Communication Base Station Innovation Trends | HuiJue

Rethinking Infrastructure for the 5G-Advanced Era As global mobile data traffic surges 35% annually, communication base stations face unprecedented demands. Can traditional tower

Compliance requirements for inverters and communication

May 20, 2025 · ) F.No. 318/87/2024-GCRT -Part (1) Government of India Ninistry of New and Renewable Energy PMSG: MBY Division Atal Akshay Urja Bhawan Lodhi Road, New Delhi

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

TYPE ACCEPTANCE CRITERIA FOR

Oct 8, 2012 · This document sets out the technical criteria for type acceptance of Base Station Equipment (hereafter referred to as "the equipment") for use in the 3G Mobile Communications

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

IEC and European Inverter Standards, Baltimore High

Dec 12, 2005 · The standard defines the requirements for an automatic AC disconnect interface – it eliminates the need for a lockable, externally accessible AC disconnect. When will PV be

Inverter communication mode and application scenario

Jul 15, 2025 · When using GPRS/4G communication mode, each inverter needs to be equipped with a data collector with GPRS/4G communication module, built-in SIM card or use an

CHINA ELECTRIC POWER RESEARCH INSTITUTE

Jan 1, 2013 · NB/T 32008-2013 Testing code for power quality of inverters used in photovoltaic power station GB/T31365-2015 Testing code for photovoltaic power station connected to

SpecificationsforGrid-forming Inverter-basedResources

Sep 12, 2023 · ric grids alongside rotating machines and other IBRs. This document defines a set of UNIFI Specifications for GFM IBRs that provides requirements from both a power system

Research on Automatic Acceptance Technology of OCS Main Station

May 1, 2021 · Substation automation is based on the user terminal project, and the acceptance requirements will be based on the operation, coordination, scheduling, measurement and

NB-IoT Base Station acceptance test is a first

With growing demand for LPWA (Low Power Wide Area) services and applications as part of the Internet of Things (IoT), 3GPP has developed Narrow Band IoT (NB-IoT) as a new cellular air

CSIP Implementation Guide v2.0

Mar 17, 2025 · All smart inverters require communications to achieve their full value as distributed energy resources. Establish a complete profile – To achieve complete interoperability a

Evaluation of communication requirements for voltage

Sep 20, 2016 · Evaluation of communication requirements for voltage regulation control with advanced inverters Published in: 2016 North American Power Symposium (NAPS) Article #:

Design and realization of 5G mobile base station s

Feb 28, 2024 · The research work of this program design has basically reached the expected requirements, through the user requirements analysis, functional design, database design,

TYPE ACCEPTANCE CRITERIA FOR

Nov 11, 2020 · This document sets out the technical criteria for type acceptance of Base Station Equipment (hereafter referred to as "the equipment") for use in the 3G Mobile Communications

TYPE ACCEPTANCE CRITERIA

Oct 8, 2012 · This document sets out the technical criteria for type acceptance of Base Station (BS) equipment (hereafter referred to as "the equipment") for use in the Public Mobile

Grid Connection Acceptance of Photovoltaic Power Station

The purpose of acceptance is to verify whether the construction quality of photovoltaic power station and the performance of key components meet the requirements of relevant standards;

Datong Leader Base Acceptance Test Wins the Award for the

May 21, 2017 · According to regulations, inverter products used in the leader project require that the annual production capacity of the enterprise inverter is not less than 200MW, the efficiency

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · The PV Module should be under the Indigenous / DCR (Domestic Content Requirement) category (Based on the specific requirement). The PV modules shall conform to

Photovoltaics International Grid connection

May 21, 2024 · Grid connection requirements and test procedures: Experiences in the certification process of PV inverters Dominik Geibel, Dr. Gunter Arnold & Dr. Thomas Degner, Fraunhofer

Hybrid Power Supply System for Telecommunication Base Station

Jul 1, 2018 · The most energy-intensive part of cellular communications is the base station, which there are about four million of them deployed globally.

