3440 KWh-6880KWh Liquid-Cooled Energy Storage

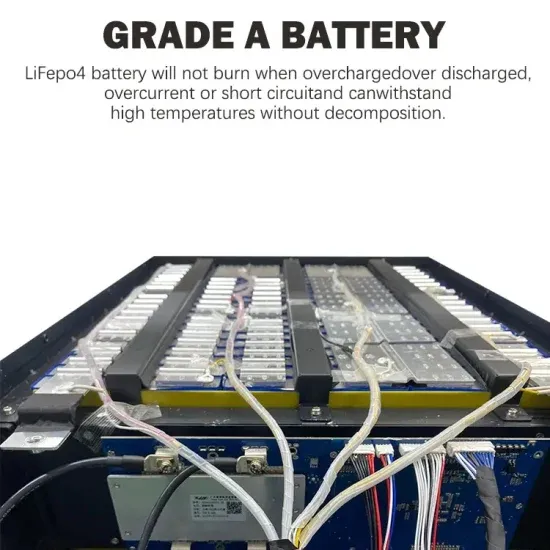

Huijue''s Liquid-Cooled Energy Storage Container System, powered by 280Ah LiFePO4, offers intelligent cooling, efficiency, safety, and smart O&M for diverse applications, including peak

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · In the ever-evolving landscape of battery energy storage systems, the quest for efficiency, reliability, and longevity has led to the development of more innovative

High-uniformity liquid-cooling network designing approach for energy

Nov 1, 2024 · This investigation presents an efficient liquid-cooling network design approach (LNDA) for thermal management in battery energy storage stations (BESSs). LNDA can output

What is Immersion Liquid Cooling Technology in Energy Storage

Dec 11, 2024 · Immersion liquid cooling technology is an efficient method for managing heat in energy storage systems, improving performance, reliability, and space efficiency.

Liquid Cooling Energy Storage System | GSL Energy

Discover GSL Energy''s advanced liquid cooling energy storage systems for commercial and industrial applications. Scalable to 5MWh, certified by UL, CE,CEI and IEC. Improve energy

Evolution of Thermal Energy Storage for Cooling

First Generation of Thermal Energy Storage Cooling of commercial ofice buildings became widespread after World War II, and its availability contributed to the rapid population growth in

液冷散热技术在电化学储能系统中的研究进展

Apr 1, 2024 · The findings indicate that liquid cooling systems offer significant advantages for large-capacity lithium-ion battery energy storage systems. Key

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · By improving the efficiency, reliability, and lifespan of energy storage systems, liquid cooling helps to maximize the benefits of renewable energy sources. This not only

Liquid Cooling Energy Storage Design Safety: Innovations,

Jan 22, 2024 · That''s where liquid cooling energy storage design safety becomes the superhero we didn''t know we needed. As the global energy storage market rockets toward $33 billion

Liquid Cooling Energy Storage System Design: The Future of

May 18, 2025 · Ever wondered how your smartphone battery doesn''t overheat during a 4K video binge? Now imagine scaling that cooling magic to power entire cities. That''s exactly what

Elevating utility-scale energy storage with HyperStrong''s liquid

Aug 22, 2024 · Among the many energy storage systems on the market, HyperStrong''s HyperBlock III distinguishes out thanks to its cutting-edge battery liquid cooling system. This

Why More and More Energy Storage Companies Are Choosing Liquid Cooling

Dec 13, 2024 · Explore the benefits of liquid cooling technology in energy storage systems. Learn how liquid cooling outperforms air cooling in terms of efficiency, stability, and noise reduction,

Revolutionizing Energy Storage: Liquid-Cooled Systems for

Mar 1, 2024 · The integration of liquid cooling technology into industrial and commercial energy storage systems represents a significant stride toward efficiency, reliability, and sustainability.

Trina Storage''s Elementa 2 liquid cooling system earns EPD

Mar 19, 2025 · Trina Storage has achieved a global milestone with its Elementa 2 liquid cooling system, becoming the world''s first energy storage product to earn a 20-year full lifecycle

232kWh Liquid Cooling Battery Energy Storage System | GSL Energy

Mar 26, 2025 · GSL Energy has taken another significant step in advancing energy storage solutions by installing a 232kWh liquid cooling battery energy storage system in Dongguan,

Energy storage cooling system

Dec 8, 2024 · Therefore, the liquid cooling system is more conducive to maintaining the performance and life cycle of the battery, and by increasing the operating hours and extending

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

6 FAQs about [Georgia liquid cooling energy storage]

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

Are liquid cooled battery energy storage systems better than air cooled?

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. “If you have a thermal runaway of a cell, you’ve got this massive heat sink for the energy be sucked away into. The liquid is an extra layer of protection,” Bradshaw says.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

How long is a 5MWh liquid-cooling energy storage cabin?

The layout project for the 5MWh liquid-cooling energy storage cabin is shown in Figure 1. The cabin length follows a non-standard 20’GP design (6684mm length × 2634mm width × 3008mm height). Inside, there are 12 battery clusters arranged back-to-back, each with an access door for equipment entry, installation, debugging, and maintenance.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Learn More

- Liquid Cooling Energy Storage Manufacturer in Cote d Ivoire

- Liquid Cooling Energy Storage Cabinet Commercial Use

- Huawei Czech Liquid Cooling Energy Storage

- Advantages of China-Africa Liquid Cooling Energy Storage

- Tallinn EK Liquid Cooling Energy Storage Project

- Liquid Cooling Energy Storage Benefits in Colon Panama

- Liquid Cooling Energy Storage Construction

- Democratic Republic of Congo liquid cooling energy storage cabinet site requirements

- Liquid cooling of Heishan energy storage power station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.