Shipping Container Insulation Guide | Stay Comfortable in

Jul 22, 2025 · Learn how to insulate a shipping container for living, storage, or office use. Discover the best materials, methods, and tips to improve comfort, energy efficiency, and temperature

Energy Storage Safety Systems Explosion Vents for BESS

Aug 7, 2025 · Explosion Venting Protection for Battery Energy Storage Systems -SafTM explosion vents for Battery Ene Vent-Saf explosion vents are usually installed on the roof of BESS

How to Insulate a Shipping Container from Heat

Jun 8, 2022 · It''s vital to know what each type of insulation option offers you when you consider how to insulate a shipping container. Choose from Styrofoam,

Energy efficiency on the reefer container storage yard; an

Feb 1, 2020 · In this paper aim to simulate a thermal simulation using computational fluid dynamic (CFD) concerning the effect of roof shade over storage yard in reefer container storage yard.

Storage Container Insulation Types: What''s Right for Your

Jun 25, 2025 · To achieve these results, two of the most widely used insulation options are spray foam and fiberglass batt. Each of these options has distinct advantages and considerations

Container energy storage thermal insulation materials

Container heat insulation and fire protection design refers to designing a set of heat insulation and fire protection system inside the container to protect the goods in the container from the

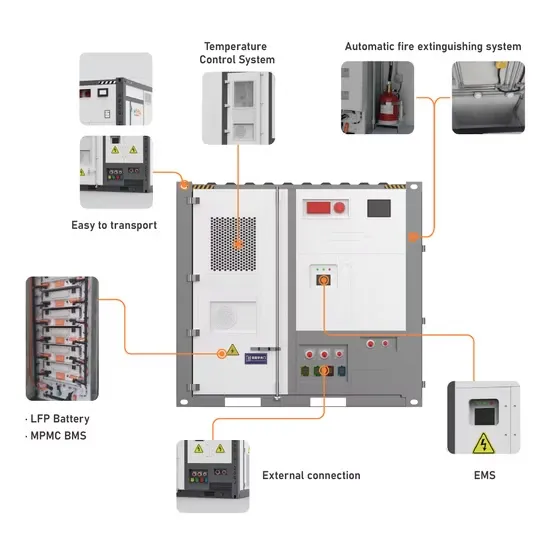

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

Energy storage container roof insulation

oam: Ideal for Basic Storage Containers. Fast and easy to install, polystyrene (commonly known by one brand name, Styrofoam) is a cost-effective way to add basic insulation to a storage

Energy Storage Insulation Material: A Game-Changer for a

Energy storage insulation material is designed to insulate buildings, systems, and devices while simultaneously storing energy. By combining both insulation and energy storage properties,

FIRE AND EXPLOSION PROTECTION FOR BESS

Jan 9, 2024 · Battery Energy Storage Systems (BESS) have become, in a few years, an unparalleled solution to remedy the intermittency of certain renewable energies, such as wind

Spray foam insulation to the roof of a shipping

Apr 11, 2024 · By insulating the container roof, we''ve significantly improved its thermal efficiency and weather resistance, making it suitable for a variety of

Storage Container Insulation: Essential Guide for Optimal

Dec 16, 2023 · Additional benefits include noise reduction ideal if your storage container doubles as work space and increased structural integrity of the unit itself; thanks to insulation acting as

Sustainable Double Membrane Roofs for Renewable Energy

Double membrane roofs consist of two layers of material—typically high-quality, durable membranes—that are inflated to create an airtight space between them. This space, known as

Tank Insulation | Industrial Storage Tank | nVent RAYCHEM

4 days ago · Industrial tank insulation systems reduce the amount of heat lost or gained, keeping stored liquids at a constant temperature while minimizing energy usage. Typical applications

Essential Design Features for a High-Performance BESS Container

Nov 27, 2024 · Discover the top 8 functional design considerations for Battery Energy Storage System (BESS) container enclosures, focusing on safety, durability, thermal control, and ease

Best Shipping Container Insulation: Keep Your

Jul 25, 2024 · Discover the best shipping container insulation solutions to regulate temperature, prevent moisture buildup, and enhance energy efficiency. Learn

6 FAQs about [Energy storage container roof insulation]

What is container heat insulation & fire protection design?

Operator Safety: Ensure operator safety by addressing factors such as adequate lighting and ventilation systems within the container. Container heat insulation and fire protection design is a multifaceted endeavor, requiring a holistic approach to factors like insulation, fire protection, fire prevention systems, and operator safety.

What is shipping container insulation?

The primary function of insulation is to control the level of temperature, prevent moisture, and maintain a stable environment without compromising interior space. There are several types of shipping container insulation to review when you choose material for your home.

What is the best insulation for a shipping container?

One of the more costly but highly sustainable options for insulation is denim or cotton materials. This shipping container insulation is created from recycled jeans, clothing, and cotton-based items, which is excellent for minimizing waste.

Can you use foam spray insulation in a shipping container home?

The type of foam spray insulation you apply in your shipping container home depends on the climate, geographical area, and what works best for the type of materials you currently use in your home. You’ll find many inexpensive options that are highly effective and long-lasting with excellent results.

Why is a shipping container insulated?

Insulation is an important material that is required in every building or structure. It provides protection from external elements, such as cold, wind, moisture, and heat. Shipping containers are typically constructed out of metal, creating a considerable amount of condensation and heat during the summer.

How much does it cost to insulate a shipping container?

Generally, the cost to insulate your shipping container depends on the materials, the size of your container, how many containers you plan to insulate, and whether you install on your own or hire a contractor. On average, a 20-foot container starts around $2,000, or $4,000 for a 40-footer, and can increase from this point.

Learn More

- Tplink outdoor energy storage container base station

- Manama container energy storage fire fighting system base station

- Container battery energy storage manufacturers ranking

- Energy Storage Container Mining Bureau Solar Power Generation

- Energy storage container booster cabin

- Energy storage container assembly line base station power generation

- Energy storage container in Antwerp Belgium

- St George energy storage explosion-proof container wholesale

- Energy Storage Container Electrical and Energy Storage

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

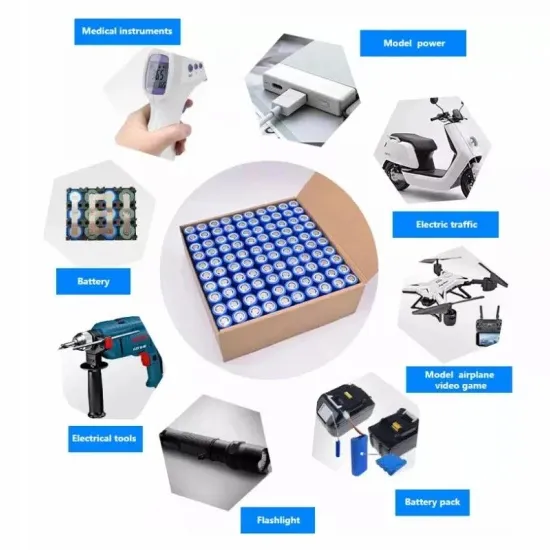

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.