Redox flow batteries based on insoluble redox-active materials. A

Mar 1, 2021 · At present, three types of insoluble flow batteries have been explored: slurry-based flow batteries, metal/slurry hybrid, and redox-mediator-assisted flow batteries. This Review

Lithium-based vs. Vanadium Redox Flow Batteries

Nov 1, 2016 · Due to superior performance and significant price degression, lithium ion batteries (LiBs) are the dominating technology in this market. However, in 2015, a new technology

High-energy and low-cost membrane-free chlorine flow battery

Mar 11, 2022 · Flow batteries provide promising solutions for stationary energy storage but most of the systems are based on expensive metal ions or synthetic organics. Here, the authors

From laboratory innovations to materials manufacturing for lithium

Mar 30, 2023 · With a focus on next-generation lithium ion and lithium metal batteries, we briefly review challenges and opportunities in scaling up lithium-based battery materials and

Life cycle assessment (LCA) for flow batteries: A review of

Oct 1, 2022 · Flow batteries are seen as one promising technology to face this challenge. As different innovations in this field of technology are still under development, reproducible,

Perspectives on zinc-based flow batteries

Jun 17, 2024 · Most importantly, the feasibility and practicality of a zinc-based flow battery system should be taken into consideration. Overall, benefiting from the above features, the zinc-based

Comparing Lithium-ion and Flow Batteries for Solar Energy

Mar 20, 2025 · Lithium-ion batteries and flow batteries differ primarily in their energy storage mechanisms and applications. Lithium-ion batteries store energy chemically within solid

Slurry Based Lithium-Ion Flow Battery with a Flow Field

Jun 28, 2023 · Slurry based lithium-ion flow battery has been regarded as an emerging electrochemical system to obtain a high energy density and design flexibility for energy

(PDF) Comparative analysis of lithium-ion and

Mar 18, 2024 · Flow batteries have a competitive advantage in terms of cycle life, providing a longer duration of 1000 cycles compared to Lithium-ion batteries,

Optimization design of flow path arrangement and channel

Apr 1, 2025 · Optimization design of flow path arrangement and channel structure for lithium-ion battery cooling plate based on the three-field synergy principle

Redox targeting-based flow batteries

Aug 13, 2019 · Particularly, based on the redox targeting concept, redox targeting-based flow batteries are extensively discussed as a novel flow battery technology for high-density energy

Semi-solid lithium/oxygen flow battery: an emerging, high

Sep 1, 2022 · Lithium-Air (O 2) batteries are considered one of the next-generation battery technologies, due to their very high specific energy. In parallel, Redox Flow Batteries (RFBs)

Organic Redox Flow Batteries: Lithium-Ion-based FB s

Jan 6, 2023 · Lithium-Ion-based FB, which uses the Li + ion as charge carrier, semi-solid or solid-phase Li-host materials as energy storage media, represents a promising strategy to

Redox flow batteries: Status and perspective towards

Jan 1, 2021 · The single flow media-single circulation approach stands as the most popular including both aqueous based zinc air flow batteries (Zn-MAFBs) and non-aqueous lithium air

Recent development of electrode materials in semi-solid lithium

Jan 15, 2024 · Semi-solid lithium redox flow batteries (SSLRFBs) have gained significant attention in recent years as a promising large-scale energy storage solution due to their scalability, and

6 FAQs about [Lithium-based flow battery]

Are lithium-based semi-solid flow batteries suitable for large-scale energy storage?

Abstract: Semi-solid flow battery(SSFBs) is a critical technology for large-scale energy storage due to their promising characteristics of high energy density and design flexibility. Recently, tremendous research efforts have been made to design lithium-based SSFBs(Li-SSFBs).

What is a slurry based lithium-ion flow battery?

A slurry based lithium-ion flow battery is a type of battery that uses a liquid slurry of lithium iron phosphate (LiFePO4 or LFP) as its electrolyte. This battery features a serpentine flow field and a porous carbon felt electrode design. The schematic illustration shows an example of this concept using LFP slurry.

Can a slurry based lithium-ion flow battery improve design flexibility?

A slurry based lithium-ion flow battery is proposed in this work, featuring a serpentine flow field and a stationary porous carbon felt current collector. This design aims to improve the design flexibility by decoupling the electrode thickness and flow resistance.

What is a lithium-extraction redox flow battery (Le-RFB)?

The lithium-extraction redox flow battery (LE-RFB) extracts dissolved lithium with a purity of 93.5% from simulated seawater, corresponding to a high Li/Mg selectivity factor of about 500.000:1. Benefiting from a low operating voltage, 1 g of lithium is extracted with only 2.5 Wh of energy consumption. Copyright © 2022 American Chemical Society

Are flow batteries better than Lib batteries?

Several manufacturers are now offering flow batteries in the required scale. This technology has low variable costs (€/kWh) and uses a wider SoC range. On the other hand, efficiency is lower than for the LiB and fixed costs (€/kW) are rather high.

How does a slurry based flow battery work?

In a slurry based flow battery, the flow of slurry along the carbon felt surface prevents particles from accumulating and forming a thick filter cake. This minimizes the risk of fouling and clogging, allowing for a relatively stable operation.

Learn More

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- Flow battery skills and applications

- Sodium flow battery energy storage

- Is flow battery a new energy source

- Communication base station flow battery technology and management

- Iron-based liquid flow battery energy storage system

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Africa s new all-vanadium liquid flow battery

- Nigeria s new all-vanadium flow battery

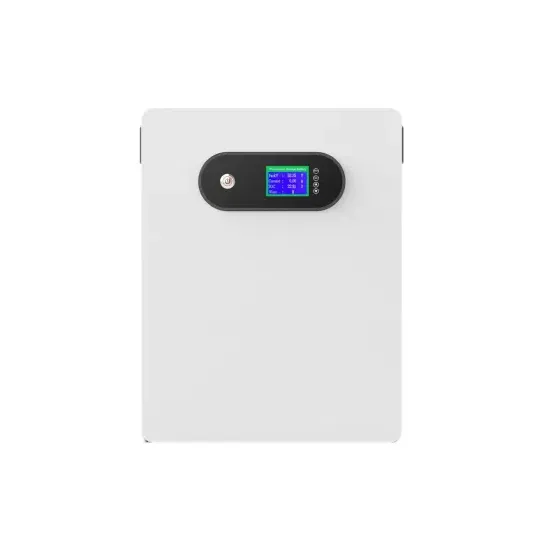

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.