How to measure the output voltage of the inverter

Generally speaking, for the output voltage of the inverter, we are concerned about the effective value of the fundamental wave. The 380V and 690V inverters we often say, as well as the

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · Power supply Rectifier (converter) PWM control Inverter The voltage output from the inverter is in pulse form. The pulses are smoothed by the motor coil, and a sine wave

Inverter Output Voltage Calculation calculation for Electrical

Jan 25, 2024 · Popularity: ⭐⭐⭐ Inverter Output Voltage Calculation This calculator provides the calculation of the output voltage of an inverter for electrical engineering applications.

How to measure the inverter output voltage-EEWORLD

Inverter output voltage measurement Generally speaking, for the inverter output voltage, we are concerned about the fundamental wave effective value. The 380V and 690V inverters we often

Power and Efficiency Measurement of Motors and Inverters

Mar 7, 2025 · In addition, torque and rotational speed can be input together with voltage/current electrical signals, enabling evaluation of inverter efficiency, motor efficiency and overall

Inverter Voltage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · The modulation index in inverters is a measure of the ratio of the output voltage to the maximum possible output voltage under given conditions. It''s crucial for optimizing inverter

Inverter Voltage Measurement Methods in context of inverter voltage

Aug 30, 2024 · Introduction: Inverters convert DC power to AC power, and their output voltage is a critical parameter that affects the overall performance of the system. Inverter voltage

DMM for inverter output voltage measurement | FAQ | Hioki

A The output voltage of a PWM inverter contains harmonics, in addition to the fundamental wave. On the other hand, when measuring a general inverter''s output voltage, only the fundamental

LMG600 Series Application: Traction inverter and its high

A complete efficiency measurement on the electric drive train is usually performed by measuring the electrical power between the respective main components: high-voltage battery (HV

High-precision Power Measurement of SiC Inverters

Jan 16, 2023 · Fig. 6 provides a voltage wiring schematic describing measurement of the output power of a 3-phase3-wire inverter. Since the power analyzer will measure line voltage, a large

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · Description This reference design realizes a reinforced isolated three-phase inverter subsystem using isolated IGBT gate drivers and isolated current/voltage sensors. The

How to calibrate the AC-Output voltage of an

Jun 14, 2024 · If you experience any misbehaviour of two inverters or more when they are connected in parallel, it is critical to measure the actual output voltage

How to measure output voltage from a VFD to a motor

Oct 7, 2019 · In a VFD, the pulse width modulation (PWM) inverter regulates both voltage and frequency to the motor. The voltage and frequency to the motor is varied by modulating the

Measurement Device for Inverter Output Impedance

Nov 12, 2020 · Inverter output impedance is an important parameter for assessing the stability of a grid-connected system. However, measuring the inverter output impedance is not

predator 9500 inverter voltage output measurement

Apr 21, 2024 · I bought a predator 9500 inverter generator a few years back. I am running into a problem with it, it does not run my 240 AC appliance. I tried measuring the voltage using a

Inverter Voltage Measurement Methods in context of inverter voltage

Aug 30, 2024 · Accurate measurement of the inverter voltage is crucial for ensuring proper operation, fault detection, and control. This article reviews various methods for measuring

Automeasurement of the Inverter Output Voltage Delay

Nov 27, 2013 · This paper proposes a novel method to automatically obtain the total output voltage delay curve, which is a significant part of the inverter voltage error model. Unlike

How to do output power measurement of a three phase inverter

Dec 24, 2024 · Here are the details: I am trying to measure output power of a three phase inverter using "Power Measurement (Three-Phase)" block. For my project it is very important to

Understanding Inverter Current: Types, Factors

Aug 11, 2025 · Inverter current is basically an important aspect of the process of electrical power conversion. Where the size of the input and output inverter

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · Inverter Voltage Formula: Inverter voltage (VI) is an essential concept in electrical engineering, particularly in the design and operation of power electronics systems. It describes

Online Measurement of Rise and Fall Times in SiC MOSFET-Based Inverter

Sep 6, 2024 · A novel detector circuit designed to precisely measure rise and fall time in the output voltage of SiC-based inverters is presented in this paper. Such measurements are

Output voltage measurement | FAQ | MITSUBISHI ELECTRIC FA

Can I measure the output voltage from the inverter? The inverter''s output voltage is controlled by switching DC voltage and has a pulse voltage waveform. (It is not a clean sine wave.)

