Research of critical causes and improvement of energy storage

Mar 30, 2017 · In order to prevent the critical failures in lead acid batteries, the authors propose a new multistep current charge profile based on mathematical methods to calculate the charge

Life Cycle Assessment (LCA)-based study of the

Feb 1, 2021 · Lead-acid batteries are the most widely used type of secondary batteries in the world. Every step in the life cycle of lead-acid batteries may

Thermodynamics of Lead-Acid Battery Degradation

Dec 19, 2019 · Aging mechanisms include sulfation on the negative electrode, water loss due to gassing and evaporation, expansion of the positive electrode, acid stratification and grid

Battery energy storage systems and SWOT (strengths,

Sep 1, 2022 · There are comparative charts with many features of each storage technique provided and descriptions of the various uses of energy storage methods. Furthermore, The

Lead-acid Battery Degradation Mechanisms in Photovoltaic Systems

Oct 21, 2013 · Considered a mature and initial low cost technology, lead-acid battery technology is well understood and found in a wide range of photovoltaic (PV) energy storage applications.

Lead-Acid Batteries: The Cornerstone of Energy Storage

The mainstay of energy storage solutions for a long time, lead-acid batteries are used in a wide range of industries and applications, including the automotive, industrial, and residential

Lead batteries for utility energy storage: A review

Jul 13, 2017 · In the very early days of the development of public electricity networks, low voltage DC power was distributed to local communities in large cities and lead–acid batteries were

Failure modes of lead/acid batteries

Dec 16, 1991 · The delivery and storage of electrical energy in lead/acid batteries via the conversion of lead dioxide and lead to, and from, lead sulphate is deceptively simple. In fact,

Advanced Analysis of Lead-Acid Batteries

Dec 10, 2022 · 1 Abstract Since their invention in 1859, lead-acid batteries have been used in automobiles, and in emergency and power-storage batteries. The market for these batteries

Thermodynamics of Lead-Acid Battery Degradation

Dec 19, 2019 · Availability, safety and reliability issues—low specific energy, self-discharge and aging—continue to plague the lead-acid battery industry, 1 – 6 which lacks a consistent and

Lead Acid Battery for Energy Storage Market Size And

Jul 21, 2025 · The global lead acid battery for energy storage market size was valued at $7.36 Bn in 2019 & is projected to reach $11.92 Bn by 2032,at a CAGR of 3.82% during 2020-2032

Advanced Lead–Acid Batteries and the Development of Grid-Scale Energy

May 1, 2014 · This paper discusses new developments in lead-acid battery chemistry and the importance of the system approach for implementation of battery energy storage for

A comparative life cycle assessment of lithium-ion and lead-acid

Jul 15, 2022 · The sensitivity analysis shows that the use-phase environmental impact decreases with an increase in renewable energy contribution in the use phase. The lithium-ion batteries

Advances and challenges in improvement of the

Feb 1, 2022 · Abstract With the progress of science and technology and the needs of the development of human society, lead-acid batteries (LABs) have attracted the attention of

Lead-Carbon Batteries toward Future Energy Storage:

Sep 19, 2022 · Despite the wide application of high-energy-density lithium-ion batteries (LIBs) in portable devices, electric vehicles, and emerging large-scale energy storage appli-cations,

Techno-economic analysis of lithium-ion and lead-acid

Researchers have investigated the techno-economics and character-istics of Li-ion and lead-acid batteries to study their response with different application profiles [2-5]. The charge and

Energy storage system: Current studies on batteries and power

Feb 1, 2018 · The paper summarizes the features of current and future grid energy storage battery, lists the advantages and disadvantages of different types of batteries, and points out

Understanding Sulfation and Recovery in Lead Acid

Apr 16, 2024 · During discharge, both plates convert to lead sulfate (PbSO4) and the electrolytes becomes less acidic. This reduces the specific gravity of the solution, which is the chemical