Datong Leader Base Acceptance Test Wins the Award for the

May 21, 2017 · Among the 1 million-kilowatt projects that have been connected to the grid, the equipment selected by the Datong base has met or exceeded the technical index

Simulation and Classification of Mobile Communication Base Station

Dec 16, 2020 · In recent years, with the rapid deployment of fifth-generation base stations, mobile communication signals are becoming more and more complex. How to identify and classify

Photovoltaic inverter installation acceptance

Basic solar inverter quality Inverter Acceptance Inverters are key devices that convert direct current (DC) to alternating current (AC) in a PV system. Acceptance involves verifying the

6 FAQs about [Acceptance requirements for communication base station inverters]

Do smart inverters need communication?

All smart inverters require communications to achieve their full value as distributed energy resources. Establish a complete profile – To achieve complete interoperability a complete profile is required including a data model, messaging model, communication protocol and security.

What are the characteristics of different communication methods of inverters?

The characteristics of different communication methods of inverters are obvious, and the application scenarios are different. In order to better weave the underlying network of energy digitization and intelligent development, choose the most appropriate communication method according to local conditions.

What should be considered when choosing a GFM inverter?

should consider the ratings of the GFM IBRs utilized. The speed of response may be constrained by the basic limitations of the DC source behind the GFM inverter. For example, a wind turbine’s speed of response o frequency variations in the grid may be slower than

Who manages underlying inverters?

It is the 181 responsibility of the aggregator system to manage the underlying inverters to meet the requirements of 182 the settings provided by the utility server. The specific interpretation of the DER being a single entity or 183 a related group is established at the time of interconnection with the utility. 2.

Can DS be updated to fully account for GFM inverters?

ds can be updated to fully account for GFM inverters. For example, a GFM IBR should not necessarily be expected to exhibit the same level of performance as a GFL IBR in the fast restoration of active and/or reactive power immediately after a major grid event, since a GFL IBR has a natural advantage over GFM IBR in the p

Can grid-forming inverters be integrated?

r system operation with grid-forming (GFM) resources. In some cases, those requirements may not be appropriate for or ay even inadvertently limit the use of GFM resources. The UNiversal Interoperability for grid-Forming Inverters (UNIFI) Consortium is addressing funda-mental challenges facing the integration of GFM inverters in elec

Learn More

- Requirements for direct supply of communication base station inverters

- Base station communication power supply requirements and specifications

- Communication Green Base Station Network Cable Requirements

- What communication base station inverters are connected to the grid in Kazakhstan

- What are the technical specifications for grid-connected operation and maintenance of communication base station inverters

- Temperature and humidity requirements for grid-connected inverters for communication base stations

- Panama s first 5G communication base station

- Uninterruptible power supply equipment for Nuku alofa communication base station

- Sri Lanka small communication base station flywheel energy storage

Industrial & Commercial Energy Storage Market Growth

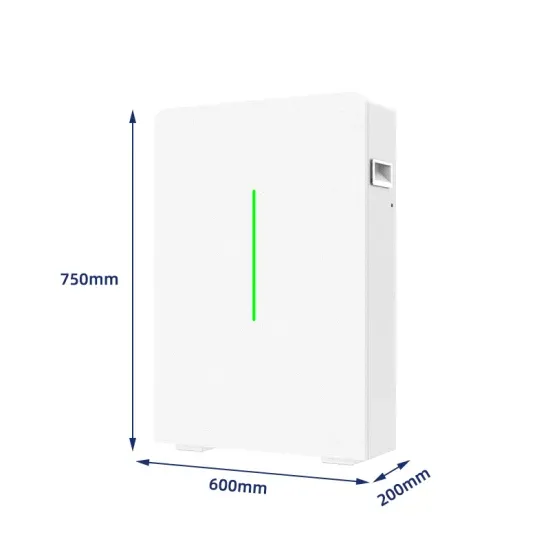

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.