Cord for easy power switching a fridge between mains and portable power

Dec 17, 2021 · After the Public Safety Power Shutoffs and regular blackouts in my area, I purchased a solar generator (think a suitcase battery with hookups for small solar panels).

How to connect the power cord of the energy storage

Jan 28, 2023 · The power leads must be connected to the lower left and the lower right terminals of the terminal block. DO NOT remove the ground strap connection. FOR POWER CORD

Installation, connection and sizing of cables with UPS

Jun 22, 2022 · Calculation of currents I1, Iu The input current Iu from the power network is the load current The input current I1 of the charger/rectifier depends on: The capacity of the

UPS Battery Cabinet Upgrade, Retrofit, Replacement

5 days ago · Whether leveraging an existing cabinet through a like-for-like replacement or opting for a new UPS battery cabinet or rack altogether, you''ll need to consider connector

Can I run an electric power cord or extension

Feb 10, 2019 · Cords are allowed to connect to a receptacle in a "space adjacent to the space occupied by the appliance." So a cord can go through a cabinet

DIY Battery Station – Build a Battery Charging Station

This station is perfect for holding all of your cordless tool battery chargers. What sets it apart from a simple shelf is the concealed chase for routing and hiding the power cords for a nice clean

DIY Mobile Battery Charging Station for Workshop

Aug 13, 2022 · In this post, I''m sharing how to build a DIY mobile battery charging station for your workshop or garage! Cordless tools are a game changer. Butthose batteries can accumulate

11 Creative Ways to Hide Electrical Cords That

6 days ago · Strategic Furniture Placement Arrange bookcases filing cabinets or console tables along walls where outlets are located to naturally shield power

6 FAQs about [How to make power cord for battery cabinet]

How do I make new battery cables?

Making new battery cables isn't difficult, however, and you won't need complex machinery to do it. Lift the hood and check the battery, as well as all connected lines and cables, for rust, corrosion or bad connections. Before making new cables, check which ones actually need to be replaced.

How do you connect a battery charger to a door?

Add each of the chargers to the door and route the wires inside. Plug in each of the wires into the power strip and tie up any extra wire using velcro cord organizers. For the smaller chargers that have a large plug, I placed them on the top shelf and plugged them into the power strip.

How do you put a charger cord in a shelf?

Route the cords through the holes in the shelf and then through the hole in the bottom. It is a good idea to mark each cord near the plug with a label to prevent confusion later. You can hide excess cord in the chase or wrapped up behind the charger.

What is a cordless tool battery charger station?

This station is perfect for holding all of your cordless tool battery chargers. What sets it apart from a simple shelf is the concealed chase for routing and hiding the power cords for a nice clean look. This is a very simple project made from just a quarter sheet of plywood and a few screws.

How do you cut a battery cable?

You can use your terminal lugs (the piece that attached to the battery) to estimate how much you should cut away. Simply line it up with the cable and note how long the hole is, then cut away enough rubber so that the actual metal cable fits in snugly. Don't worry if you cut too much away -- you will be re-sheathing the cables later.

How do you mount a Ryobi charger to a wall?

In fact, the Ryobi charger was so close to the top that I just sent the wire in over the top. Make a hole in the side of the cabinet. This is where the power strip plug will exit to be plugged into the wall. There are multiple ways you can mount the charging station to the wall: Use a screw through the back into a stud. Using a French cleat.

Learn More

- How to connect the signal base station battery to the power distribution cabinet

- How to calculate power and current in battery cabinet

- How to make a good brand of battery cabinet

- How much power does the battery cabinet have in total

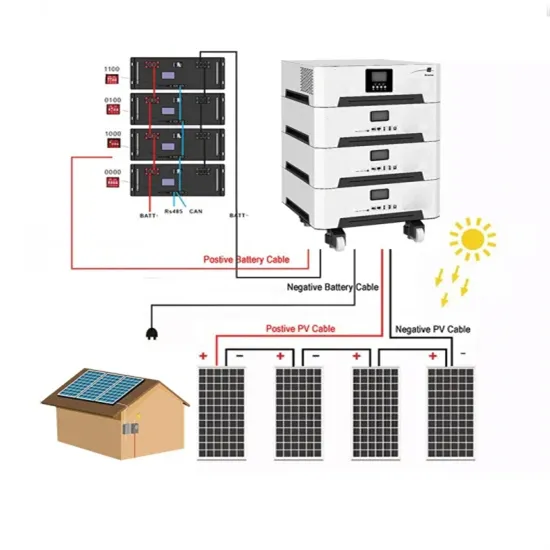

- How to change the lithium battery station cabinet to photovoltaic power supply

- How to calculate the specifications of battery cabinet and power storage cabinet

- New Energy Battery Cabinet Power Cord Production

- Battery cabinet battery wind power box base station

- The battery with the largest power in the energy storage cabinet

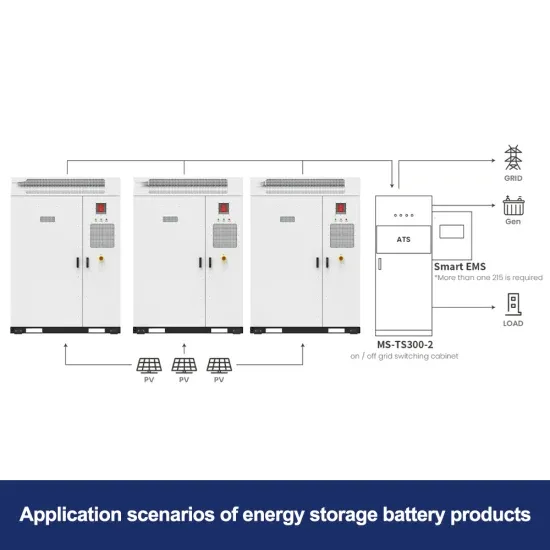

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.