Battery configuration dependence to power line communication

Feb 15, 2024 · Comparing PLC performance in various battery configurations and QAM orders. Power line communication (PLC) within future smart batteries facilitates the communication of

Battery configuration dependence to power line communication

Feb 15, 2024 · Abstract Power line communication (PLC) within future smart batteries facilitates the communication of high fidelity sensor data between smart cells and external systems, with

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Lithium Series, Parallel and Series and Parallel Connections Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by

Aggregation and scheduling of massive 5G base station backup batteries

Feb 15, 2025 · This paper proposes a price-guided orientable inner approximation (OIA) method to solve the frequency-constrained unit commitment (FC-UC) with massive 5G base station

Telecommunication base station system working principle

Jan 13, 2024 · Under normal circumstances, the power supply system operates in a parallel float charging state, where the rectifier module, solar module, load, and battery work in parallel; In

Telecom Base Station Backup Power Solution:

Jun 5, 2025 · Below are key design aspects to focus on: 1. Battery Pack Structure Design. Cell Selection: A 48V 100Ah battery pack is typically composed of 15

WHAT IS A PARALLEL BATTERY CONNECTION

Energy storage power station battery series and parallel connection In this in-depth guide, we will delve into the concepts of batteries in series and parallel at the same time, how to connect

How to Effectively Connect Batteries in Series and Parallel

Jan 4, 2025 · Yes, batteries can be configured in both series and parallel arrangements simultaneously, known as series-parallel configurations. This method allows users to achieve

Connecting batteries in parallel ŌĆō BatteryGuy Knowledge Base

May 3, 2024 · With secondary (rechargeable) batteries ŌĆō only use batteries of the same brand and age and make sure all the units are fully charged before connecting them together in parallel.

Battery configuration for communication base station

The base station battery system may be permitted to communicate with the grid in order to fully utilize the 5G base station battery resources. It can lessen the grid load''''s peak-to-valley

Method of communication between a battery powered terminal and a base

A method of communication between a user terminal powered by a battery and a base station allowing optimization of the management of the battery of the user terminal, includes a step of

Collaborative optimization of distribution network and 5G base stations

Sep 1, 2024 · In this paper, a distributed collaborative optimization approach is proposed for power distribution and communication networks with 5G base stations. Firstly, the model of 5G

Selection and maintenance of batteries for communication base stations

Abstract: The battery is the main means of power storage in the power supply system of the communication base station. This article focuses on the engineering application of the battery

Parallel-connected battery module modeling based on

Jan 15, 2022 · In practice, because of the lack of enough sensors to detect the current distribution and battery heat generation distribution, only the total current and terminal voltage of the

The communication base station battery pack is connected in parallel

Abstract: This article presents a new state-of-charge (SOC) balancing method with parallel and series output connected battery power modules (BPMs) in an active battery management

Collaborative Optimization of Base Station Backup Battery

Dec 18, 2023 · Collaborative Optimization of Base Station Backup Battery Considering Communication Load Published in: 2023 IEEE 7th Conference on Energy Internet and Energy

What is the purpose of batteries at telecom base

Feb 10, 2025 · The lead storage battery is the most widely used energy storage battery in the current communication power supply. Among the many types of

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

Modeling and aggregated control of large-scale 5G base stations

Mar 1, 2024 · In parallel, the deployment of 5th-generation mobile network (5G) infrastructures has rapidly expanded in recent years. The limited penetration capability of millimeter waves

6 FAQs about [Communication base station battery parallel connection method]

What makes a telecom battery pack compatible with a base station?

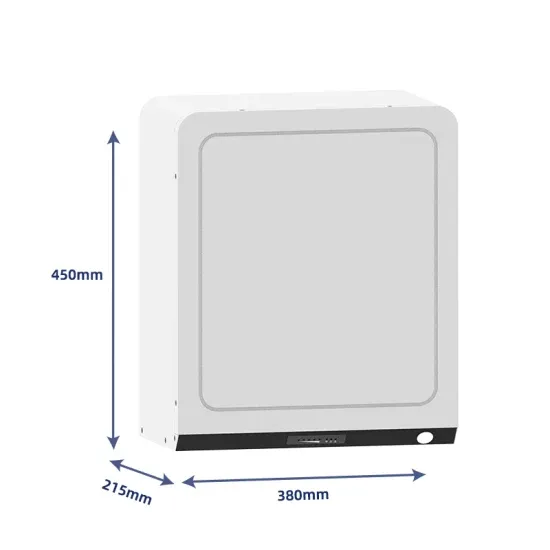

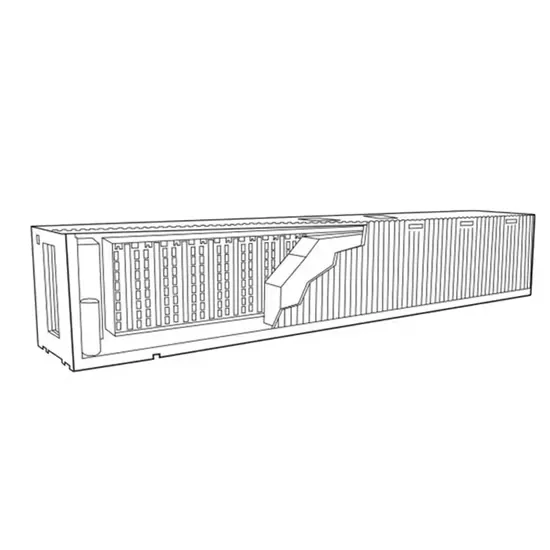

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery packŌĆÖs output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

Why are batteries connected in parallel?

Cells are often connected in parallel to achieve the required energy capacity of large-scale battery systems. However, the current on each branch could exhibit oscillation, thus causing concerns about current runaway or even system divergence.

Is a parallel battery system convergent?

We show the parallel battery system to be essentially a convergent, stable, and robust system with a highly precise and absolutely reliable battery management system. The long-term trajectory of batteries connected in parallel in repeated cycles will be enveloped in a closed orbit insensitive to initial states of systems.

Are parallel battery systems stable?

Nevertheless, we also warn about some risks behind stability. First, parallel battery systems inflict intrinsic capacity loss due to cell inconsistencies, causing capacity loss even reaching up to 34% according to the terminals of the closed orbit.

Can a parallel battery system work without E-SoC inconsistency?

Parallel systems without the E -SOC inconsistency can work well even with the negative trajectory slope. In summary, the parallel battery configuration generates inherent self-excited oscillation without requiring any external oscillating excitation, which raises concerns about stability within parallel battery systems.

Can a large-scale battery system be built parallel?

In an era of rapidly developing renewable energy and large-scale battery systems, the completion of this proof is reassuring and has enormous significance: the parallel configuration, inevitable for a large-scale BESS, is intrinsically safe, which lays the groundwork for building a large-scale BESS.

Learn More

- Connection method of two battery packs ab of base station

- Wind power method of battery energy storage system for Naypyidaw communication base station

- Georgetown Communication Base Station Battery 100KWh

- Ghana communication base station inverter grid connection maintenance construction

- How to deal with the grid connection of the inverter with communication base station on the roof

- What is the battery capacity of base station communication equipment

- Gabon communication base station lithium ion battery company ranking

- Working Principle of Wireless Communication Base Station Battery Energy Storage System

- Communication base station flow battery power supply solution

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.