Optimal configuration of 5G base station energy storage

Feb 1, 2022 · A multi-base station cooperative system composed of 5G acer stations was considered as the research object, and the outer goal was to maximize the net profit over the

Assembly Line for Battery Energy Storage System (BESS)

Maestrotech''s BESS assembly lines optimize the production of energy storage units with advanced automation and high precision. Designed for precise prismatic cell sorting, these

Energy Storage Assembly Line: The Backbone of Modern Power

Jun 18, 2020 · Welcome to the world of the energy storage assembly line —the unsung hero behind everything from electric vehicles to grid-scale power storage. With global demand for

Systems Development and Integration: Energy Storage and Power Generation

Aug 13, 2025 · Systems development and integration projects help to enable the production, storage, and transport of low-cost clean hydrogen from intermittent and curtailed renewable

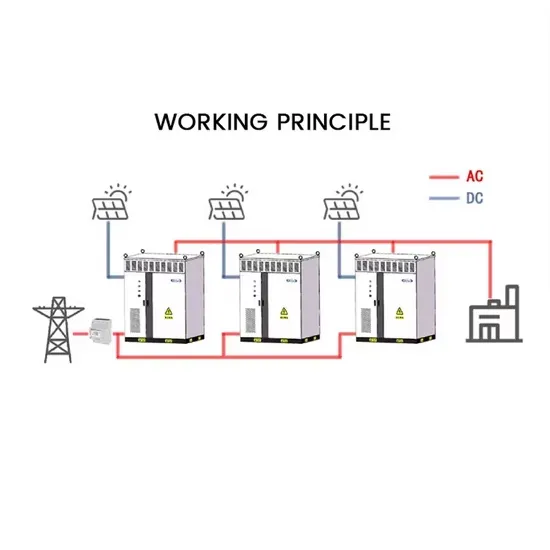

Huijue Group was founded in 2002, is leading Hybrid

Base-type energy storage cabinets are typically used for industrial and large-scale applications, providing robust and high-capacity storage solutions. Integrated Energy Storage Container.

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · There are several interesting milestones to oversee when manufacturing a Battery Energy Storage Sys- tem: • Battery pack assembly and testing • PCS assembly and testing •

Energy management strategy of Battery Energy Storage Station

Sep 1, 2023 · Battery energy storage is widely used in power generation, transmission, distribution and utilization of power system [5]. In recent years, the use of large-scale energy

Overview of Battery Energy Storage (BESS) commercial

Sep 9, 2021 · Overview of Battery Energy Storage (BESS) commercial and utility product landscape, applications, and installation and safety best practices Jan Gromadzki Manager,

Development of Containerized Energy Storage System

Dec 24, 2014 · Our company has been developing a containerized energy storage system by installing a varyingly utilizable energy storage system in a container from 2010. The module

Battery Energy Storage Station (BESS)-Based Smoothing

Mar 7, 2013 · The battery energy storage station (BESS) is the current and typical means of smoothing wind- or solar-power generation fluctuations. Such BESS-based hybrid power

2.15MWh储能项目系统方案 2.15MWhEnergystora

Oct 25, 2023 · 1.1 系统概述System Overview 根据项目需求, 需要配备1 个20HQ 集装箱, 装箱容量为2.15MWhAccording to the project demand,one 20HQ container is needed to place the

Flexible energy storage power station with dual functions of power

Nov 1, 2022 · The high proportion of renewable energy access and randomness of load side has resulted in several operational challenges for conventional power systems. Firstly, this paper

Structural design of energy storage container power

The containerized configuration is a single container with a power conversion stationary energy storage such as in the stabilization of renewable energy, the adjustment of power grid

Container energy storage standard production line

ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries and all control,interface,and auxiliary

Container energy storage power station types

ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries and all control,interface,and auxiliary

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Utility-scale BESS system description — Figure 2. Main circuit of a BESS Battery storage systems are emerging as one of the potential solutions to increase power system

Energy storage container assembly line process standards

The battery energy storage system can also be used continuously to provide a number of benefits in a wide range of applications: Conclusion: The assembly line for energy storage battery

Battery energy storage system (BESS) integration into power generation

4 days ago · BESS can help enable increased electrification of oil and gas facilities by improving onsite power generation efficiency and reliability and supporting the integration of intermittent

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

6 FAQs about [Energy storage container assembly line base station power generation]

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

Can a battery storage system increase power system flexibility?

sive jurisdiction.—2. Utility-scale BESS system description— Figure 2.Main circuit of a BESSBattery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, suc

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

What is a 2MW energy storage system?

2MW energy storage system is currently in the process of being commissioned on the Orkney Islands, where wind power, wave power and tidal power plants are part of the energy supply mix and power is exported to or imported from the British mainland through 33kV submarine cables.

What are the functions of CATL lithium-ion battery energy storage system?

The functions of CATL's lithium-ion battery energy storage system include capacity increasing and expansion, backup power supply, etc. It can adopt more renewable energy in power transmission and distribution in order to ensure the safe, stable, efficient and low-cost operation of the power grid.

Learn More

- The working power generation of the communication base station battery energy storage system includes

- Liquid Cooling Container Energy Storage System ESS Power Base Station

- Battery energy storage system power generation in the communication base station room

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- Eritrea communication base station energy storage photovoltaic power generation maintenance

- Dominican communication base station energy storage photovoltaic power generation

- 25MW Base Station Container Energy Storage Power Station

- Helsinki Power Energy Storage ESS Base Station

- Energy storage container assembly automatic line

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.