Health monitoring by optical fiber sensing technology for

Feb 1, 2024 · This review summarizes current progress in optical sensing techniques for batteries with respect to various sensing parameters, discussing the current limitations of optical fiber

The Benefits of Maintenance-Free Lead Acid Batteries for Telecom Base

Telecom base stations are the backbone of modern communication infrastructure, requiring reliable and efficient power sources to operate continuously. In this context, maintenance-free

Lithium Iron Batteries for Telecommunications Base Stations

REVOV''s lithium iron phosphate (LiFePO4) batteries are ideal telecom base station batteries. These batteries offer reliable, cost-effective backup power for communication networks. They

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and Communications Technology)

Battery technology for communication base stations

The "Battery for Communication Base Stations Market" research report for 2024 offers a thorough and in-depth examination of the industry segmentation based on Types [Lead-acid Battery,

【MANLY Battery】Lithium batteries for communication base stations

Mar 6, 2021 · In the future, especially after the 5G upgrade, lithium battery companies will no longer simply focus on communication base stations, but on how the communication network

Communication Base Station Lead-Acid Battery: Powering

In an era where lithium-ion dominates headlines, communication base station lead-acid batteries still power 68% of global telecom towers. But how long can this 150-year-old technology

Optically Powered and Controlled Drones Using Optical Fibers

Mobile communication services are crucial during emergency disasters and temporary events, and future mobile communication systems should be able to provide such services. Airborne

How Energy Storage Lead Acid Batteries Are Revolutionizing Telecom Base

Dec 18, 2024 · In recent years, the telecommunications industry has witnessed a significant transformation, with energy storage lead acid batteries emerging as a game-changer for

Lead-Acid Battery Lifetime Estimation using Limited Labeled

Apr 8, 2022 · Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as well as to optimize operational

Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

5G base station application of lithium iron phosphate battery

Jan 19, 2021 5G base station application of lithium iron phosphate battery advantages rolling lead-acid batteries With the pilot and commercial use of 5G systems, the large power consumption

Communication Base Station Lead-Acid Battery: Powering

Why Are Lead-Acid Batteries Still Dominating Telecom Infrastructure? In an era where lithium-ion dominates headlines, communication base station lead-acid batteries still power 68% of global

Pure lead-acid batteries for telecommunication application

Mar 21, 2022 · In an international comparison, bridging times with battery storage vary from a few minutes to several hours and also place a high energy throughput load on the storage systems

A review on various optical fibre sensing methods for batteries

Oct 1, 2021 · Presents a critical review of all the main optical fibre sensing methods for batteries for the first time. Discusses the working principles of various optical fibre sensing methods

Energy Storage Solutions for Communication

Sep 23, 2024 · However, other options such as lead-acid batteries, flow batteries, and supercapacitors are also in use, each offering unique benefits suited for

Lead-Acid Battery Lifetime Estimation using Limited

Jan 21, 2024 · lular networks and avoid loss of revenue due to power outages, most of cellular base stations are equipped with battery backup power systems. These backup power systems

Lead-Acid Battery Lifetime Estimation using Limited Labeled

Apr 8, 2022 · To extend the number of labels, we propose an active semi-supervised SVM method with minimum human efforts. Finally, the obtained labeled dataset is fed into random

HISILICON Optical Modules in the field of communication base stations

Jan 12, 2025 · In addition, the optical module in the base station can also be used to achieve fiber backhaul connection, the base station signal back to the data center or the operator''s core

Lead-Acid vs. Lithium-Ion Batteries for Telecom

Mar 7, 2025 · While lead-acid batteries remain a cost-effective option, lithium-ion batteries are gaining popularity due to their longer lifespan, reduced

What is the purpose of batteries at telecom base

Feb 10, 2025 · Among the many types of batteries, why can lead-acid batteries become the first choice for telecom base stations? This is mainly due to its

Life cycle assessment of secondary use and physical

Apr 15, 2024 · Improving the environmental efficiency of the battery manufacturing process through LCA analysis can show the high environmental feasibility of using waste EV LIBs as

Optically Powered and Controlled Drones Using Optical

Dec 10, 2023 · Thus far, we have simultaneously transmitted RF data signals for airborne base stations in mobile communications and control signals for maneuvering drones over optical

A review on various optical fibre sensing methods for batteries

Oct 1, 2021 · This paper mainly discusses the current optical fibre sensing methods for batteries in terms of the working principles and critical reviews the sensing performance corresponding to

Carbon emission assessment of lithium iron phosphate batteries

Nov 1, 2024 · This study conducts a comparative assessment of the environmental impact of new and cascaded LFP batteries applied in communication base stations using a life cycle

Environmental feasibility of secondary use of electric vehicle

Jan 22, 2020 · Yang et al. [93] conducted an LCA study to compare the environmental impacts of retired LIBs and lead-acid batteries used in communication base stations and found that

Battery for Communication Base Stations Market

The Battery for Communication Base Stations market can be segmented by battery type, including lithium-ion, lead acid, nickel cadmium, and others. Among these, lithium-ion batteries

Optically Powered and Controlled Drones Using Optical

Nov 21, 2022 · Mobile communication services are crucial during emergency disasters and temporary events, and future mobile communication systems should be able to provide such

Life testing of plastic optical fibers for lead-acid battery fast

Jan 31, 2008 · Three of the optical fibers are used to measure density, and the fourth one as a reference to account for common-mode variation. The charge level of the battery can be

6 FAQs about [Lead-acid batteries and optical fibers for communication base stations]

Can optical fibre sensing improve battery chemistry?

