Optimization of 5G communication base station cabinet based on heat

This paper explores the effects of phase change temperature (16—30 ℃), the installation location of phase change materials (PCMs), and phase change ventilation on the energy consumption

Revolutionizing Energy: Liquid Cooling Battery Cabinet

The Future of Energy Storage: The Role of Advanced Cooling As the demand for high-capacity energy storage continues to surge across commercial and industrial sectors, the technology

Cooling for Mobile Base Stations and Cell Towers

BackgroundUnattended base stations require an intelligent cooling system because of the strain they are exposed to. The sensitive telecom equipment is operating 24/7 with continuous load

Communication Base Station Battery Cabinets | HuiJue

Behind every communication base station battery cabinet lies a complex engineering marvel supporting our hyper-connected world. As 5G deployments surge 78% YoY (GSMA 2023),

Lithium Storage Base Station Cabinets | HuiJue Group E-Site

Why Are Telecom Operators Struggling with Energy Demands? As 5G networks expand globally, lithium storage base station cabinets have become critical infrastructure. But here''s the

Battery Cabinet Thermal Management | HuiJue Group E-Site

When battery cabinet thermal management fails, what follows? Catastrophic thermal runaway or gradual capacity decay? As global energy storage deployments surge 240% since 2020

Energy storage cabinet production and processing

Nov 30, 2022 · Breakthroughs have been made in a variety of energy storage technologies. Lithium-ion batterydevelopment trends continued toward greater capacities and longer

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

How Battery Cabinet Cooling Technology Works The core principle behind Battery Cabinet Cooling Technology is its superior heat transfer capability. In a typical setup, a dielectric

High Voltage Battery Cabinet for modern energy.

Jul 9, 2025 · The transition to renewable energy has placed a significant focus on efficient power storage, making the High Voltage Battery Cabinet a cornerstone of modern energy infrastructure.

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Research on Heat Dissipation of Cabinet of Electrochemical Energy

Apr 1, 2025 · According to the actual size of a company''s energy storage products, this paper also considered the liquid cooling cooling system, air cooling cooling system and lithium-ion battery

Study on performance effects for battery energy storage

Feb 1, 2025 · By increasing air supply volume, cooling effect of cooling system can be improved. Design A has lower temperature standard deviation than other three designs. Effect of

Energy Storage Cabinet Ventilation | HuiJue Group E-Site

As global deployments of battery cabinets surge – projected to reach 742 GWh capacity by 2027 – ventilation efficiency emerges as the make-or-break factor. Have we underestimated the

Energy Storage System Cooling

May 5, 2025 · Depending on the location of the base station, temperatures may range from a high of 50°C to a low of -30°C. The heat generated within the battery cabinet can vary depending

6 FAQs about [Battery cabinet base station energy heat shrink production]

How long does a battery last in a cellular base station?

The heat generated within the battery cabinet can vary depending on the ambient temperature. For reliable operation and maximum useful battery life, the enclosure must be maintained between +10°C to +30°C. Batteries used in cellular base stations are usually placed in cabinets to protect the equipment. No battery lasts forever.

How to improve battery pack performance?

As electricity flows from the charging station through the charging cables and into the vehicle battery cell, internal resistances to the higher currents are responsible for generating these high amounts of heat. Active water cooling is the best thermal management method to improve battery pack performance.

What is a cellular base station battery?

Batteries used in cellular base stations are typically located in cabinets that are vented to protect the vital equipment from the fumes and corrosive chemicals found in the wet cell batteries, which are often lead– acid or valve regulated lead-acid (VRLA).

What factors affect battery performance?

In battery back-up systems, heat and overcharging are two of the most important factors that lead to battery degradation, lower performance and even thermal runaway. Controlling and stabilizing the ambient temperature seen by the back-up battery is critical to battery performance and lifetime.

What happens if a battery is damaged by heat?

Once the battery is damaged by heat, the capacity cannot be restored. In battery back-up systems, heat and overcharging are two of the most important factors that lead to battery degradation, lower performance and even thermal runaway.

What is a battery back-up system?

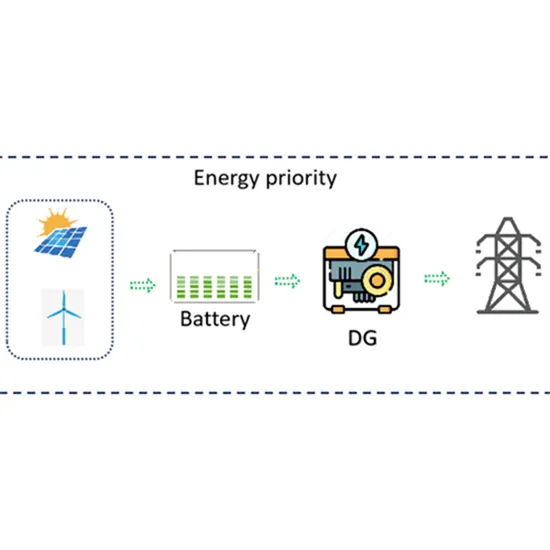

Battery back-up system used for the Telecom Industry. A battery back-up system consists of a series of power inverters, charge controllers/rectifier, and storage batteries. According to FCC order 07-177, when the power to a cellular antenna tower goes out, emergency batteries must provide back-up power for at least 8 hours.

Learn More

- Battery energy storage system 4-bay cabinet for communication base station

- 9V energy storage cabinet battery price base station

- How to choose the heat dissipation of the battery energy storage system of the communication base station

- Energy storage cabinet battery box base station and price

- Energy storage cabinet battery products base station power generation

- Energy storage cabinet battery protection ESS power base station

- Kigali New Energy Battery Cabinet Base Station Power Generation Store

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- Brasilia Base Station Energy Storage Battery Site Cabinet

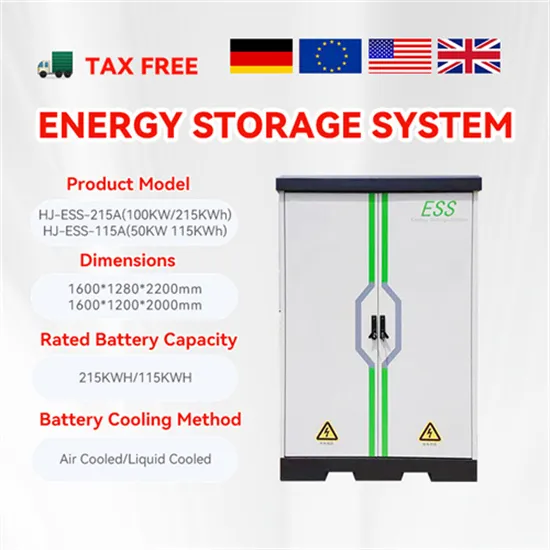

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.