Calculating Current Ratings of Photovoltaic

Nov 8, 2012 · The size of the individual cells in the module directly impact the amount of current produced; the larger the cell, the more current that can be

PV Array Voltage and Size: What You Need to Know

When building a PV array, you need a few important numbers. These numbers are your inverter''s maximum input voltage and your PV array voltage. Your PV array voltage is the total voltage

Solar Inverter String Design Calculations

Solar Inverter String Design Calculations The following article will help you calculate the maximum / minimum number of modules per series string when designing your PV system. And the

Crucial Start-Up Voltage for Solar Inverters

Sep 29, 2023 · In the realm of solar energy, where every photon of sunlight holds the promise of a cleaner, sustainable future, solar inverters play a pivotal role.

Key Inverter Parameter: Maximum PV Input Voltage

Aug 28, 2024 · The maximum PV input voltage represents the highest DC voltage that a PV inverter can safely handle. This parameter defines the upper limit for the open-circuit voltage of

Array voltage sizing according to inverter

Aug 13, 2025 · Overview Project design Grid-connected system definition Array voltage sizing according to inverter PVsyst provides a graphical tool (button Show sizing) for the study and

What Is Nominal Operating Voltage In Solar Inverter

Feb 16, 2025 · What Is Nominal Operating Voltage In Solar Inverter? Input specifications of an inverter are crucial for understanding the characteristics of the AC power it produces for

Project design > Grid-connected system definition > Array voltage

Nov 7, 2024 · - The maximum array operating voltage (i.e. at min. module operating temperature, 20°C by default) has to stay below the maximum inverter''s operating voltage (Vmax of MPPT

How to Read Solar Inverter Specifications

Nov 17, 2023 · The start-up voltage is the minimum voltage potential needed for the inverter to start functioning. For effective performance, it is recommended to confirm if the solar panel''s

SolarEdge System Design and the NEC

Nov 30, 2022 · The dc-to-dc converter in the power optimizer allows the PV module voltage and current at the converter input to be completely decoupled from (i.e. unrelated to) the converter

Solar Inverter String Design Calculations

Oct 12, 2023 · Solar Inverter String Design Calculations The following article will help you calculate the maximum / minimum number of modules per series string when designing your

Harmonics in Photovoltaic Inverters & Mitigation

Dec 22, 2022 · An inverter is an electronic device that can transform a direct current (DC) into alternating current (AC) at a given voltage and frequency. PV inverters use semiconductor

Interpreting inverter datasheet and main parameters | AE 868

Inverters are designed to operate within a voltage range, which is set by the manufacturer''s specification datasheet. In addition, the datasheet specifies the maximum voltage value of the

What Is Nominal Operating Voltage In Solar Inverter

Feb 16, 2025 · Input specifications of an inverter are crucial for understanding the characteristics of the AC power it produces for consumption. The nominal operating voltage (NOMINAL) is

PV inverter series voltage

Jul 19, 2020 · What is the difference between PV array voltage and inverter voltage? and your PV array voltage. Your PV array voltage is the total voltage of all of your modules hen connected

An Introduction to Inverters for Photovoltaic

Jun 3, 2020 · Inverters belong to a large group of static converters, which include many of today''s devices able to "convert" electrical parameters in input, such

6 FAQs about [What is the voltage of photovoltaic series inverter ]

What are the parameters of a PV inverter?

Aside from the operating voltage range, another main parameter is the start-up voltage. It is the lowest acceptable voltage that is needed for the inverter to kick on. Each inverter has a minimum input voltage value that cannot trigger the inverter to operate if the PV voltage is lower than what is listed in the specification sheet.

What parameters should be considered when stringing an inverter and PV array?

Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array. PV designers should choose the PV array maximum voltage in order not to exceed the maximum input voltage of the inverter.

What are the input specifications of a solar inverter?

The input specifications of an inverter concern the DC power originating from the solar panels and how effectively the inverter can handle it. The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

How to choose a PV array maximum voltage?

PV designers should choose the PV array maximum voltage in order not to exceed the maximum input voltage of the inverter. At the same time, PV array voltage should operate within the input voltage range on the inverter to ensure that the inverter functions properly.

What is a PV inverter?

On the other, it continually monitors the power grid and is responsible for the adherence to various safety criteria. A large number of PV inverters is available on the market – but the devices are classified on the basis of three important characteristics: power, DC-related design, and circuit topology.

How much power does a solar inverter produce?

Typical outputs are 5 kW for private home rooftop plants, 10 – 20 kW for commercial plants (e.g., factory or barn roofs) and 500 – 800 kW for use in PV power stations. 2. Module wiring The DC-related design concerns the wiring of the PV modules to the inverter.

Learn More

- What is a photovoltaic inverter with energy storage

- What is the voltage of the two sets of photovoltaic panels

- What is the voltage of a 385W photovoltaic panel

- What is the voltage of a 60v inverter

- What is the output voltage of a 335w photovoltaic panel

- Photovoltaic inverter modulation voltage bias

- What battery should be connected to the photovoltaic panel inverter

- 1500 What is the voltage of photovoltaic panels

- What is a photovoltaic inverter unit

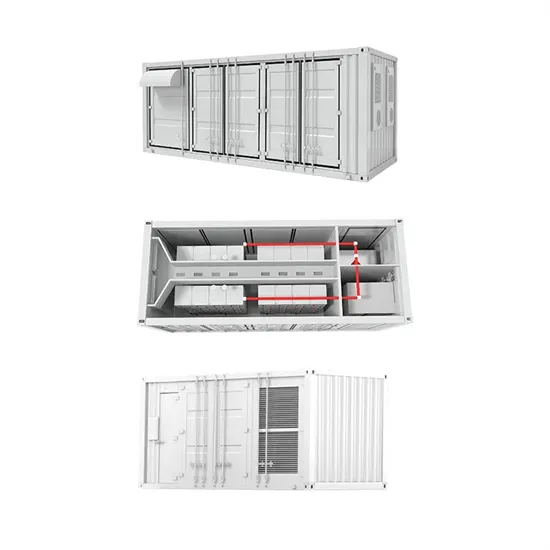

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

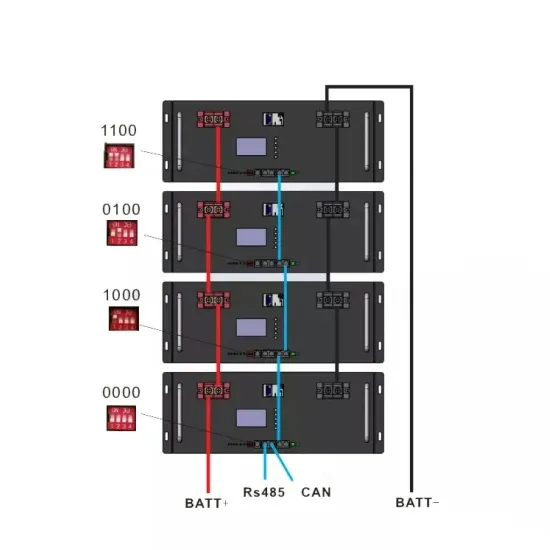

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.