Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an

Frequency inverters from EMA Indutec GmbH

Each IGBT inverter has its own digital controller. Their numerous integrated interfaces allow connection to current bus systems, control systems and other components. The EMA Indutec

Two-stage grid-connected inverter topology with high frequency

Nov 1, 2023 · These recent studies have contributed to the understanding and advancement of two-stage grid-connected inverter topologies with high-frequency link transformers, providing

GSO GSA Series: Efficient Solar Inverter Control Integrated

GSO Company''s GSA Series Photovoltaic Inverter Control Integrated Machine, with its efficient, intelligent, and reliable characteristics, stands out in the new energy field.

An integrated controller for high‐frequency LCLC resonant inverter

May 19, 2016 · A feasible implementation of high-frequency power source is examined by a full-bridge LCLC resonant inverter. The corresponding control scheme is proposed for the fourth

Frequency inverters from EMA Indutec GmbH

A standardized control component for all frequency and power ranges Inverters from our own production – everything from a single source! Inverter with several separately controllable

36V 50A Three-Phase GaN Inverter Reference Design for

Jul 21, 2025 · Description This design guide demonstrates a 36V, 50A gallium nitride (GaN), field-effect transistor (FET) power stage for driving a three-phase brushless DC motor in cordless

Hybrid compatible grid forming inverters with coordinated

Aug 16, 2025 · In this context, this paper proposes a comprehensive control and system-level realization of Hybrid-Compatible Grid-Forming Inverters (HC-GFIs)- a novel inverter framework

An integrated controller for high‐frequency LCLC

May 19, 2016 · An integrated control scheme is proposed for the fourth-order resonant inverter to handle the control challenges of low output harmonics and

An integrated controller for high-frequency LCLC resonant inverter

Jan 1, 2016 · Secondly, an integrated control scheme is presented to implement pulse-width control at heavy load and frequency regulation at light load.

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · dc–ac converter 29 High-Frequency Inverters, the HF transformer is incorporated into the integrated structure. In the subsequent sections, based on HF architectures, we

Design of High-frequency, Load-independent Resonant Inverter

Mar 23, 2023 · This paper presents a phase-control method in paralleled resonant inverters to provide constant output power independent of load variation at MHz frequencies. A single

Improving frequency stability in grid-forming inverters with

May 13, 2025 · The increasing utilization of renewable energy sources in low-inertia power systems demands advanced control strategies for grid-forming inverters (GFMs).

A High Performance High Frequency Inverter Architecture

Oct 14, 2021 · In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

An integrated controller for high-frequency LCLC resonant inverter

Jan 1, 2017 · An integrated controller for high-frequency LCLC resonant inverter with phase-shifted control and frequency regulation | International Journal of Circuit Theory and Applications

An integrated controller for high‐frequency LCLC resonant inverter

May 19, 2016 · An integrated control scheme is proposed for the fourth-order resonant inverter to handle the control challenges of low output harmonics and dynamic nonlinear load. First, an

A New Architecture for High-Frequency Variable-Load

Dec 4, 2023 · This paper introduces a new inverter architecture and control approach that directly addresses this challenge, enabling radio-frequency power delivery into widely variable loads

High frequency off-grid inverter control

Dec 7, 2024 · This article delves into the intricacies of high-frequency off-grid inverter control systems, exploring their key components, operating principles,

Improved two-stage boost inverter with integrated control

May 15, 2019 · Abstract In this study, an integrated control strategy is proposed which can be widely used in two-stage boost inverters, and an improved two-stage boost inverter is taken as

Efficient Boost Integrated High Frequency Inverter based

Oct 9, 2024 · Conventional IC-based transportation is replaced by modern electric vehicle EVs to limit Greenhouse gas emissions (GHG). However, EV charging is completely dependent on

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · A comprehensive analysis of high-power multilevel inverter topologies within solar PV systems is presented herein. Subsequently, an exhaustive examination of the control

Buck–Boost Dual-Leg-Integrated Step-Up Inverter With Low

Aug 21, 2017 · To support the development of high-frequency ac microgrids in terms of compact design, high-voltage gain and low total harmonic distortion (THD), a buck-boost dual-leg

48-V, 10-A, High-Frequency PWM, 3-Phase GaN Inverter

Apr 3, 2017 · Low-voltage, high-speed drives and low-inductance brushless motors require higher inverter switching frequencies in the range of 40 kHz to 100 kHz to minimize losses and torque

High Frequency Three-Phase CRM Inverter with Integrated

Oct 24, 2024 · This paper presents the design of a 30kW wide-band-gap (WBG) device based 3-phase inverter for auxiliary power supplies (APS) in railway applications. The critical

Inverse control integrated high-frequency machine

Jul 30, 2025 · The all-in-one high-frequency inverter-controller integrates a high-frequency inverter and MPPT-based charge/discharge controller into a single compact unit. Its modular and

6 FAQs about [High frequency inverter with integrated inverter control]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

Can inverters provide efficient delivery of high-frequency power into variable load impedances?

VI. CONCLUSION This paper introduces an inverter architecture and associated control approach for providing efficient delivery of high-frequency power into variable load impedances while maintaining resistive/inductive loading of the constituent inverters for ZVS soft switching.

Which type of inverter is suitable for HF operation?

In practice, one can utilize any type inverter suitable for HF operation under resistive/inductive loading; amplitude control of the individual inverters can be realized through any suitable means (e.g., supply voltage modulation, phase-shift or outphasing control, pulse-width modulation, etc.).

Which power supply topologies are suitable for a high frequency inverter?

The power supply topologies suitable for the High-Frequency Inverter includes push-pull, half-bridge and the full-bridge converter as the core operation occurs in both the quadrants, thereby, increasing the power handling capability to twice of that of the converters operating in single quadrant (forward and flyback converter).

How do HF inverters work?

Inverter designs at HF generally utilize fundamental-frequency inductive loading of the inverter transistor(s) to achieve the zero-voltage switching transitions necessary for high efficiency.

Why are HF inverters so expensive?

Abstract—Efficient generation and delivery of high-frequency (HF, 3-30 MHz) power into variable load impedances is difficult, resulting in HF inverter (or power amplifier) systems that are bulky, expensive and inefficient.

Learn More

- 1kW high frequency inverter power consumption

- Macedonia high frequency inverter equipment

- Industrial frequency high frequency low frequency inverter

- High frequency resonant inverter

- High frequency chopper inverter

- High frequency machine to inverter

- Power frequency solar off-grid inverter high power

- High frequency inverter has low frequency

- High frequency isolated energy storage inverter

Industrial & Commercial Energy Storage Market Growth

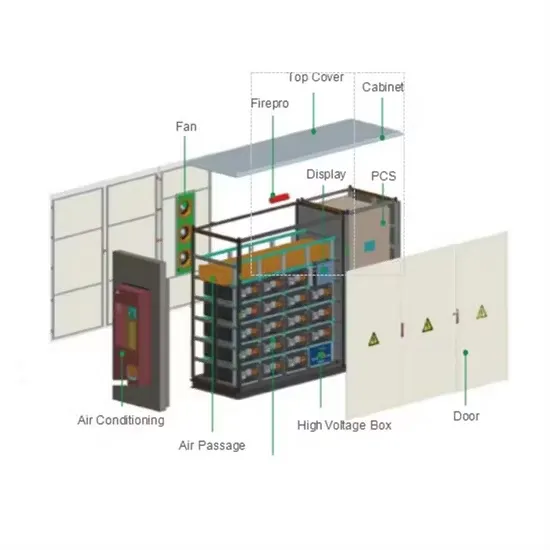

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.