100-A Current Source Reference Design Using Two

Jul 18, 2015 · When multiple modules are operated in parallel, an eight-layer layout with 2-oz. copper is recommended to improve thermal conduction. Increased copper thickness is

Paralleling DC/DC power modules: what you need to know

Aug 6, 2011 · When multiple PTH08T250W modules are paralleled, the amount of capacitance must be enough to filter the input and output and meet the transient require-ments of the high

Parallel Connection of Power Electronic Devices

May 12, 2020 · Power modules in fact usually reach their power handling capability by paralleling multiple dice. Of course it is easier for a module manufacturer to parallel devices since the dice

Parallel Operation: Influence of Power Module Parameters

May 6, 2024 · The reference test setup was chosen for investigation of mod-ule parallel connection in the following chapters. CM450DA-66X module in the LV100 package is a

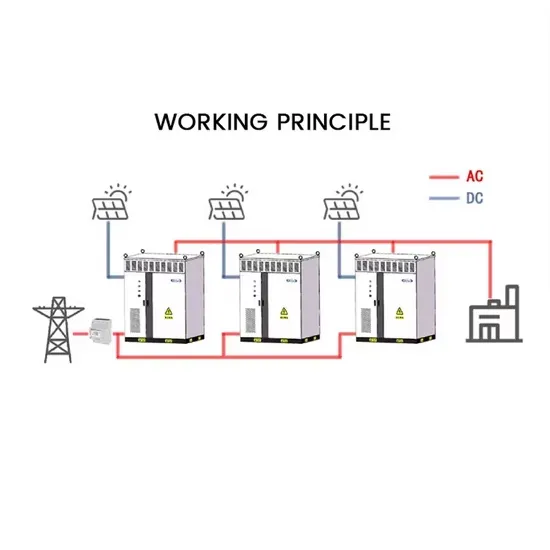

Telecom Base Station PV Power Generation System

Feb 1, 2024 · Telecom Base Station PV Power Generation System Solution Single Photovoltaic Power Supply System (no AC power supply) The communication base station installs solar

Parallel Configuration Guide for PCS and BMS Systems

May 9, 2024 · Scope: This document covers the parallel configuration of two PCs and BMS units to meet specific requirements. Systems Overview: Requirements: • Before initiating parallel

A practical example of hard paralleling SiC MOSFET

May 24, 2025 · Abstract Is it possible to design a matched gate driver and power PCB to hard parallel four 6 mΩ 1200 V SiC MOSFET modules? This was the question that this paper sets

Parallel Operation: Influence of Power Module Parameters

May 6, 2024 · The interface of power modules, such as power connection on DC and AC side, the design of gate driver, and the gate driver connection to the power modules, have an influence

MITSUBISHI SEMICONDUCTORS POWER MODULES

Oct 22, 2024 · The main electrodes are connected directly to the power chips using large di- ameter aluminum bonding wires. In order to help simplify power circuit and snubber designs or

How to Properly Operate Power Supply Modules | DigiKey

Aug 30, 2011 · Placing two modules in parallel creates a four-phase operation by shifting the slave module phases by 90 degrees. All slave modules operate in phase and 90 degrees out of

Parallel-connected battery module modeling based on

Jan 15, 2022 · Abstract Cell inconsistencies inevitably occur inside a battery module. Particularly, the inconsistencies in current distribution and heat generation in a parallel-connected battery

Paralleling power modules for high-current applications

Aug 6, 2011 · Input and output capacitors When multiple PTH08T250W modules are paralleled, the amount of capacitance must be enough to filter the input and output and meet the transient

5G Base Station BMS (Used in parallel)

沛城智能控制技术有限公司share Douban Baidu Post Bar Specification ModelP16S50A-0001-10A 1High stability 2High-precision detection 3Temperature protection 4Overvoltage protection

Parallel Connection of Power Electronic Devices

May 12, 2020 · A power module usually provides better performance than multiple discrete devices in terms of stray inductances, circuit complexity, and total thermal resistance. So how

