Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · To achieve superior energy efficiency and temperature uniformity in cooling system for energy storage batteries, this paper proposes a novel indirect liquid-cooling system based

Solar panels and liquid cooling energy storage

This is a Full Energy Storage System for C& I / Microgrids. JinkoSolar''''s EAGLE CS is a fully integrated, scalable, turnkey ac-coupled energy storage system for C& I and utility

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · By improving the efficiency, reliability, and lifespan of energy storage systems, liquid cooling helps to maximize the benefits of renewable energy sources. This not only

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Jul 7, 2025 · Against the backdrop of accelerating energy structure transformation, battery energy storage systems (ESS) are widely used in commercial and industrial applications, data

World''s First Immersion Cooling Battery Energy Storage

Mar 21, 2023 · The Meizhou Baohu energy storage power plant in Meizhou, South China''s Guangdong Province, was put into operation on March 6. It is the world''s first immersed liquid

Liquid nitrogen energy storage and liquid cooling

Liquid nitrogen storage comes with several safety risks:. A first risk is pressure build-up in the tank or container and the subsequent danger of explosion. If the cryogenic liquid heats up due to

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Liquid cooling system for battery modules with boron

Lithium-ion batteries (LIBs) have been extensively employed in electric vehicles (EVs) owing to their high energy density, low self-discharge, and long cycling life.1,2 To achieve a high energy

Top 10 liquid cooling energy storage

Top 10 liquid cooling energy storage Furthermore, the energy storage mechanism of these two technologies heavily relies on the area''''s topography [10] pared to alternative energy storage

【World-first】Kortrong Energy Storage joins hands with

Mar 15, 2023 · The immersion energy storage system newly developed by Kortrong has been successfully applied to the world''s first immersion liquid cooling energy storage power station,

The First 100MW Liquid Cooling Energy Storage Project in

The project (hereinafter "the Ningxia Project") is located in Ningdong Town, Lingwu City, Ningxia Province, which started construction in September 2022 and was connected to the grid on

Liquid-Cooling ESS: The Key to Efficient Energy Storage

Feb 28, 2025 · Discover the benefits of liquid-cooling ESS for efficient energy storage systems. Improve battery lifespan, enhance safety, and optimize performance with advanced liquid

Liquid Cooling Energy Storage System Design: The Future of

May 18, 2025 · Now imagine scaling that cooling magic to power entire cities. That''s exactly what liquid cooling energy storage system design achieves in modern power grids. As renewable

Liquid cooling energy storage for production batteries

The cooling liquid absorbs heat from the battery module, then passes through a condenser for cooling before returning to the liquid tank. J. Energy Storage, 64 (2023), Article 107167.

What material is the liquid cooling energy

Aug 19, 2024 · The construction of liquid cooling energy storage cabinets consists of several key components. 1. Steel frame, 2. Insulation materials, 3. Liquid

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

125KW/233KWh Liquid-Cooling Energy Storage

Dec 30, 2024 · In order to ensure the safety of energy storage power stations, the selection and design of energy storage system equipment should follow the principles of "prevention first,

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which Cooling

Jul 23, 2025 · Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Liquid Cooling Energy Storage Power Station Solution

The power station is equipped with 63 sets of liquid cooling battery containers (capacity: 3.44MWh/set), 31 sets of energy storage converters (capacity: 3.2MW/set), an energy storage

Liquid cooling energy storage with solar photovoltaic

Air cooling needs less energy as compared with water cooling, while, cooling capacity of water is more than the cooling capacity of air. Wang et al. [6] focused on the direct-contact fluid film

What material is the liquid cooling energy storage frame

May 12, 2024 · The liquid cooling energy storage frame is predominantly constructed using advanced materials such as 1. Aluminum, which provides a lightweight yet sturdy structure, 2.