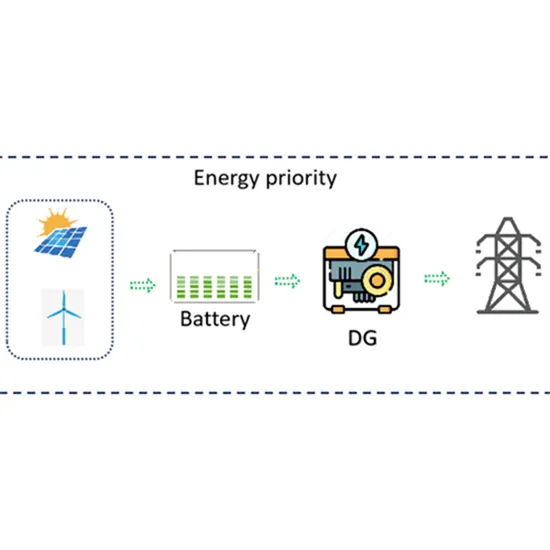

A COMPREHENSIVE REVIEW OF INTEGRATED ENERGY

Sep 29, 2024 · Abstract. The integration of energy storage batteries into renewable energy stations is a crucial development in the quest for sustainable and reliable energy solutions.

Identification and remediation of sulfation in lead-acid batteries

Jan 1, 2013 · The operating environment, manufacturing variability, and use can cause different degradation mechanisms to dominate capacity loss inside valve regulated lead-acid (VRLA)

Battery Hazards for Large Energy Storage Systems

Jul 25, 2022 · Battery technologies currently utilized in grid-scale ESSs are lithium-ion (Li-ion), lead–acid, nickel–metal hydride (Ni-MH), nickel–cadmium

A Review of the Positive Electrode Additives in Lead-Acid

Feb 12, 2018 · It is widely used in various energy storage systems, such as electric vehicles, hybrid electric vehicles, uninterruptible power supply and grid-scale energy storage system of

Advanced Analysis of Lead-Acid Batteries

Dec 10, 2022 · In this research work, we newly developed the following multiple analytical methods enabling in situ observation and quantifi-cation of 2D- and 3D-nanostructure, crystal

Economic evaluation of batteries planning in energy storage power

Jun 1, 2015 · When constructing energy storage power stations with lead-acid batteries, lithium-ion batteries and VRBs as alternative batteries, the configuration of 7.13 MWh of lithium-ion

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Lead–acid batteries are supplied by a large, well-established, worldwide supplier base and have the largest market share for rechargeable batteries both in terms of sales value

Comprehensive review of energy storage systems

Jul 1, 2024 · Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

Modeling transient processes in lead-acid batteries in the

Jun 1, 2020 · In stationary application of lead-acid batteries the focus shifts from UPS to photovoltaic storage and grid service functions. For the battery this means changing from a

Lead-acid battery use in the development of renewable energy systems

Jun 1, 2009 · The development of safe, long-life, high-efficiency, low-priced energy storage systems is therefore a high priority. Lead-acid batteries with their advantages of low price, high

6 FAQs about [Analysis of the causes of power storage in lead-acid batteries in base stations]

Can lead-acid battery chemistry be used for energy storage?

Abstract: This paper discusses new developments in lead-acid battery chemistry and the importance of the system approach for implementation of battery energy storage for renewable energy and grid applications.

What is lead acid battery?

It has been the most successful commercialized aqueous electrochemical energy storage system ever since. In addition, this type of battery has witnessed the emergence and development of modern electricity-powered society. Nevertheless, lead acid batteries have technologically evolved since their invention.

Are lead acid batteries suitable for solar energy storage?

Solar Energy Storage Options Indeed, a recent study on economic and environmental impact suggests that lead-acid batteries are unsuitable for domestic grid-connected photovoltaic systems . 2.Introduction Lead acid batteries are the world's most widely used battery type and have been commercially deployed since about 1890.

Does stationary energy storage make a difference in lead–acid batteries?

Currently, stationary energy-storage only accounts for a tiny fraction of the total sales of lead–acid batteries. Indeed the total installed capacity for stationary applications of lead–acid in 2010 (35 MW) was dwarfed by the installed capacity of sodium–sulfur batteries (315 MW), see Figure 13.13.

Why is the lead-acid battery industry failing?

