Leakage Current Calculation for PV Inverter System Based on

Jan 13, 2016 · The occurrence of leakage current that can occur in photovoltaic (PV) system depends strongly on the value of parasitic capacitance between PV panel and the gro

Impedance estimation of photovoltaic modules for

Jan 11, 2018 · The capacitance is dependence on several parameter, bias voltage, frequency and temperature which not take a part in this thesis. Increase of voltage bias increase the

Technical Information

Feb 3, 2025 · 1 How is the PV Capacitance to Ground of the PV Array Calculated? A PV module forms an electrically conductive surface which stands opposite a grounded support frame. This

Leakage current measurement in transformerless

May 1, 2012 · Photovoltaic (PV) installations have seen a huge increase during the last couple of years. Transformerless PV inverters are gaining more share

ASSR-601J Insulation Resistance Measurement for

2 days ago · Introduction Transformerless photovoltaic (PV) inverter systems are getting popular these days due to lower system cost, higher efficiency, easier installation and maintenance.

Impedance estimation of photovoltaic modules for

Apr 9, 2019 · In this work, the start-up current and voltages are measured experimentally for different parallel and series connections of the PV modules. These measurements are used to

DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

Fault detection and diagnosis methods for photovoltaic

Aug 1, 2018 · Faults in any components (modules, connection lines, converters, inverters, etc.) of photovoltaic (PV) systems (stand-alone, grid-connected or hybrid PV systems) can seriously

Modelling of Photovoltaic (PV) Inverter for Power

Feb 4, 2019 · An extensive literature review is conducted to investigate various models of PV inverters used in existing power quality studies. The two power quality aspects that this study

Methods for measuring capacitance of photovoltaic inverters

Accurate Power Measurements of High Capacitance PV A method for measuring accurately and rapidly the current-voltage characteristics of high-capacitance photovoltaic devices using

Modeling the Frequency Response of Photovoltaic

Feb 4, 2019 · Abstract—The increased presence of photovoltaic (PV) systems inevitably affects the power quality in the grid. This new reality demands grid power quality studies involving PV

Moisture Ingress Models of Film Capacitors in PV Inverters

Aug 24, 2022 · FTIR Analysis • Capacitor samples were desoldered from the inverter device under test. Capacitors were mechanically sawed off and visually examined to understand

Photovoltaic inverter resistance measurement

in PV inverters. It can also be used to arrive at a detailed modelling of PV modules to evaluate the transient behaviour. Keywords. Photovoltaic module; dynamic model; solar cell capacitance;

MONITORING THE MOISTURE INGRESS INTO PV

Sep 9, 2020 · ABSTRACT: We are presenting an approach for the monitoring of the parasitic capacitance of PV modules as an indication for moisture ingress into the polymers during

PowerPoint Presentation

Oct 20, 2021 · The AC output filter is a low pass filter (LPF) that blocks high frequency PWM currents generated by the inverter. Three phase inductors and capacitors form the low pass

Selection and calculation of dclink capacitor in

Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic systems and needs effort to design a reliable and optimal size capacitor as its reliability is

Analysis of Leakage Current and DC Injection in

Jan 8, 2015 · However, transformerless inverters have a serious drawback of ground leakage current which flows between the PV array and the ground through the parasitic capacitance

Specifying Insulation Monitoring Devices for

Sep 22, 2016 · In her recent post, " Ground Fault Protection for Utility-Scale Solar Arrays," my colleague Vanya Ignatova covered some of the basics to consider

The effect of capacitance on high-efficiency

Feb 25, 2021 · While the cell diffusion capacitance is a physical property of the solar cell, the cell effective capacitance defined in (7) is a parameter having

How to measure capacitance on photovoltaic panels

This work summarizes the basic physics behind the effect of capacitance on the electrical characterization of silicon PV modules, with the simplest approach of a single diode

Methods for measuring capacitance of photovoltaic

What is PV cell capacitance measurement? Photovoltaic(PV) cell capacitance measurement has drawn attention of researchers in recent times owing to the importance of dynamically

Leakage Current Calculation for PV Inverter System Based on

Jan 13, 2016 · The occurrence of leakage current that can occur in photovoltaic (PV) system depends strongly on the value of parasitic capacitance between PV panel and the ground.

