Solar Photovoltaic Technology Basics | NREL

Mar 25, 2025 · Solar Photovoltaic Technology Basics Solar cells, also called photovoltaic cells, convert sunlight directly into electricity. Photovoltaics (often shortened as PV) gets its name

How Solar Inverters Work for Solar Panels

Feb 28, 2014 · In this article we discuss how inverters work, includ-ing string, or single-phase, and central, 3-phase inverters; explore major inverter functions, key components, designs,

What is a solar combiner box and why is it used

Mar 25, 2025 · Learn all about solar combiner boxes. Combiner boxes combine solar strings into a single power source for inverters, limiting energy loss and

Design and Sizing of Solar Photovoltaic Systems

Feb 2, 2022 · DESIGN AND SIZING OF SOLAR PHOTOVOTAIC SYSTEMS Photovoltaic (PV) systems (or PV systems) convert sunlight into electricity using semiconductor materials. A

Solar Integration: Inverters and Grid Services Basics

4 days ago · If you have a household solar system, your inverter probably performs several functions. In addition to converting your solar energy into AC

What is a photovoltaic inverter?Selection, Principles & Future

Apr 28, 2025 · Gain a deep understanding of the working principles, key classifications, and crucial roles of photovoltaic inverters in solar power generation systems. This article

Photovoltaic Basics (Part 2): Integrating the

Sep 30, 2024 · To effectively harness solar energy, it''s essential to understand how to properly configure the components of a system. This article focuses on

Solar Power Basics (A Comprehensive Beginner''s

Jun 15, 2022 · Welcome to a beginner''s guide on solar power basics, where we will walk through a solar electric power system and how to build one – Solar

10 Essential Features of an Inverter Box for Solar Panels

May 11, 2025 · These inverter boxes for solar panels are crucial for transforming sunlight into usable electricity, enabling you to effectively harness the sun''s power. With over 30 years of

Photovoltaic inverter classification and differences

The PV inverter topologies are classified based on their connection or arrangement of PV modulesas PV system architectures shown in Fig. 3. In the literature,different types of grid

The Basics Of Solar PV Systems | Solar Panels

Apr 23, 2023 · Get a good understanding of solar panels and inverters with this guide on the basics of solar PV systems. Learn how they work, their benefits,

Photovoltaics: Basic Principles and Components

Oct 14, 2013 · Photovoltaics: Basic Design Principles and Components If you are thinking of generating your own electricity, you should consider a photovoltaic (PV) system—a way to gen

The Basics of a PV Combiner Box: A Simple Guide for Solar

How a PV Combiner Box Works The main job of a PV combiner box is to merge the power from multiple solar panels into one stream, keeping the system organized and safe.

Understanding the Function of a Combiner Box in Solar Photovoltaic

May 10, 2024 · In the realm of solar photovoltaic (PV) systems, the efficient and safe management of generated electricity is paramount to ensure optimal performance and reliability. One

Mastering Inverter Basics: How Does an Inverter

Mar 26, 2024 · An inverter is a device that converts DC power to AC, and it is used for solar enery inverters, EV motors, and industrial PV inverters. Check

PV string combiner box – components and safety | Solera

Apr 2, 2025 · In photovoltaic solar installations —particularly those with multiple strings of panels— the string combiner box is a crucial component that ensures the safety, efficiency,

TECHNICAL SPECIFICATIONS OF HYBRID SOLAR PV

Feb 3, 2021 · 3. DEFINITION A Hybrid Solar PV power plant system comprises of C-Si (Crystalline Silicon)/ Thin Film Solar PV modules with intelligent Inverter having MPPT

The Basics of a PV Combiner Box: A Simple Guide for Solar

Aug 17, 2024 · To choose the right PV combiner box, it helps to understand its key parts: Fuses: These protect your system by cutting off the power if the current gets too high, preventing

How to Choose the Right Solar String Combiner

Mar 2, 2023 · After selecting solar panels, PV cables, inverters and other battery or storage devices, you don''t want to accidentally ruin your entire setup by

6 FAQs about [Basics of Photovoltaic Box Inverter]

How does a solar panel inverter work?

