Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

PDU8000 电池柜-T 快速指南 (02405362)

Jun 18, 2019 · 本文档主要介绍电池柜安装和调试的操作方法。2 Tools / 安装工具 4 Installing a Battery Cabinet / 安装电池柜 PDU8000 Battery Cabinet-T Quick Guide 4.1 Checking Before

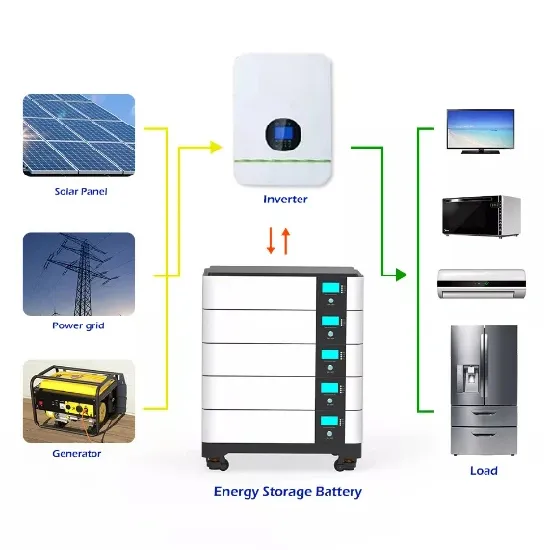

Operation of Energy Storage Battery Cabinets on the Grid Side

Aug 24, 2024 · Energy storage battery cabinets are integral components of energy storage systems. Their operation on the grid side involves energy charge/discharge management,

How to Install a Lithium Battery System Safely and Efficiently?

Apr 11, 2025 · Installing a lithium battery system is a critical process that demands attention to safety protocols, proper tools, and environmental considerations. Whether integrating with

User''s and installation guide

Mar 9, 2021 · Read this document before you start to operate or perform work on the UPS system. This document contains important instructions that must be followed during the installation,

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Refer to "Securing the Batteries Using the Battery Retention Strap" on page 21 for instructions on securing the batteries using the buckle strap provided with the battery cabinet.

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Installation and Owner''s Manual

Mar 10, 2025 · Introduction This installation manual provides instructions and recommendations for installing and commissioning the Generac PWRcell® Battery. The PWRcell Battery is

GRID CONNECTED PV SYSTEMS WITH BATTERY ENERGY

May 22, 2023 · The term battery system replaces the term battery to allow for the fact that the battery system could include the energy storage plus other associated components. For

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Procedure Refer to Figure 3 and install the 19" or 23" relay rack mounting angles to the battery cabinet. Mounting hardware is provided with the battery cabinet. Torque these

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · VDC battery cabinet can be mounted in a 23" relay rack or mounted to a wall. The battery cabinet contains one (1) 40 A battery disconnect circuit binets may be daisy chained as

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Put the new battery into place. Make sure new battery is installed properly regarding polarity orie ation. Use the supplied wiring drawing found inside the battery cabinet door to ver

Battery cabinet

Mar 16, 2024 · For a correct installation and cabling of the battery cabinet, please follow step by step the instructions described below The instructions refer to the installation of the maximum

What are the standard requirements for battery

Jun 2, 2024 · Adhering to various regulatory standards is vital for ensuring that battery energy storage cabinets operate within legal and safety frameworks.

ZincFive BC Series UPS Battery Cabinets

Jun 9, 2023 · Safety Safety Symbols ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used

USER MANUAL BATTERY CABINET

Jul 28, 2025 · Before installing, operating, or maintaining the system, it is important to inspect all existing wiring to ensure it meets the appropriate specifications and conditions for use. Ensure

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · 1 Introduction During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load.

Eaton 9390 IDC (100-160 kVA) installation and operation

Aug 19, 2024 · 2.2 Preparing the Site For the IDC to operate at peak efficiency, the installation site should meet the environmental parameters outlined in this manual. If the IDC is to be

BC Series UPS Battery Cabinets

Jan 23, 2024 · Safety Symbols ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used properly. To

6 FAQs about [How to operate the battery cabinet site]

How do I connect a battery cabinet to a power system?

Procedure 1. Furnished with the battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabinet battery disconnect circuit breaker alarm into the power system alarm circuits.

What is included in the Battery Cabinet Manual?

This manual contains important instructions that should be followed during installation and operation of the battery cabinet. This product is designed for commercial / industrial use only, with UPS systems. It is not intended for use with life support and other designated critical devices.

How do I install a VDC battery cabinet?

Set first battery in cabinet and attach the long lead (fast-on connector side marked positive) from the cabinet to the fast-on terminal on the positive terminal of the battery. See Figure 24. Facing left Facing right Facing left Vertiv™ NetSure™ 211 SERIES -48 VDC Battery Cabinet Installation & User Manual (Section 6023) Rev. L 23 Figure 24:

How do you put a 4th Battery in a cabinet?

Place another inner battery spacer next to the third battery. 9. Set fourth battery in cabinet (being careful of the door fastener tabs hanging down) and attach the other end of the fast-on lugged cable to the negative terminal on the third battery (fast-on terminal).

How many battery cabinets can be connected together?

The battery cabinet is designed to be daisy-chained together with additional battery cabinets. There is no limit to the number of battery cabinets that can be connected together. However, a maximum system current of 30 A should be maintained regardless of the number of interconnected battery cabinets. Procedure NOTE! Refer to Figure 7

What to do if a battery cabinet is damaged?

In case of damage, notify immediately the carrier. The packing container of the battery cabinet protects it from mechanical and environmental damage. Preserve the packaging for later re-use. Refer in each moment to the electrical scheme at section 3.

Learn More

- How to start the site energy battery cabinet

- How to view distributed power generation at the battery exchange cabinet site

- What are the components of the battery cabinet Site cabinet

- How to check the battery photovoltaic of the energy storage cabinet

- How is the battery technology of photovoltaic energy storage cabinet

- Centralized battery cabinet installation site

- How to make power cord for battery cabinet

- How much does it cost to install a battery cabinet in Port Vila

- Energy Storage Battery Cabinet Design Method Site

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.