Selecting and Applying DC Link Bus Capacitors for

May 16, 2023 · Sam G. Parler, Jr., P.E. Cornell Dubilier Abstract, aluminum electrolytic and DC film capacitors are widely used in all types of inverter power systems, from variable-speed

Selecting an Isometer for use with SolarEdge Inverters

Nov 30, 2022 · 2 Minimum Alarm Threshold In many locations the ground can contain varying degrees of moisture, a factor that is known to increase capacitance levels. SolarEdge

Photovoltaic inverter resistance measurement method

The steady increase in photovoltaic (PV) installations calls for new and better control methods in respect to the utility grid connection. Limiting the harmonic distortion is The proposed

An on-Line Extraction Method for the Parasitic

Dec 30, 2019 · The existing on-line capacitance measurement method is to measure the amplitude of the main components of voltage and current on the capacitance, but the

6 FAQs about [Photovoltaic inverter capacitance measurement]

What is a capacitor in a PV device?

The capacitor represents the accumulation of charges in the PV device. The capacitance of a PV device is attributed to both junction capacitance and diffusion capacitance, both of which are voltage dependent.

Does solar cell capacitance affect electrical characterization of photovoltaic (PV) modules?

The effect of solar cell capacitance in the electrical characterization of photovoltaic (PV) modules at Standard Test Conditions (STC) is known since the 1990s.

Why do PV modules always exhibit capacitance?

The way PV modules are designed means that they always exhibit capacitance towards their environment. This capacitance is not required for the function of the PV array, but comes about essentially from the mechanical structure of the modules and their installation, and is therefore also known as "parasitic" capacitance.

Does parasitic capacitance affect leakage current in photovoltaic system?

Abstract: The occurrence of leakage current that can occur in photovoltaic (PV) system depends strongly on the value of parasitic capacitance between PV panel and the ground. However, traditional method to acquire that value is by experience estimation.

What is the critical capacitance to ground of a PV module?

The PV module under review exhibits a high design-related capacitance to ground CPE (laminate, integrated metal rear panel), or it is necessary to reliably prevent feed-in interruptions due to rain/condensation. Determine the critical capacitance to ground as follows: Calculate the total module surface of the modules connected to one inverter.

Does parasitic capacitance affect the insulation of PV modules?

This phenomenon does not affect the insulation of the PV modules in any way, so personal safety is of course guaranteed at all times. However, the operating behavior of the inverters may be influenced by parasitic capacitance.

Learn More

- Photovoltaic station inverter and combiner box

- Safety photovoltaic inverter

- South Korea Photovoltaic Energy Storage Inverter

- How many photovoltaic inverter companies are there

- Shangneng String Photovoltaic Inverter

- How much does a Sanaa photovoltaic inverter cost

- Photovoltaic grid-connected inverter igbt

- Inverter Photovoltaic System Design

- Huawei North Asia Photovoltaic Inverter Factory

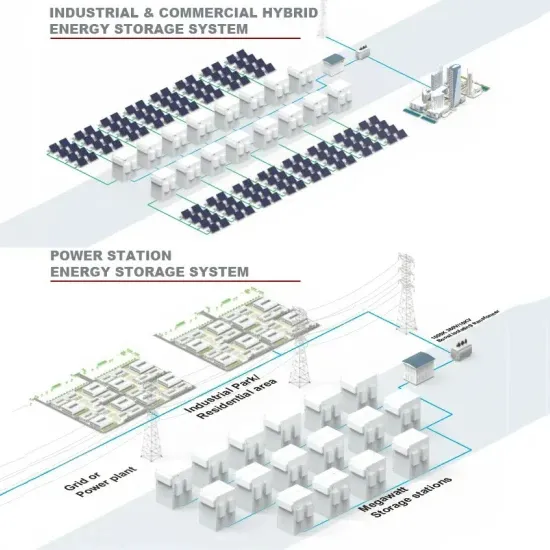

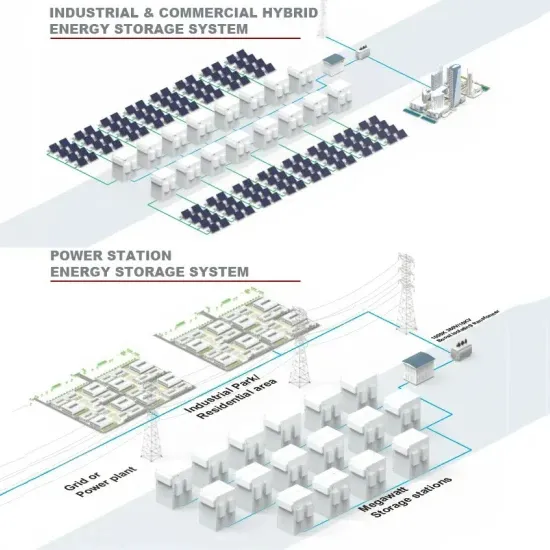

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.