Its primary function is to combine the output currents of multiple solar panel strings (PV strings) into a single output, which is then sent to the inverter for DC to AC conversion. In a typical solar power system, numerous solar panels are connected in series to form multiple strings.

What is the difference between a converter box and a PV inverter?

A: A PV converter box is mainly used to collect the output current from PV cells, while a PV inverter (including grid-connected or off-grid PV inverters) converts the DC power generated by PV cells into AC power for use by the load.

What is a solar combination box?

A Solar Combiner Box is an essential electrical device used in photovoltaic (PV) power generation systems. Its primary function is to combine the output currents of multiple solar panel strings (PV strings) into a single output, which is then sent to the inverter for DC to AC conversion.

What are the different types of solar power inverters?

There are four main types of solar power inverters: Also known as a central inverter. Smaller solar arrays may use a standard string inverter. When they do, a string of solar panels forms a circuit where DC energy flows from each panel into a wiring harness that connects them all to a single inverter.

What is a photovoltaic AC combiner box?

The photovoltaic AC combiner box is used in a photovoltaic power generation system with string inverters and is installed between the AC output side of the inverter and the grid connection point/load. It is internally equipped with input circuit breakers, output circuit breakers, and AC lightning arresters.

Is a solar inverter a converter?

A solar inverter is really a converter, though the rules of physics say otherwise. A solar power inverter converts or inverts the direct current (DC) energy produced by a solar panel into Alternate Current (AC.) Most homes use AC rather than DC energy. DC energy is not safe to use in homes.

Learn More

- Photovoltaic inverter photovoltaic combiner box

- Photovoltaic station inverter and combiner box

- Is the photovoltaic inverter quick to install

- How big an inverter should I use for a 7kw photovoltaic

- Installation of courtyard photovoltaic inverter

- Energy storage inverter for photovoltaic power source

- Belize Photovoltaic Combiner Box Wholesale

- Photovoltaic combiner box power supply

- What is the voltage of photovoltaic series inverter

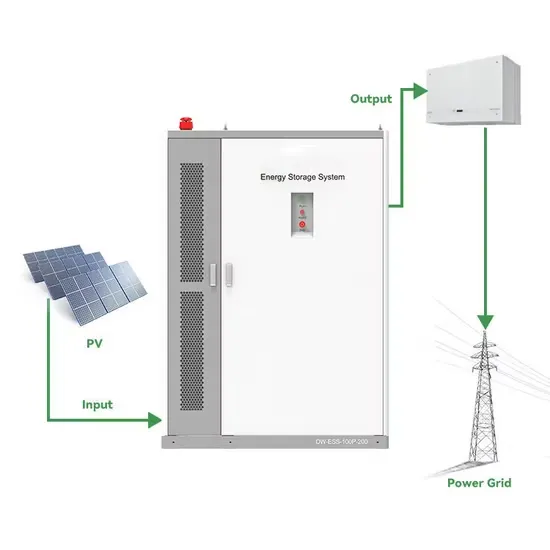

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

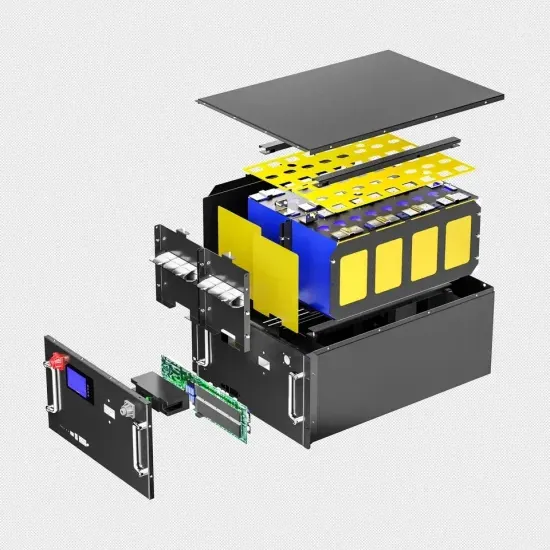

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.