ENERGY STORAGE

Jan 30, 2024 · Identify suitable applications and locations for hydrogen storage deployment in Sri Lanka, considering factors such as the availability of renewable energy resources, existing

Sri Lanka Flywheel Energy Storage Systems Market (2025

Market Forecast By Type (Low-Speed Flywheel, High-Speed Flywheel, Hybrid Flywheel, Superconducting Flywheel), By Material (Carbon Fiber, Steel, Composite, Alloy), By

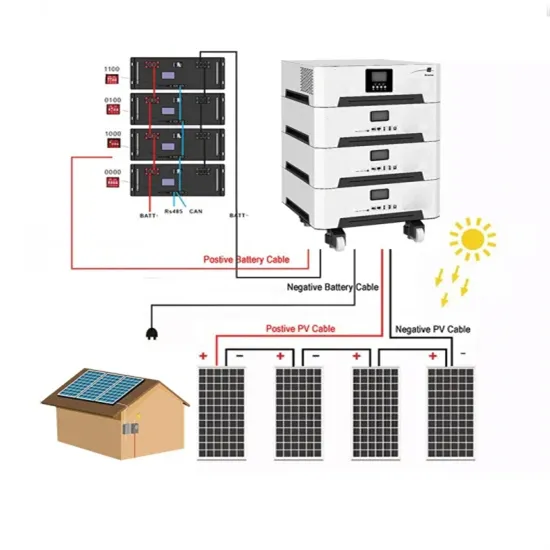

Energy Storage Equipment, Energy storage solutions,

Huijue Group''s energy storage solutions (30 kWh to 30 MWh) cover cost management, backup power, and microgrids. To cope with the problem of no or difficult grid access for base stations,

(PDF) Energy Storage Solutions for Sri Lanka

Feb 23, 2025 · To address these issues, the report evaluates the potential of three key energy storage technologies: Pumped Energy Storage Systems (PESS), Thermo-mechanical Energy

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

Sri Lanka Flywheel Energy Storage Market (2024-2030)

How does 6W market outlook report help businesses in making decisions? 6W monitors the market across 60+ countries Globally, publishing an annual market outlook report that

Modeling and Control of Flywheel Energy Storage System

May 15, 2023 · Flywheel energy storage has the advantages of fast response speed and high energy storage density, and long service life, etc, therefore it has broad application prospects

Energy storage system of communication base station

The Energy storage system of communication base station is a comprehensive solution designed for various critical infrastructure scenarios, including communication base stations, smart

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

China Connects Its First Large-Scale Flywheel Storage Project

Sep 14, 2024 · China has connected to the grid its first large-scale standalone flywheel energy storage project in Shanxi Province''s city of Changzhi. The Dinglun Flywheel Energy Storage

Flywheel Energy Storage: Challenges in Microgrids

Feb 15, 2024 · While flywheel energy storage systems offer several advantages such as high-power density, fast response times, and a long lifespan, they also face challenges in microgrid

Presented our research on frictionless flywheel energy storage

I'm proud to share that I recently presented our team''s first international conference abstract at the International Conference on University-Industry Collaborations for Sustainable

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

A Comprehensive Overview of Sri Lanka''s Pumped

Apr 16, 2023 · Abstract: Pumped hydro storage (PHS) is a well-established technology for storing energy in large quantities and over long periods. Sri Lanka, a country rich in hydropower

Understanding Energy Storage Systems (ESS) in Sri Lanka:

Jun 17, 2025 · This article explores what ESS is, why it''s relevant for Sri Lanka, and how businesses and homeowners can benefit from integrating storage into their energy systems.

Flywheel energy and power storage systems

Feb 1, 2007 · Small-scale flywheel energy storage systems have relatively low specific energy figures once volume and weight of containment is comprised. But the high specific power

Grid-Scale Flywheel Energy Storage Plant

Dec 7, 2012 · Demonstrating frequency regulation using flywheels to improve grid performance Beacon Power will design, build, and operate a utility-scale 20 MW flywheel energy storage

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

6 FAQs about [Sri Lanka small communication base station flywheel energy storage]

What is a flywheel energy storage system?

A typical flywheel energy storage system , which includes a flywheel/rotor, an electric machine, bearings, and power electronics. Fig. 3. The Beacon Power Flywheel , which includes a composite rotor and an electric machine, is designed for frequency regulation.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research , studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

What is a beacon power flywheel?

The Beacon Power Flywheel , which includes a composite rotor and an electric machine, is designed for frequency regulation. Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

What are flywheel systems used for?

Almost all the existing flywheel systems are designed for specific applications such as frequency regulation or UPS. They require specialized knowledge and techniques for manufacture, assembly, and maintenance, which prevents them from being produced in large quantities to reduce cost per unit.

Learn More

- Communication base station flywheel energy storage construction order

- 5g communication base station flywheel energy storage construction

- Communication base station flywheel energy storage kw

- Communication base station flywheel energy storage 19

- Obstructing communication base station flywheel energy storage

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- How to build a flywheel energy storage project for a communication base station

- Installation of flywheel energy storage equipment for Manama communication base station

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

Industrial & Commercial Energy Storage Market Growth

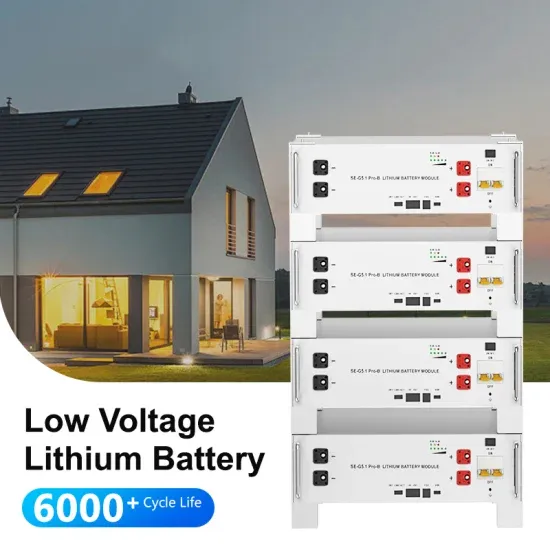

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.