AMC1311: Inverter Line-Line Output voltage measurement

Nov 6, 2024 · Part Number: AMC1311 Other Parts Discussed in Thread: AMC3330 Tool/software: Hi, I am working on a voltage sensing circuit that requires sensing an AC 60 Hz voltage. I also

6 FAQs about [Inverter output voltage measurement]

What is a pulse width modulated inverter?

Innovative measuring instruments are needed to be able to test and optimize the drive train of an electric vehicle. They must enable both highly accurate power measurements and calculation of various intermediate values. A pulse width modulated inverter converts a DC voltage into an AC voltage with variable frequency and amplitude.

How are currents and voltages measured in a pulse width modulated inverter?

The currents and voltages are measured in all three lines. Despite the pulsed voltage of the pulse width modulated inverter, the current is still approximately sinusoidal. Therefore, the current signal is used to derive the cycle time for mean-value calculation in the power measurement.

How to calculate inverter voltage?

The inverter voltages eνM with ν = 1, 2, 3, according to the corresponding control signal, can take on the value +Ud /2 with Sν = 1 or the voltage value -Ud /2with Sν = 0. (2.01) To calculate the line voltages in the machine, first the mesh equations are set up: (2.02)

How to calculate instantaneous power delivered by pulse width modulated inverter?

The instantaneous power delivered by the pulse width modulated inverter can be calculated with these star voltages and currents (i1, i2, i3). (3.01) Fig. 3.2: Diagram showing a power measurement with an artificial star point Fig. 3.3 shows the result of a measurement with an artificial star point.

How to calculate total effective power delivered by pulse width modulated inverter?

The total effective power delivered by the pulse width modulated inverter is determined by calculating the mean value of the instantaneous power. Equation 3.02 shows the procedure in Perception. (3.02) The apparent power S is the product of the current RMS value and the voltage RMS value.

What happens if a pulse width modulated inverter is less than Delta?

If the sine voltage is greater than the delta voltage, a positive voltage is generated. The pulse width modulated inverter switches to a negative voltage if the sinusoidal voltage is less than the delta voltage. The frequency of the triangular voltage is equivalent to the switching frequency at which the power semiconductors switch.

Learn More

- Prague photovoltaic inverter output voltage

- Can the inverter output voltage

- Is the inverter output voltage 233v normal

- What is the inverter output voltage

- Inverter string output voltage

- Tl494 inverter output voltage is low

- AC voltage measurement of string inverter

- Inverter protection voltage and output voltage

- Muscat inverter output voltage

Industrial & Commercial Energy Storage Market Growth

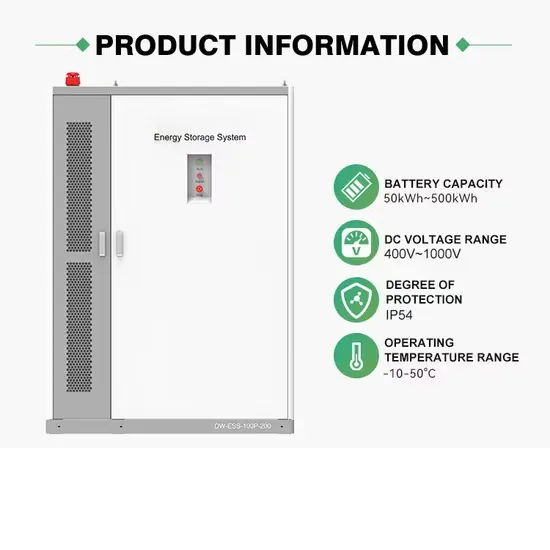

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.