Analysis of heat transfer characteristics of a novel liquid CO2 energy

Nov 1, 2024 · As the installed capacity of renewable energy such as wind and solar power continues to increase, energy storage technology is becoming increasingly crucial. It could

Liquid cooling design requirements for energy storage

A liquid air-based cooling system applied in data centers should not only meet the maximum cooling requirements of data center but also demonstrate good performance two types of

Energy Storage System Cooling

May 5, 2025 · Background Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when

Liquid Cooling Energy Storage Battery Bidding Project

Energy storage liquid cooling systems generally consist of a battery pack liquid cooling system and an external liquid cooling system. The core components include water pumps,

Liquid Cooling Solutions for Energy Storage Systems.

May 2, 2025 · The complete system Our innovative liquid cooling solutions offer numerous advantages, including efi cient heat dissipation for longer battery life, even temperature

Thermal Management Technology of 1MWh BESS Energy Storage

Dec 27, 2024 · The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

Liquid Cooling Energy Storage System Cost Analysis

The 2020 Cost and Performance Assessment provided installed costs for six energy storage technologies: lithium-ion (Li-ion) batteries, lead-acid batteries, vanadium redox flow batteries,

Liquid cooling energy storage solar power generation

To protect the environment and save fossil fuels, countries around the world are actively promoting the utilization of renewable energy [1].However, renewable energy power

6 FAQs about [Liquid Cooling Energy Storage Construction]

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

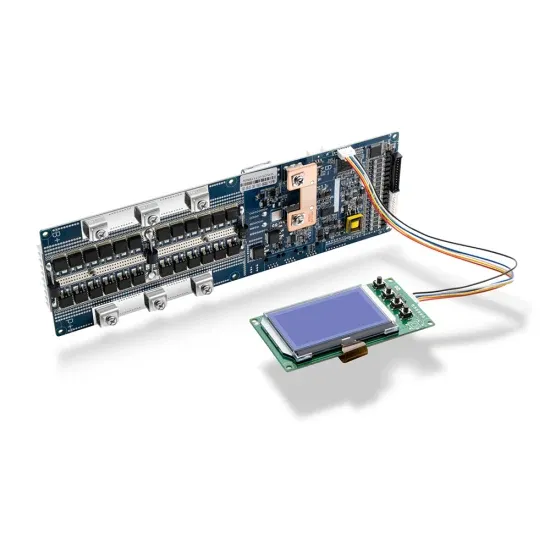

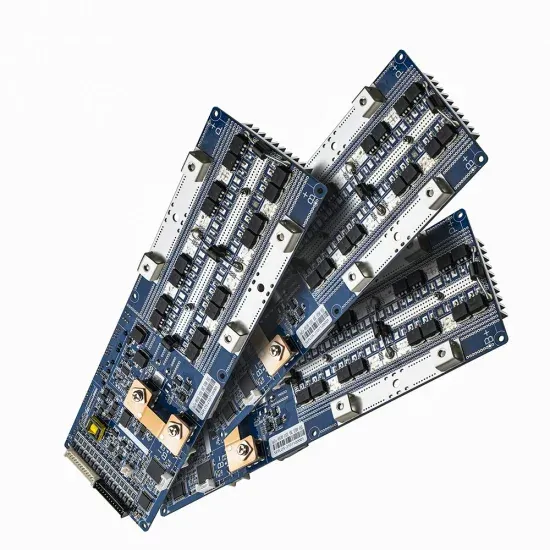

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

Learn More

- How many liquid cooling energy storage manufacturers are there in New Zealand

- Pros and cons of air cooling and liquid cooling of energy storage cabinets

- Wall-mounted energy storage liquid cooling unit

- Bloemfontein energy storage container liquid cooling system solution

- Guinea-Bissau Liquid Cooling Energy Storage Cabinet Production

- Industrial energy storage liquid cooling

- Tallinn EK Liquid Cooling Energy Storage Project

- Moldova Immersed Liquid Cooling Energy Storage

- Huawei Paris Liquid Cooling Energy Storage Cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.