A system for inverter protection and real-time monitoring

Oct 29, 2015 · A commonly used protection circuit is shown in Fig. 1 [4]. The inverter output current, load voltage and filter capacitor current are sensed and compared to preset limits. If

Core Protection Mechanisms of Inverters-Knowledge-Bidirection Inverter

Inverters are core devices in scenarios like photovoltaic power generation and electric vehicle charging, and their safe operation depends on various protection mechanisms. This article will

Inverter Safety Features and Protections in context of inverter voltage

Aug 31, 2024 · The SCP feature prevents damage to the inverter due to short-circuit conditions between the output terminals or between an output terminal and ground. It typically involves a

Understanding the Protection Functions of

Mar 31, 2023 · In addition to the function that regulates speed, the inverter also encompasses a safeguard function for the motor. The inverter is a controlling

Solar Hybrid Inverter: Protection Features & Maintenance Tips

Dec 17, 2024 · Discover essential protection features and maintenance tips for solar hybrid inverters. Ensure optimal performance, extend lifespan, and protect your investment with

15 important functions of solar inverter protection –

Dec 14, 2023 · This article will introduce you to some common functions of solar inverter protection, including input overvoltage/overcurrent, input reverse polarity, output

How Inverter Overload Protection Keeps Devices

Apr 21, 2025 · Overvoltage protection activates when the input or output voltage exceeds a defined threshold. It protects the inverter and your devices from

Reference Design for Reinforced Isolation Three-Phase

May 11, 2022 · A typical application of a three-phase inverter using six isolated gate drivers is shown in Figure 1. Note that each phase uses a high-side and a low-side IGBT switch to apply

Short-Circuit Protection for Power Inverters

May 18, 2025 · IR''s monolithic high voltage technology allows the IR2x14 and IR2x141 families to safely drive 110Vac to 380Vac applications and provide capability to withstand up to 600Vdc or

Do Lento Inverters Have Protection Against Power Surges and Voltage

However, in areas with extreme or frequent voltage instability, using an external stabiliser can provide additional protection and ensure smooth operation. Do inverters have overload

6 FAQs about [Inverter protection voltage and output voltage]

What happens if an inverter reaches a safe range?

Inverters equipped with over- and under-voltage protection automatically monitor the input and output voltage levels. If the voltage deviates from the preset safe range, the inverter will either shut down or adjust its output to bring the voltage back within acceptable limits.

What is inverter protection circuit?

Fig. 1. An inverter protection circuit. In motor drive applications, the inverters are usually protected only from overloading conditions, using either intrusive current sensing techniques, which measure the DC input current or the load current , , or special motor control algorithm techniques , , .

What is the function of inverter?

Their function is to convert a DC input voltage to an AC output voltage of desired amplitude and frequency. The inverter specifications are the input and output voltage range, the output voltage frequency and the maximum output power. 1.

What is a voltage source inverter (VSI)?

Voltage source inverters (VSI) include an L-C filter at the output stage thus, in case of an output short-circuit condition, the filter inductance limits the output current rising rate . In both preceding cases, the high inductance value leads to inverter size and power losses increase. A commonly used protection circuit is shown in Fig. 1 .

How do you protect a power inverter?

Protection against these involves the use of circuit breakers and fuses that automatically disconnect the circuit when excessive current is detected. These protective devices must be installed on both the AC and DC sides of the inverter. They operate by breaking the circuit, thus stopping the flow of electricity and preventing damage.

Why do inverters need protection?

Ensuring their protection against electrical and environmental factors is essential for optimal performance and longevity. This article outlines the key protections needed to safeguard inverters from common risks such as surges, overcurrent, and temperature extremes.

Learn More

- Sungrow inverter unit voltage protection

- The maximum voltage output by the inverter

- 12v inverter protection voltage change

- Is the inverter output voltage 233v normal

- What is the inverter output voltage

- Muscat inverter output voltage

- Tl494 inverter output voltage is low

- Inverter high voltage output price

- How many volts does the inverter output voltage change

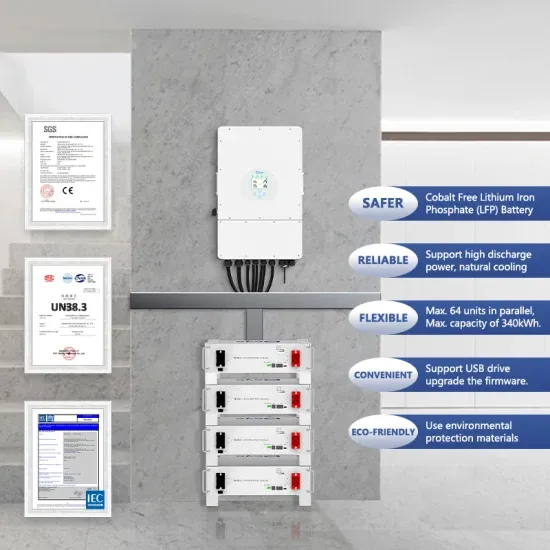

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.