Spatial layout optimization for solar photovoltaic (PV) panel

May 1, 2020 · Layout design maximizes the energy production potential of a solar PV system. The new method has been applied to identify the optimal panel layout on a rooftop. Flexible panel

How to arrange solar panel components | NenPower

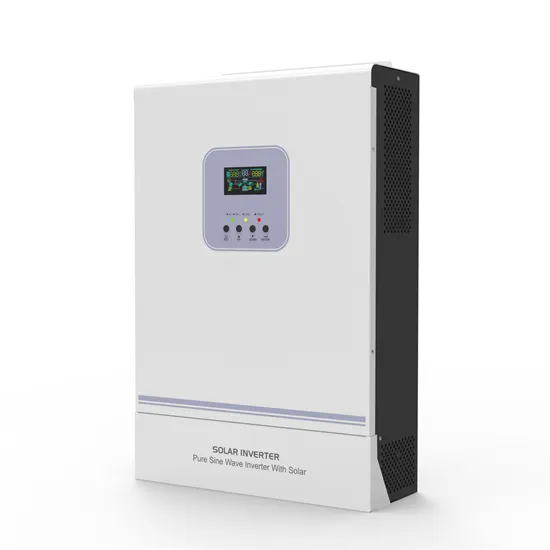

Apr 20, 2024 · The primary components of a solar panel system include photovoltaic panels, inverters, battery storage systems, and mounting hardware. Photovoltaic panels are

Photovoltaic panel arrangement and leveling diagram

Calculate the photovoltaic array size by estimating the daily energy demand,factoring system efficiency,and using location-specific solar irradiance data to determine how many solar panels

Solar photovoltaic system design optimization by shading analysis

Mar 11, 2016 · The number of solar panels can be maximized in a solar photovoltaic energy generation system by optimizing installation parameters such as tilt angle, pitch, gain factor,

Novel approaches to optimize the layouts of solar photovoltaic

Feb 1, 2025 · A schematic illustrating the arrangement of solar panels and wind turbines. (left) PV panels display variations in GCRs and tilt angles, (right) simple distribution of rows and

The Ultimate Guide to Optimal Solar Panel Placement

Aug 31, 2024 · When panels are aligned correctly to face the sun, they optimize the amount of solar radiation that reaches the surface and absorb solar energy. Because of their perfect

Photovoltaic (PV) Module and Its Panel and Array

Nov 10, 2023 · The arrangement of solar cell, packing factor, semi-transparent and opaque PV module, and its basic parameters, namely fill factor, maximum power, and electrical efficiency

Analysis of Different Solar Panel Arrangements using

Sep 10, 2022 · Here we were using a single layer panel, a single layer panel with tracking system and a three layer solar PV panel arrangement with solar tracking for comparison.

Optimize Solar Panel Placement for Peak Performance

Jun 27, 2024 · Learn the best strategies for solar panel placement to boost efficiency and energy output. Explore expert tips on orientation, tilt angles, and installation for maximum savings.

Installation of Solar PV Systems

May 19, 2020 · 6.6.1 The Solar PV System designers and installer should cater for the installation of suitable instruments and make adequate arrangements to remote monitor the performance

CFD simulations for layout optimal design for ground

Nov 1, 2023 · Photovoltaic (PV) power plants play an important role in regulating regional energy structures and reducing carbon emissions. The existence of PV power plants also alters the

Analysis of Different Solar Panel Arrangements using

Mar 7, 2022 · Here, three different arrangements of solar PV modules are done on a standalone system. In this work, the maximum generation was obtained from a three layer solar PV

Numerical study on the sensitivity of photovoltaic panels to

Sep 1, 2024 · The arrangement of array b that is less sensitive to wind direction, less lifting torque and relatively small pressure distribution on the surface of the photovoltaic panel, which is a

PV System Design – How to Arrange Solar Panels for

Feb 6, 2025 · Proper arrangement ensures the highest possible energy yield, allowing homeowners and businesses to get the most out of their investment. An optimized PV system

6 FAQs about [Solar photovoltaic panel arrangement]

How solar panels are arranged in a single layer solar PV system?

So the arrangement of solar PV modules are a major concern to meet the demand of the consumer. Single layer solar PV system Three solar panels are arranged in a single layer with a tilt of 130. Each panels are arranged without affecting the partial shading issues. The panels are facing towards the south pole.

What is a solar cell arrangement?

A solar cell arrangement is known as solar module or solar panel where solar panel arrangement is known as photovoltaic array. It is important to note that with the increase in series and parallel connection of modules the power of the modules also gets added. Related Posts:

How to arrange solar modules in a photovoltaic power station?

There are two ways of arranging solar modules in photovoltaic power stations, horizontal and vertical. Horizontal means that the long side of the solar module is parallel to the east-west direction, while vertical means that the short side is parallel to the east-west direction. Whether to use horizontal or vertical depends on different situations.

How a three layer solar PV panel is connected with solar tracking system?

For obtaining maximum energy, panels are separately connected with solar tracking systems. Panels are facing towards the east pole direction. Fig.5 shows the 3D arrangement of a three layer solar PV panels with solar tracking system. Fig.6 shows the front view of a three layer solar PV panel incorporated with solar tracking system.

How can GIS Help A solar PV system?

GIS finds the suitable areas for solar PV panel installation. Layout design maximizes the energy production potential of a solar PV system. The new method has been applied to identify the optimal panel layout on a rooftop. Flexible panel alignments increase the maximal energy production by up to 6%.

How PV panels are connected in series configuration?

The following figure shows PV panels connected in series configuration. With this series connection, not only the voltage but also the power generated by the module also increases. To achieve this the negative terminal of one module is connected to the positive terminal of the other module.

Learn More

- Lithuanian thin film solar photovoltaic panel manufacturer

- Romania Solar Panel Photovoltaic

- A solar photovoltaic panel costs 49 yuan

- Photovoltaic solar panel 1

- Polycrystalline silicon solar photovoltaic panel 1080x808

- Double-glass photovoltaic panel solar module

- Solar photovoltaic panel 6v35w

- Solar Photovoltaic Panel Currency

- Lithuanian solar photovoltaic panel manufacturers

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.