Currently, the field of optical fibre sensing for batteries is moving beyond lab-based measurement and is increasingly becoming implemented in the in situ monitoring to help improve battery chemistry and assist the optimisation of battery management [4, 6].

Can optical fibre sensors be used in a battery system?

Besides, the cost of optical fibre sensors limits their implementation in practical battery systems, especially cell-level system. Therefore, this requires further development of the optical sensing methods in a cost-effective way compatible with industrial manufacturing processes as well.

Why do we need a battery sensing system?

Batteries have rapidly evolved and are widely applied in both stationary and transport applications. The safe and reliable operation is of vital importance to all types of batteries, herein an effective battery sensing system with high performance and easy implementation is critically needed.

What methods are used in battery sensing?

The methods discussed above have been conjunctively applied to the battery sensing, in the aspects of measuring temperature, strain (stress), RI, electrolyte density, flow change, oxygen concentration, SoC and SoH, the sensing parameters corresponding to each method are presented in Fig. 10. Fig. 10.

Can FBG sensors monitor temperature and bi-directional strain in a prismatic Li-ion battery?

3.3.1. Reference FBG method Nascimento et al. employed FBG sensors to simultaneously monitor the temperature and bi-directional strain in a prismatic Li-ion battery in 2018, as shown in Fig. 20. The measurement was conducted by attaching two different types of FBG sensors to the Li-ion battery surface on both x- and y-directions.

Is a one-entry configuration suitable for battery cells & packs?

Although a reflection-based configuration is preferred for battery cells due to the simplified sealing process and minimised risk of electrolyte leakage , the one-entry configuration is not suitable for the battery modules and packs.

Learn More

- Manufacturing lead-acid batteries for communication base stations

- Huawei makes lead-acid batteries for communication base stations

- Application for lead-acid batteries for communication base stations

- How to install lead-acid batteries in communication base stations

- Do lead-acid batteries for communication base stations need to be publicized

- Replacement of batteries for communication base stations

- How can lithium-ion batteries in communication base stations achieve Internet access

- How to avoid liquid flow batteries in communication base stations

- Photovoltaic power generation capacity of lead-acid batteries in Ouagadougou communication base station

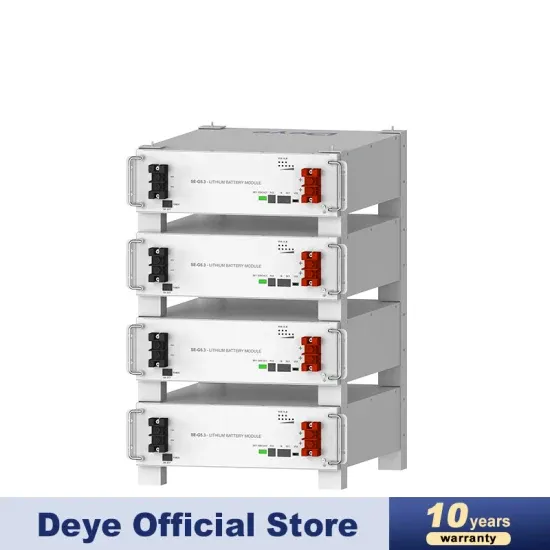

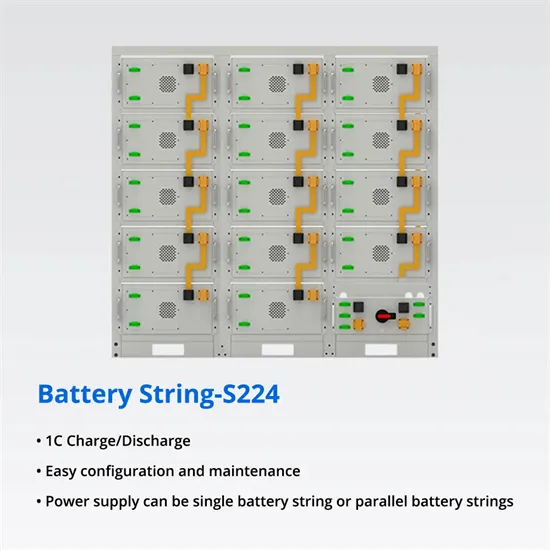

Industrial & Commercial Energy Storage Market Growth

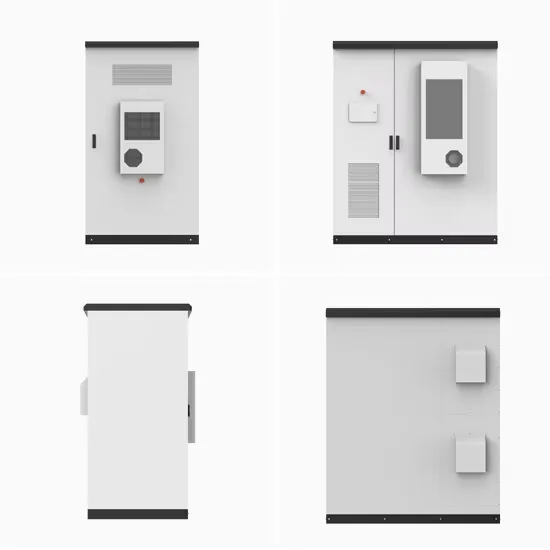

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.