Amazon : LiTime 3500W Pure Sine Wave Solar Inverter

Aug 1, 2024 · LiTime 3500W Pure Sine Wave Solar Inverter Charger, 48V DC to 120V AC All-in-One Solar Inverter, Built in 80A MPPT Charge Controller, for 48V Lead Acid/LiFePO4 Battery,

Do LiFeP04 batteries need a specific kind of inverter?

Apr 9, 2020 · I''m a total newbie at this, but I''m trying to decide on a 1000W pure sine wave inverter to pair with my LiFeP04 battery for my basic solar system for a van. I found a 1000W

Charging Battery While Connected To Inverter

Mar 3, 2023 · Can I charge a battery while it''s connected to an inverter? in short, the answer is Yes, you can charge a battery while using an inverter. but make

Home LifePO4 Battery With Inverter Single Phase Hybrid 220V

High quality Home LifePO4 Battery With Inverter Single Phase Hybrid 220V System from China, China''s leading Home LifePO4 Battery With Inverter product, with strict quality control LifePO4

All In One Inverter And Lithium Lifepo4 Battery

Jun 3, 2025 · HES PLUS All In One Inverter And Lithium Lifepo4 Battery 5KW-45KW Input Voltage: 48VDC | Output Voltage: 220/230/240VAC±2% | Battery: LiFePO4 Lithium 51.2VDC

Understanding the Compatibility of LiFePO4

6 days ago · LiFePO4 batteries have gained popularity in various applications due to their high energy density, long lifespan, and low maintenance requirements.

6kw to 50kw Three Phase String Inverter (LV) for 127

Aug 1, 2025 · This series inverter is specially designed for 127/220Vac,133/230Vac three-phase system, providing rated power at 33KW, 40KW, 45KW, 50KW. Equipped with large LCD and

220V Inverter And Battery All In One Solar Power System LiFePO4

LiFepo4 Grade A cells offer a higher number of charge-discharge cycles and better stability, making them a reliable choice for devices requiring high-performance, durable power

All in One Lithium Ion 220V Solar Inverter LiFePO4 Battery

Find verified All in One Lithium Ion 220V Solar Inverter LiFePO4 Battery Power Bank suppliers and manufacturers offering competitive wholesale prices. Browse detailed specs, bulk order

Best Inverter for LiFePO4 Batteries: Top Picks & Buying Guide

Apr 18, 2025 · LiFePO4 batteries are popular due to their long lifespan, low maintenance requirements and deep discharge capability. However, choosing the right inverter is critical to

All in One Lithium Ion 220V Solar Inverter LiFePO4 Battery

Aug 17, 2025 · 220V Hybrid Solar Off Grid 5.5KW 6KW11KW Inverter with Lithium Ion Battery 51.2V 100AH 200AH 300AH 400AH 5kwh 10KWh 15KWH 20KWh All In One Storage System

6 FAQs about [LiFePO4 battery 220v inverter]

Does a LiFePO4 inverter work with a battery?

The compatibility of the inverter’s communication protocol with the battery’s BMS is crucial. Without proper communication, the inverter may not be able to access the battery’s data, which can affect system performance and safety. The type of LiFePO4 battery and the design of the inverter can also impact compatibility.

Are LiFePO4 batteries compatible?

The type of LiFePO4 battery and the design of the inverter can also impact compatibility. Different battery manufacturers may have specific design requirements for their batteries. For example, some LiFePO4 batteries may require a specific charging profile or may be sensitive to overcharging or over-discharging.

Do LiFePO4 batteries need a BMS?

LiFePO4 batteries require a battery management system (BMS) to monitor and regulate their operation. The BMS ensures that the battery operates within safe parameters, including voltage, temperature, and current. When connecting LiFePO4 batteries to an inverter, it’s crucial to consider the compatibility of the BMS with the inverter.

How to charge LiFePO4 batteries in series?

LiFePO4 batteries should be charged with a multi-bank charger (not a Lead Acid charger, as recommended). This means each battery is charged at the same time but completely independent of the other.

How do I protect my LiFePO4 battery?

To keep your LiFePO4 battery in top condition and protect your inverter, follow these settings: Upper Voltage Limit: Set the upper charging limit to 55.5V. If necessary, you can push this up to 56.0V, but going beyond this increases the risk of damaging your cells. This setting is called BULK in many inverters, or absorption in others like Deye.

What are the best settings for a 16-cell LiFePO4 battery?

This article will guide you through the optimal settings for a 16-cell LiFePO4 battery to ensure long-lasting performance and avoid damage. When charging a LiFePO4 battery, the bulk of the energy is stored within a specific voltage range—typically between 3.0 to 3.45 volts per cell.

Learn More

- Power frequency inverter connected to 220v to charge the battery

- Power battery conversion 220v inverter

- 48v lead acid battery to 220v inverter

- Can a 12v inverter be powered by a 14v lithium battery

- Rooftop communication base station inverter grid-connected battery

- Can a 12V20A lithium battery be equipped with an inverter

- Base station lithium battery energy storage 100kw inverter price

- Communication inverter 48V to 220V

- 12V inverter 220V 5KW cost

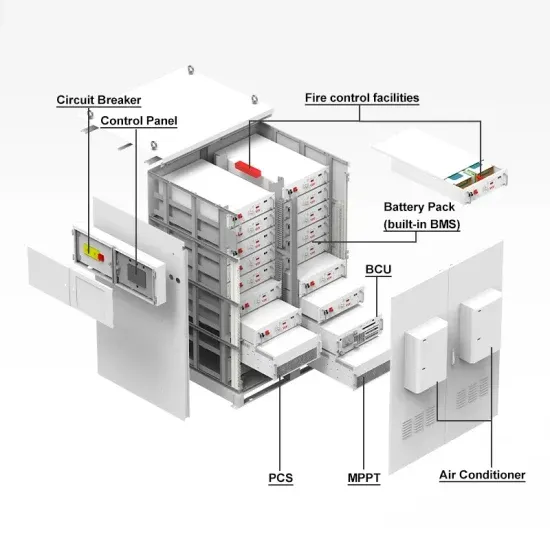

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.