Availability, safety and reliability issues—low specific energy, self-discharge and aging—continue to plague the lead-acid battery industry, 1 – 6 which lacks a consistent and effective approach to monitor and predict performance and aging across all battery types and configurations.

Can lead batteries be used for energy storage?

Lead batteries are very well established both for automotive and industrial applications and have been successfully applied for utility energy storage but there are a range of competing technologies including Li-ion, sodium-sulfur and ow batteries that are used for energy storage.

Learn More

- Replacing batteries in energy storage power stations

- How to install lead-acid batteries in communication base stations

- Photovoltaic power generation capacity of lead-acid batteries in Ouagadougou communication base station

- Application for lead-acid batteries for communication base stations

- Flywheel energy storage power equipment for communication base stations

- Where are the lead-acid batteries for Kyiv communication base stations

- Do lead-acid batteries for communication base stations need to be publicized

- Batteries purchased for energy storage power stations

- Uninterruptible power supply and energy storage for Denmark s communication base stations

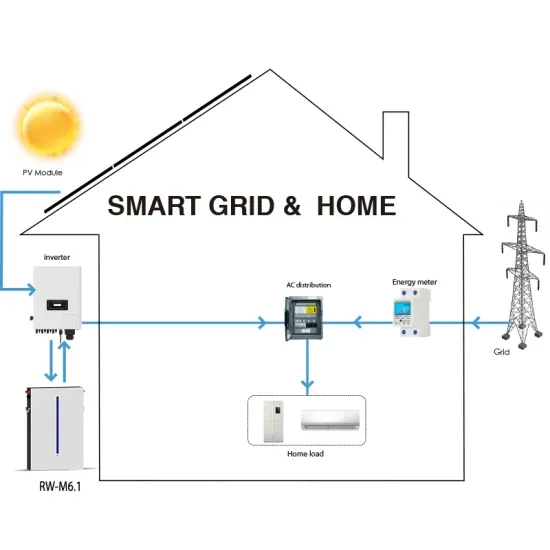

Industrial & Commercial Energy Storage Market Growth

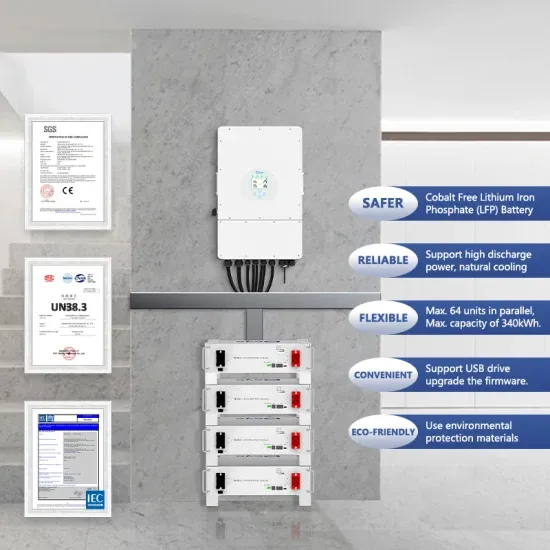

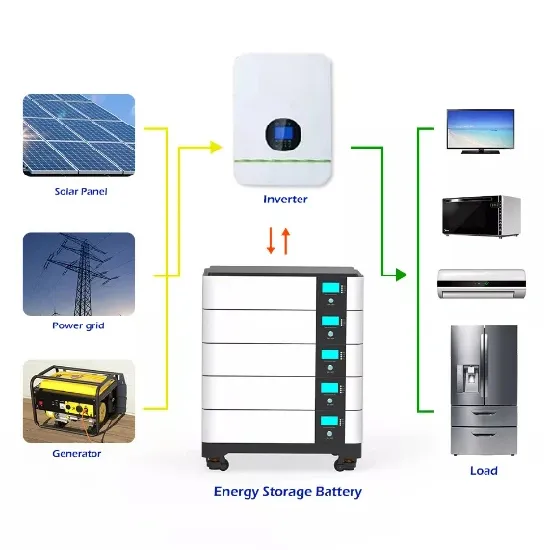

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.