What are the modules of the South Tarawa

The proposed South Tarawa Renewable Energy Project will install solar photovoltaic and battery energy storage system to help the government achieve its renewable energy target for South

What is Box-type substation and its function

What is a Box-type Substation? Box-type Substation, also known as prefabricated substation or combined substation, is a small substation that assembles high-voltage switchgear,

South Tarawa Energy Storage Station Project Time

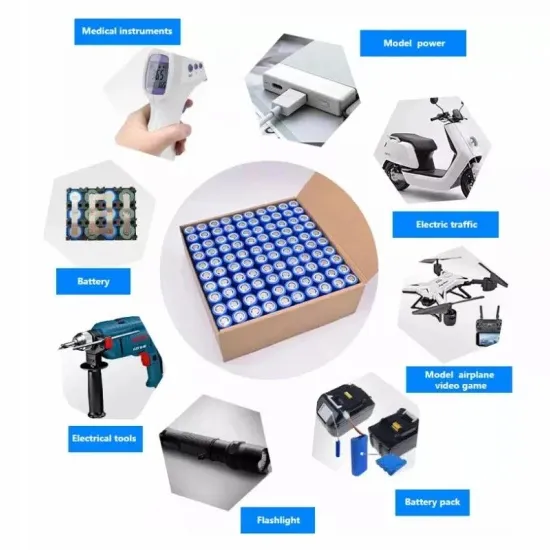

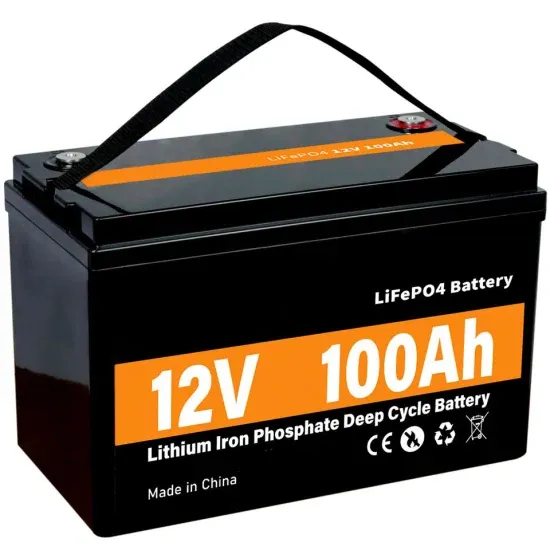

South Tarawa New Energy Extended Range Battery Cabinet Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion

Substation Primary Design Standard

Aug 12, 2022 · The substation design responsibilities are broadly divided into primary and secondary systems. The primary systems are the high voltage, civil and structural and building

Communication in substation automation systems

Jan 11, 2020 · Station bus exists at the substation level and is used for communication between IEDs at the bay level and the station level. Several redundancy methodologies are usually

Microsoft Word

May 9, 2008 · Communication plays a vital role in automation & control in a substation. We have to collect information from the utility and exchange that information with the Master station in

South Tarawa Renewable Energy Project: Climate

Feb 4, 2023 · In South Tarawa rainfall is highly influenced by the ENSO events. Annual average rainfall is higher than 1,800 mm according to the multiple data sources analysed. Monthly

South Tarawa New Energy Storage Power Station

Does South Tarawa need solar power? Constrained renewable energy development and lack of private sector participation. While grid-connected solar power is the least-cost renewable

South Tarawa Energy Storage Charging Station

Economic Feasibility of Hybrid Solar-Powered Charging Station with Battery Energy Storage System in Thailand May 2023 International Journal of Energy Economics and Policy 13(3):342

How to Design and Install Substation Control Panels

Jan 26, 2025 · Designing and installing substation control panels is a complex but critical process that ensures reliable and safe substation operations. By carefully planning the design,

Smart Power of Communication Base Station

Installing a smart switch module at an unattended basic station, the smart switch module can collect data in real time and use the data to display on a visual management platform to help

The IDC Engineers Pocket Guide Chapter 3 Substation

Nov 22, 2021 · Definition of the Term Substation Automation can be defined as a system for managing, controlling and protecting a power system. This is accomplished by obtaining real

Communication in substation automation systems

Jan 11, 2020 · The success of a substation protection and automation system relies on the use of an effective communication system, incorporating state-of-the-art information and

South Tarawa Battery Box Company Directory Announcement

South Tarawa South Tarawa is the capital and hub of the Republic of Kiribati and home to more than half of Kiribati''''''''s population. The South Tarawa population centre consists of all the small

Hope Radio goes to air in Kiribati – Adventist

Nov 23, 2018 · The South Pacific''s newest Adventist Hope radio station has hit the airwaves, aimed at sharing the good news about Jesus with the residents

Fundamentals of Modern Electrical Substations

Mar 16, 2023 · Part 1 of this course series is concentrated on demonstrating how modern power systems are arranged to accomplish all these goals; what place electrical substations have in

Electrical Substation: Equipment, Types, Components

An electrical substation is an integral part of a generation, transmission and distribution system. A substation can interrupt or establish electrical circuit, change the voltage, frequency or other

6 FAQs about [South Tarawa Communication Base Station Box Substation]

How do substations communicate?

Effective communication in substations relies heavily on standardized protocols. These protocols ensure interoperability between devices from different manufacturers and facilitate efficient data exchange. Go here to learn more about DNP3. 4. Fiber Optic Communication Fiber optic cables are the backbone of modern substation communication systems.

How does a substation protection and automation system work?

The success of a substation protection and automation system relies on the use of an effective communication system, incorporating state-of-the-art information and communication technologies, to link various protection, control, and monitoring devices within an electric power substation .

What are substation design responsibilities?

The substation design responsibilities are broadly divided into primary and secondary systems. The primary systems are the high voltage, civil and structural and building elements. The secondary systems are the protection, communication and control, auxiliary supplies and the automation systems that integrate the operation of the substation.

What are the secondary systems of a substation?

The secondary systems are the protection, communication and control, auxiliary supplies and the automation systems that integrate the operation of the substation. This document deals with the design of the primary system of the substation. 2. Reference Documentation 3. Safety in Design

What equipment does a substation need?

Explore essential communication equipment for substations, including RTUs, PLCs, fiber optic and wireless solutions. Learn about key protocols like DNP3, IEC 61850, and Modbus for efficient and reliable substation operations. Discover recommended products to enhance your substation's communication capabilities.

What are the communication needs and requirements of each substation level?

The communication needs and requirements of each substation level vary according to the type of data and its size. Communication requirements are of different types like Real-time operational data communication that includes power system control, have “hard” real time requirements.

Learn More

- South Tarawa communication base station development

- South Tarawa Communication 5G Base Station Construction Project

- Battery room optical exchange box for communication base station

- South Sudan s communication base station wind and solar hybrid power

- How to install the aluminum box of lithium-ion battery in communication base station

- What is in a communication base station uninterruptible power supply

- Communication base station inverter method

- Communication 5g and 5g base station

- How to sell Huawei base station communication equipment

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.