residential and commercial rooftops are flat,which are the simplest for mounting solar panels with a counterweight to hold

Ballasts for solar panels: from 0° to 30°, the right

Jan 22, 2025 · The most suitable tilt for a photovoltaic system on a flat roof depends on numerous factors, and thanks to its wide range of models, Sun

Photovoltaic bracket counterweight bar foundation

This case study focuses on the design of a ground mounted PV solar panel foundation using the engineering software program spMats. The selected solar panel is known as Top-of-Pole

Photovoltaic panel counterweight pier manufacturing process

Optimization of Photovoltaic Panel Array Aerodynamic lift force acting on the solar structure is important while designing the counterweight for rooftop-mounted solar systems. Due to their

Photovoltaic panels Solar power generation counterweight

Concentrated Solar Power (CSP) Vs Photovoltaic (PV): An In CSP is an indirect method that generates alternating current (AC), which will then be easy to distribute on the power network.

6 FAQs about [Solar photovoltaic panel counterweight]

Should a rooftop solar panel have a counterweight?

Conclusions Most residential and commercial rooftops are flat, which are the simplest for mounting solar panels with a counterweight to hold the structure in place. Counterweight costs are a significant portion of the overall PV plant’s cost and must be optimized to get a levelized cost of energy production.

Do solar photovoltaic plants need a support structure?

Solar photovoltaic plants installed on rooftops require a support structure to keep these structures in place against wind loading. This support structure is usually a concrete counterweight. The cost of this concrete counterweight is a significant portion of the overall plant cost.

What is the performance ratio of a 1MW grid-connected photovoltaic system?

Sharma et al. analyzed the performance ratio of a 1MW grid-connected photovoltaic system installed in Rajasthan (India) for one year and found that the average performance ratio for the plant was 0.79 for the simulation carried out using Pvsyst, while the performance ratio for the actual project data was 0.78.

How to optimize the lift force on solar panels?

Proposed Methodology A novel methodology is proposed that combines the performance ratio with the optimization method (Genetic Algorithm) and CFD to optimize the lift force on the solar panel arrays by considering the tilt angle andpitch between rows to reduce the counterweight onthe pre-fabricated roofs.

How to optimize solar photovoltaic strings?

Many optimization methods are used, such asthe Genetic Algorithm, response surface method, ant colony method, etc. Nagadurga et al. used a chip optimization algorithm to enhancethe global maximum power point of solar photovoltaic strings under partial shading conditions.

Can solar panels reduce wind load?

This research was carried out to find an optimum configuration in which the PV plants could be designed to reduce the impact of wind loading and thus reducethe counterweight required for roof-mounted solar systems. Wind loading can be estimated to a good extent with the help of Computational Fluid Dynamics.

Learn More

- Photovoltaic solar panel field development

- 35v solar photovoltaic panel

- 30 volt solar photovoltaic panel

- Where are the photovoltaic solar panel companies located

- Which type of monocrystalline solar photovoltaic panel is better

- Solar photovoltaic panel arrangement

- Photovoltaic solar panel installation in Montenegro

- Portugal Solar Panel Photovoltaic Power Generation Project

- Middle East soft solar photovoltaic panel manufacturers export

Industrial & Commercial Energy Storage Market Growth

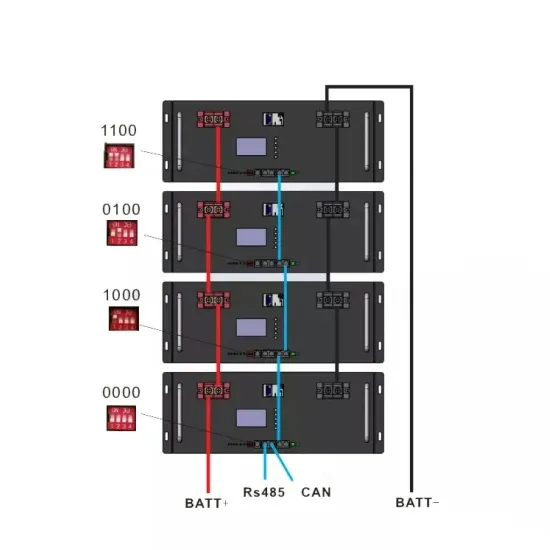

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

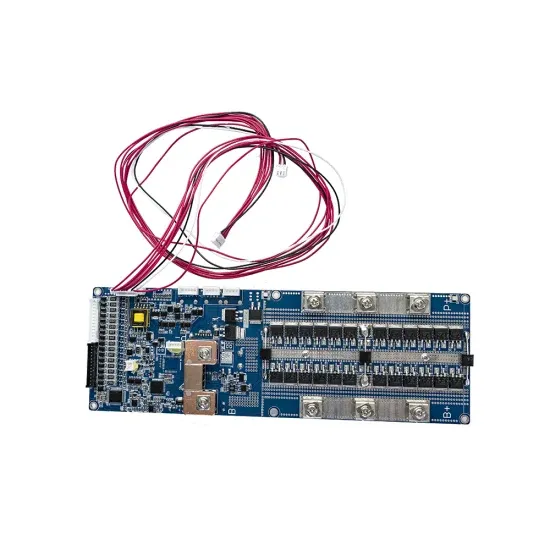

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.