100-A Current Source Reference Design Using Two

Jul 18, 2015 · However, the PTH08T250W incorporates a stackable controller feature that allows the outputs of multiple modules to be connected in parallel, thereby producing a reliable

IGBT Modules in Parallel Operation with Central and

Aug 14, 2025 · Introduction Parallel circuits are always necessary when the performance criteria of a single component are insufficient. This starts at the microscopic chip level with several

Murata-Base-station-app-guide

Sep 30, 2022 · Moving up the mast In the era of 4G, network installations typically relied upon heavy duty infrastructure such as large power masts and passive cables and antennas, with

iSitePower-M-5/10/15/20/25/30

Aug 22, 2023 · Test conditions:100% depth of discharge(DoD), 0.2Cratecharge & dischargeat 25°C, at the beginningof life. If no PV modules are installed or the system has not detected

Hard Paralleling SiC MOSFET Based Power Modules

May 24, 2025 · Paralleling must start with consideration of the module internal power and gate layout. The internal chip layout and module pin out can be designed to provide equal and

Series vs Parallel Solar Panels: Key Differences —

Apr 28, 2025 · When installing solar panels, one key decision is how to connect them for optimal performance. The two most common wiring configurations

6 FAQs about [Base station power module parallel connection]

Should I use two power modules in parallel?

Firstly, you may need more current than a single power module provides. Using two modules in parallel, the current to the load can be effectively doubled. Paralleling can also reduce the number of different power module types used, by meeting higher power requirements with lower power modules in parallel.

Why do I need a parallel power system?

A final reason is to reduce the number of different modules kept in stock by paralleling the same modules for different current and power needs across many program designs. This may also provide a lower cost advantage by earning higher quantity pricing discounts. However, not all modules can be paralleled.

Do module parameters influence current sharing and switching energy imbalance?

This understanding is important for proper module parallel operation inside the thermal and safe operation limits. This article describes the methodology of how to analyze the influence of module parameters on current sharing and switching energy imbalance for parallel operation of power modules.

Do paralleled modules have a minimum characteristic?

For this, it will be as-sumed that one of the paralleled modules has a minimum characteristic (resulting in maximum switching energy or current) while all other modules have the maximum characteristics (leading to minimum switch-ing energy or current).

How many central gate drivers are used to control parallel modules?

Only one central gate driver is used in combination with a low-inductive interface board to control the paralleled modules. The reference test setup was chosen for investigation of mod-ule parallel connection in the following chapters.

What affects static and dynamic current imbalance of power modules?

The interface of power modules, such as power connection on DC and AC side, the design of gate driver, and the gate driver connection to the power modules, have an influence on static and dynamic current imbalance of modules connected in parallel.

Learn More

- Base station wind power module configuration

- Base station power engineering process connection

- The function of base station power adapter module

- How much does Huawei base station power module cost

- Base station power module power supply description

- Power module under the base station

- Communication base station battery parallel connection method

- Communication base station 12v power module

- The power module of the communication base station is made adjustable

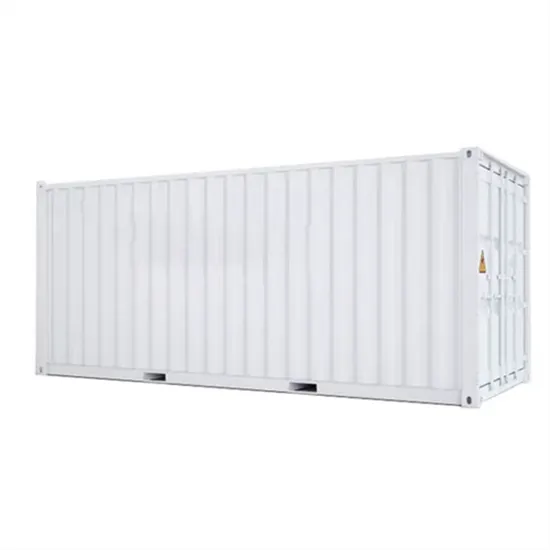

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.